composite insulator 1 Materials:silicone rubber 2 Delivery: about 20 days 3 Rated voltage: 10-500KV

Our Advantage: We not only produce rubber product, but also rubber machine by ourselves to assure the quality and best price.

Composite Insulator

Product Characters :

1 The silicone rubber sheds adopt overall injection pressure process, so solve the reliability of composite insulators problem of the interface electrical breakdown. The core and the metal fittings using the most advanced technology, high strength, good looks, small size, light weight, corrosion-resistant galvanized fittings, the product structure, reliable, does not damage the mandrel, give full play to its mechanical strength.

2 Excellent electrical properties, high mechanical strength

3 Good stain resistance,and does not require cleaning,re-contamination can run to safety.

4 Small volume, light weight. The structure is dexterous,convient to transport and installation.

5 Silicone rubber sheds with good hydrophobic properties, the overall structure ensures that the insulation does not get wet, no preventive insulation monitoring tests, no cleaning, reducing routine maintenance.

6 Good sealing performance, good resistance to corrosion, with good resistance to aging, corrosion resistance, low temperature resistance, suitable for -40 °C ~ -50 °C areas.

7 Has a strong impact resistance and shock resistance, good anti-fragility and creep resistance, unbreakable, anti-bend, high torsional strength ,can withstand internal pressure, explosion-proof is strong.

Application

The composite suspension insulator is especially suitable for polluted areas, high mechanical tensile load, big span and compact line. It has the characters of light weight, small volume, not easily broken, bending, high torsional strength and explosion-proof performance.

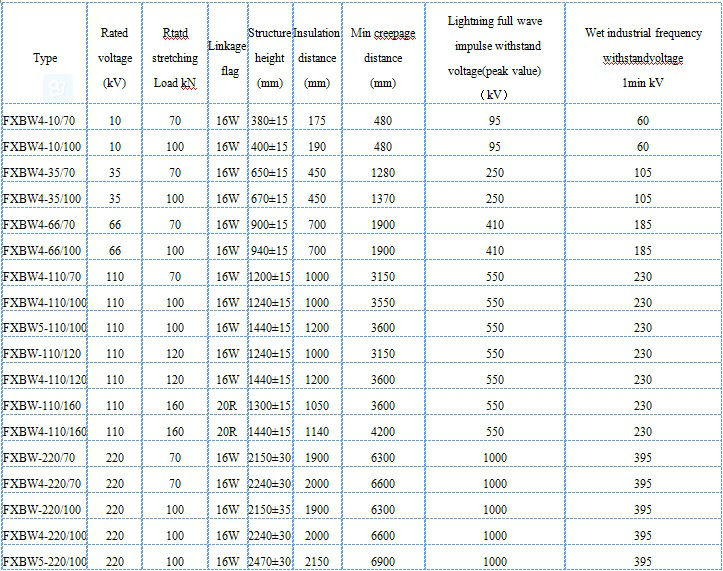

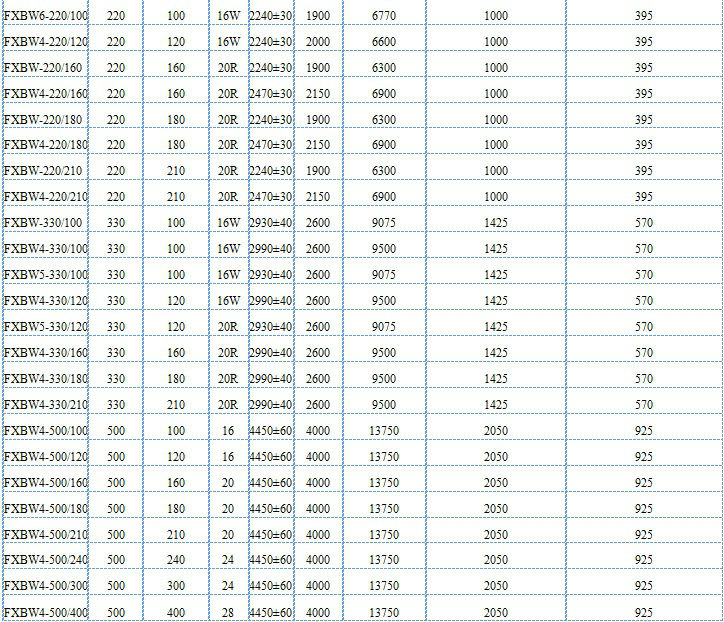

Main Technical parameters:

TYPE EXPLANATION