Product introduction

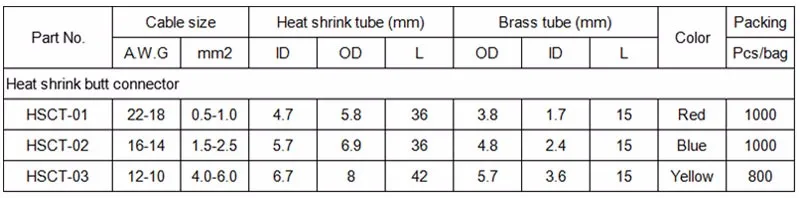

HSCT Insulated Heat Shrink Ring Terminal is made of polyolefin compounded with hot melt adhesive, it has excellent insulation protection, waterproof and anti-corrosion performance. The middle copper tube is high pure purple copper tube with superior conductivity.

HSCT insulation waterproof heat shrink terminal sleeve, it has the advantage of good durablity, easy operation and low installation cost compared with conventional connector.

Product application:

1, Generally applied to electric wire, wire harness, cables and electric connector for protection.2, Applied to rough environment for strengthen the fixed and anti-shock function.

Product feature:

1, Shrink ratio: 3:12,Color: Red, blue, yellow3, PA hot melt adhesive has superior waterproof performance.4, Extension performance is superior, resistance to mechanical damage.5, Good electrical conductivity.6, High elasticity, tube is not easy to deformation.

Operating indicators:

Initial temperature: 80 ℃Min. Shrink temp.: 130 ℃Working temperature: 55 ℃ ~ 125 ℃

Up to standard: ApprovalsAccording with UL224, ROHS

|

Product Property |

Test method |

Test Date |

|

|

Before aging |

Tensile strength |

room temperature |

≥15.9MPa |

|

Elongation |

≥200% |

||

|

After aging |

Tensile strength |

159℃/7 days |

≥11.6MPa |

|

Elongation |

≥100% |

||

|

Voltage withstand and breakdown voltage ( Before aging ) |

room temperature |

2500V,60sec, No breakdown |

|

|

Voltage withstand and breakdown voltage ( After aging ) |

159℃/7 days |

Withstand 2.5KV for 1minute and breakdown at least half of unaged breaddown voltage |

|

|

Copper corrosion |

pass |

||

|

Copper stablity |

No sign of degradation Min.Elongation 100% |

||

|

Cold bend test |

-30℃/3 hrs |

No crack |

|

|

Maximum secant modulus(2%) |

- |

250MPa |

|

|

Volume resistivity |

- |

≥1014Ω-cm |

|

|

Heat shock test |

250℃/4 hrs |

No crack |

|

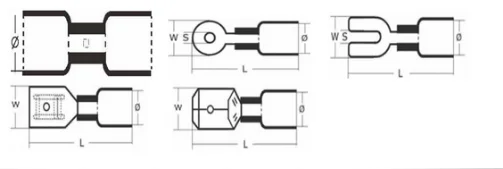

Product drawing: