ZSQ-T100 Online Surface Quality Inspection System for Casting Billet (Eddy Current)

The principle of the system

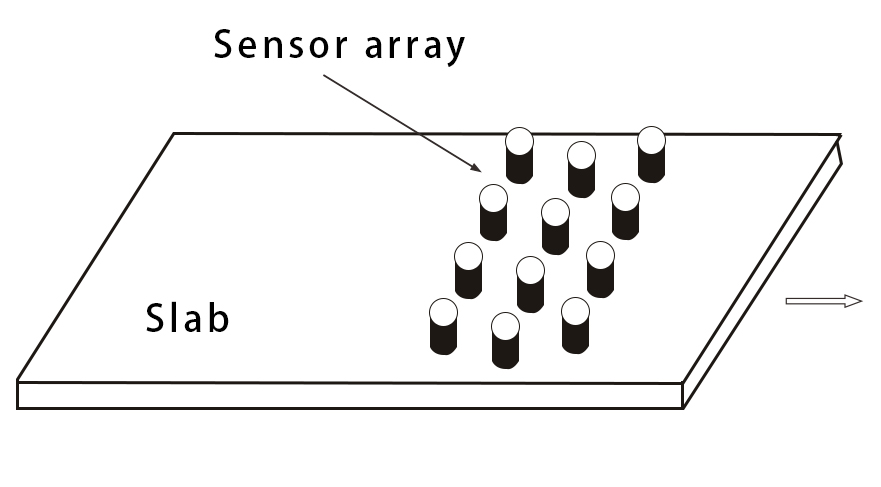

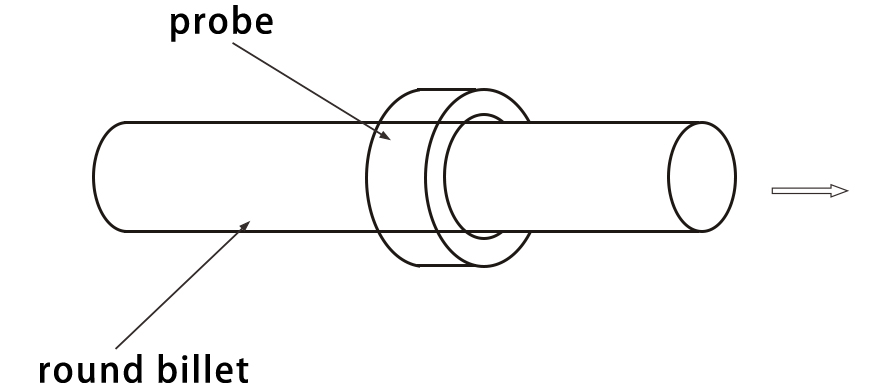

The ZSQ-T100 online surface quality inspection system for casting billet adopts the principle of eddy current non-destructive testing. According to the section of the continuous casting machine and the shape of the casting billet, the eddy current sensors of different structures can be used to realize the non-contact surface defect detection on the surface of the billet, and draws the surface defect graph of the billet in real time according to the detection results.

The composition of the system

The main technical index of the eddy current testing on the surface of continuous casting billets

1. The objects of flaw detection: slabs, round billets, square billets and shaped billets of various sizes.

2. The steel grade of the casting billet: ordinary low-carbon steel or alloy steel.

3. Detection temperature: 400~1000℃.

4. Detection speed: ≤3~40m/min.

5. Allowable speed fluctuation range: 0~40m/min.

6. Detection of defect types and sizes: scratches with a depth or height greater than 1.5mm, wrinkled skin lines, cold splashes, bumps, pits and longitudinal facial cracks, transverse cracks, mesh cracks, and subsurface inclusions with a depth greater than 3mm.

7. Blind spot for flaw detection at the end of the casting billet: 25mm.

8. Detection frame area: ≤3m (transmission line direction)

Wuhan CenterRise M&C Engineering CO., Ltd.

more info, please contact zero zero eight six one three nine nine five five eight eight five nine seven