Basic Company Information

Hengshui Fangchen FRP Equipment Technology Co., Ltd.

Hengshui Fangchen FRP Equipment Technology Co., Ltd.

TEL : 86-318-29963 / FAX : --

No.6 east of Rubber Road, Northern Industry Area, Hengshui, Hebei, China. Hebei Hengshui China [CN]

Homepage : http://www.frpmachine.com

Main Products

Liner Making Machine , Discontinuous Filame , Curing Station for S , Trimming Machine , Extraction Machine

Company Advantage

Hengshui Fangchen FRP Equipment Technology Co., Ltd., located in the No.6 east of Rubber road, Northern industry area, Hengshui, Hebei, China, is a leading company committed to supplying various FRP machines and FRP products. We are a large-scale company integrating design, production and sale for providing one-stop services.

Wide range of products

Various types of FRP machines and FRP products in a variety of designs and sizes are available as shown below:

A picture of Hengshui Fangchen FRP Equipment Technology Co., Ltd.

Hengshui Fangchen FRP Equipment Technology Co., Ltd.

FRP & RPM pipe production line.

Liner making machine.

Discontinuous filament winding machine.

Curing machine.

Trimming machine.

Extraction machine.

Hydro-testing machine.

Microcomputer control system.

FRP vertical tank winding machine.

FRP horizontal tank winding machine.

Pipe fitting winding machine.

Continuous filament winding machine.

Pipe mandrels.

FRP pipe & tank.

High quality products

Our company has talented senior mechanical engineers, experienced artificers, electrical engineers and software engineers that specializing in researching and developing cutting edge FRP machines that perform more stable, operation easier with higher productively and more cost reduction. Meanwhile, our company working with Tsinghua University has developed an advanced control system that provides more accurate control of filament winding equipment.

FRP products manufactured by our machines are durable and long lasting with excellent axial strength. And our FRP products have covered the areas of chemicals, seawater desalination, fermentation industry, agricultural, marine and municipal engineering, etc. Our quality FRP machines and FRP pipe & tank have been sold throughout the Asia market and we began to export our products to India, Vietnam, Russia and various countries from the year 2010. And our quality guaranteed products gain great acknowledgments from our customers.

Excellent service team

The manpower with more than five years of services accounts for nearly 50% of total manpower. Thus, our R&D team is experienced. Meanwhile, our company has professional service team that waiting on line 24/7. Most of all, our service center has a clear organization to solve your different problem.

Front-line customer service staff

They speak English very fluently to handle your inquiries and help you connect to service officer, technical experts or maintenance engineers upon your request.

Customer service officer

They are familiar with your situations and deeply demands, so they can give you the best suggestion of optimal choices. Meanwhile, they give our customers more details about FRP machines and FRP products such as designs and sizes.

Second-tier technical experts

They solve the machine problems on line and handle the problem that customer service officers cannot answer.

Maintenance engineers

They mainly handle your maintenance problems and send your feedbacks to our designer teams.

Detail Company Introduction

Hengshui Fangchen FRP Equipment Technology Co., Ltd., located in the No.6 east of Rubber road, Northern industry area, Hengshui, Hebei, China, is a leading company committed to supplying various FRP machines and FRP products. We are a large-scale company integrating design, production and sale for providing one-stop services.

Wide range of products

Various types of FRP machines and FRP products in a variety of designs and sizes are available as shown below:

A picture of Hengshui Fangchen FRP Equipment Technology Co., Ltd.

Hengshui Fangchen FRP Equipment Technology Co., Ltd.

FRP & RPM pipe production line.

Liner making machine.

Discontinuous filament winding machine.

Curing machine.

Trimming machine.

Extraction machine.

Hydro-testing machine.

Microcomputer control system.

FRP vertical tank winding machine.

FRP horizontal tank winding machine.

Pipe fitting winding machine.

Continuous filament winding machine.

Pipe mandrels.

FRP pipe & tank.

High quality products

Our company has talented senior mechanical engineers, experienced artificers, electrical engineers and software engineers that specializing in researching and developing cutting edge FRP machines that perform more stable, operation easier with higher productively and more cost reduction. Meanwhile, our company working with Tsinghua University has developed an advanced control system that provides more accurate control of filament winding equipment.

FRP products manufactured by our machines are durable and long lasting with excellent axial strength. And our FRP products have covered the areas of chemicals, seawater desalination, fermentation industry, agricultural, marine and municipal engineering, etc. Our quality FRP machines and FRP pipe & tank have been sold throughout the Asia market and we began to export our products to India, Vietnam, Russia and various countries from the year 2010. And our quality guaranteed products gain great acknowledgments from our customers.

Excellent service team

The manpower with more than five years of services accounts for nearly 50% of total manpower. Thus, our R&D team is experienced. Meanwhile, our company has professional service team that waiting on line 24/7. Most of all, our service center has a clear organization to solve your different problem.

Front-line customer service staff

They speak English very fluently to handle your inquiries and help you connect to service officer, technical experts or maintenance engineers upon your request.

Customer service officer

They are familiar with your situations and deeply demands, so they can give you the best suggestion of optimal choices. Meanwhile, they give our customers more details about FRP machines and FRP products such as designs and sizes.

Second-tier technical experts

They solve the machine problems on line and handle the problem that customer service officers cannot answer.

Maintenance engineers

They mainly handle your maintenance problems and send your feedbacks to our designer teams.

Our mission

Three missions of our company are listed in three circles

Company images

An image of the roomy factory of our company

Roomy factory of Fangchen.Various pipes are placed on the floor in front of workshop

FRP pipes in front of workshop.

If you have questions about our products, please email us at info@frpmachine.com. We are looking forward to answering your questions.

Factory Information

Factory Location

Factory Address

No.6 east of Rubber Road, Northern Industry Area, Hengshui, Hebei, China.

Factory Size

50,000-100,000 square meters , Above 50 People

No. of R & D Staff

Above 50 People

No. of Production Lines

10

Annual Output Value

US $50 Million - US $100 Million

Trade Information

Total Annual Sales Volume

US $5 Million - US $10 Million

Export Percentage

41% - 50%

Accepted Delivery Terms

Accepted Payment Currency

Accepted Payment Type

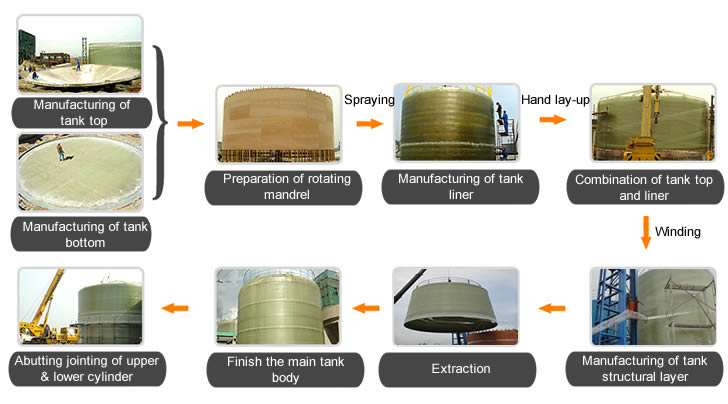

Vertical FRP tank winding machine

Vertical FRP tank winding machine A filament winded vertical FRP tank waiting for extraction.

A filament winded vertical FRP tank waiting for extraction. Vertical FRP tank is demoulded easily using hoist machines.

Vertical FRP tank is demoulded easily using hoist machines.