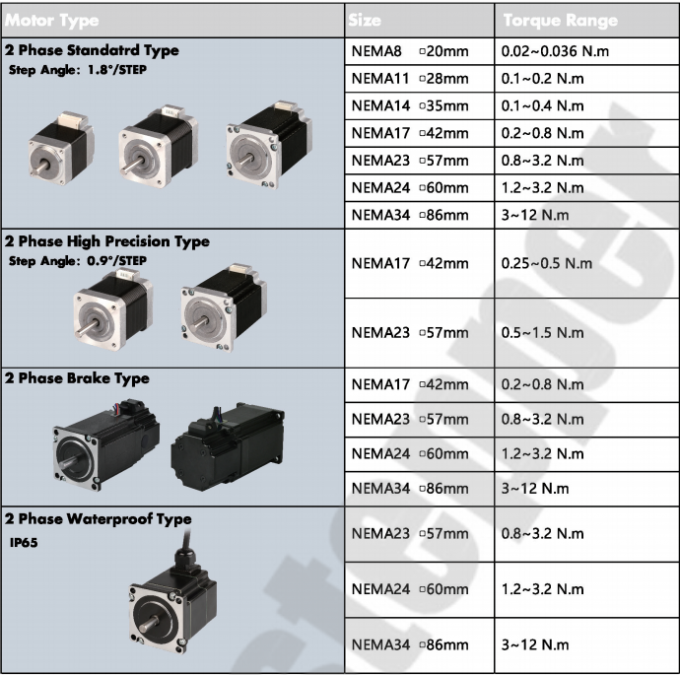

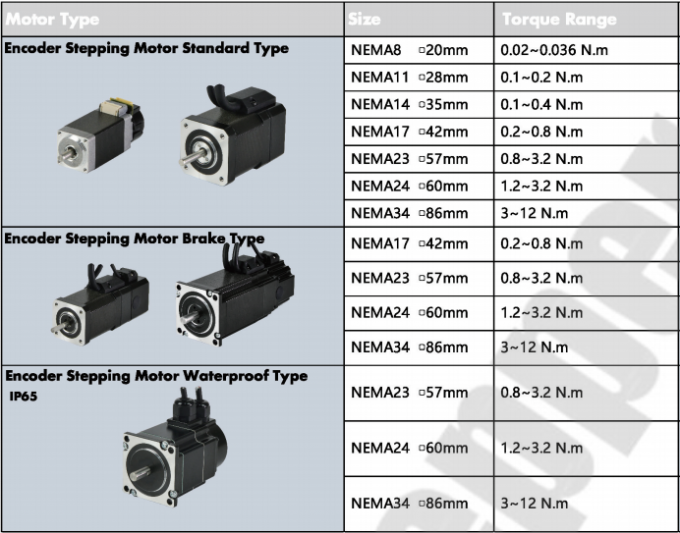

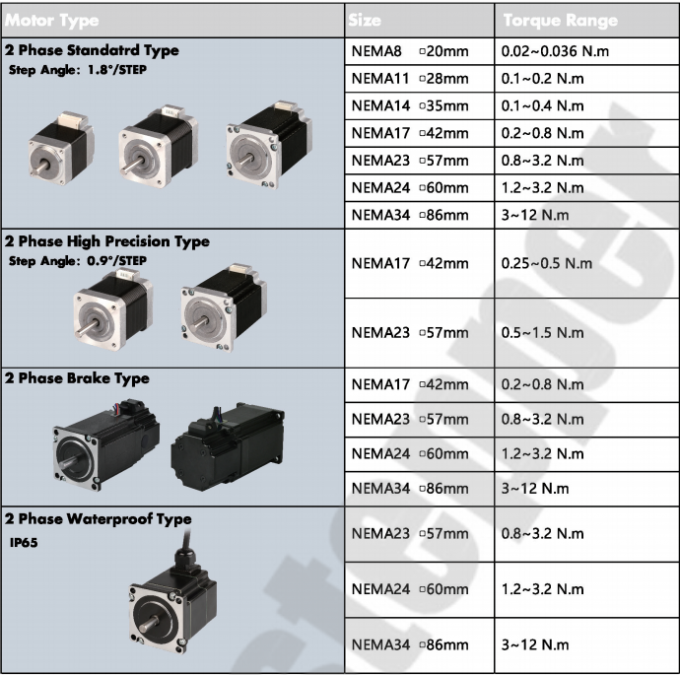

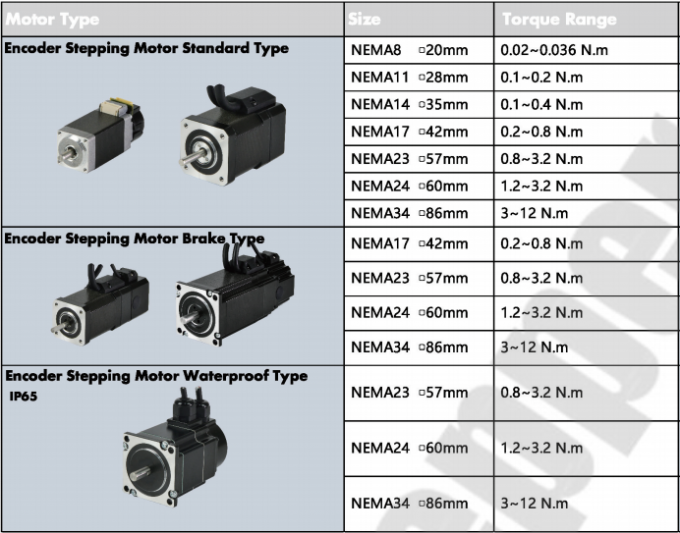

Holding Torque Stepper Motor 2N.M Nema 23 Hybrid Stepper Motor 57mm 1.8 Degree

Description of NEMA23 hybrid stepper motor

- Forward/Reverse Rotation,Pause and Hold

- The forward /reverse rotation of the stepping motor can be controlled by the input sequence of the controlled electric pulses.

- In the case of the a stepping motor lock(the motor winding is energized,there is no external electric pulse command),the stepping motor can still maintain a certain torque output.

- Longer Life

- Stepping motor is a mechanical structure,which does not need be changed by electric brush or Hall sensor,thus reducing the probability and increasing the motor life.Stepping motor life usually determined by the life of the bearing.

- Electromagnetic furnace optimization design, lift torque, reduce temperature rise, so that the motor running smoothly

- Accurate position Control

- The angular displacement of the stepping motor can be precise controlled by the number of electrical pulses.Angle accuracy can be controlled within ±0.09°without any feedback devices.

Hybrid stepper motor's specifications

- Stepping Accuracy: ± 5%

- Resistance Accuracy: ± 10%

- Inductance Accuracy: ± 20%

- Temperature Rise: 80°C Max.

- Ambient Temperature: -20°C ... +50°C

- Insulation Resistance: 100MOhm min. 500V DC

- Withstand: 500V AC, 1 Minute

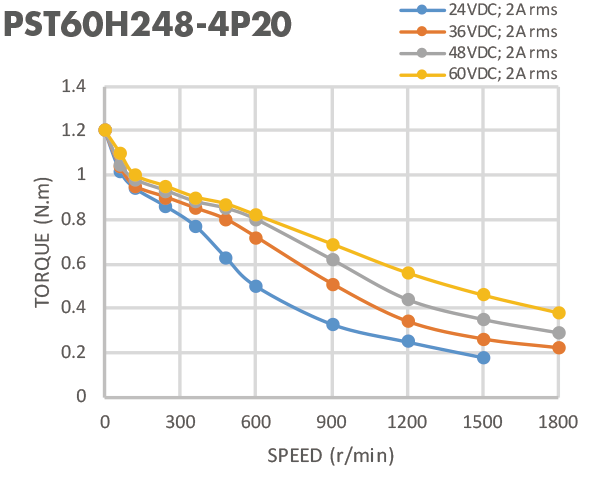

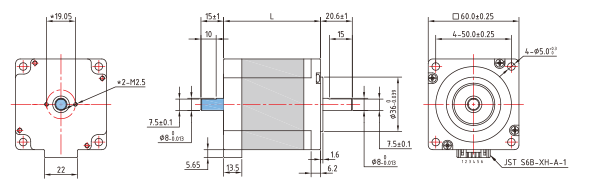

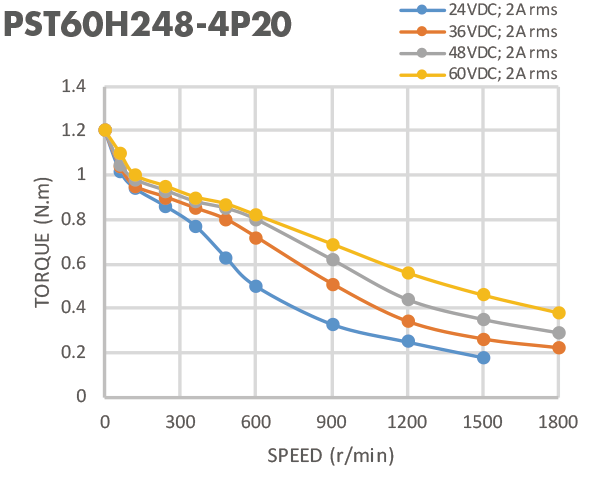

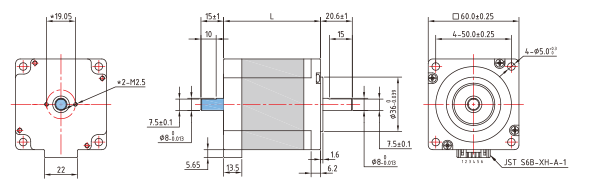

| Mode No | PST60H248-4P20 | PST60H248-4P30 | PST60H248-4L40 |

| Holding Torque | 1.1N.m | 1.1N.m | 1.1 N.m |

| Related Current | 2A/Phase | 3A/Phase | 4A/Phase |

| Resistance | 1.7Ω/Phase | 0.6Ω /Phase | 0.38Ω/Phase |

| Inductance | 3.9MH/Phase | 1.5MH/Phase | 0.78MH/Phase |

| Inertia | 240g.cm2 | 240g.cm2 | 240 g.cm2 |

| Weight | 0.6kgs | 0.6kgs | 0.6kgs |

| Length | 47mm | 55.5mm | 76.5mm |

| Connection | P | P | L |

Applications of 1.8 degree Stepper Motor

- Our products are widely used in 3d and inject printers, CNC routers, Engraving Machines, Stage Lighting Control, Security Surveillance, Video Equipment, Laser workstation, Carving Machine, Office Automation,Smart Toy, Digital Controlled Machinery,Analytical and Medical Instruments, Textile Equipment, Embroidery Machine, Precision Telescope Positioning Systems, High Speed Dome Camera,Robotic and other automatic equipment.

Working principle of stepper motor

- To make the motor shaft turn, first one electromagnet is given power, which makes the gear’s teeth magnetically attracted to the electromagnet’s teeth. The point when the gear’s teeth are thus aligned to the first electromagnet, they are slightly offset from the next electromagnet. So when the next electromagnet is turned ON and the first is turned OFF, the gear rotates slightly to align with the next one and from there the process is repeated. Each of those slight rotations is called a step, with an integer number of steps making a full rotation. In that way, the motor can be turned by a precise. Stepper motor doesn’t rotate continuously, they rotate in steps. There are 4 coils with a 90o angle between each other fixed on the stator. The stepper motor connections are determined by the way the coils are interconnected. In a stepper motor, the coils are not connected. The motor has a 90o rotation step with the coils being energized in a cyclic order, determining the shaft rotation direction. The working of this motor is shown by operating the switch. The coils are activated in series in 1-sec intervals. The shaft rotates 90o each time the next coil is activated. Its low-speed torque will vary directly with current.

How to overcome the vibration and noises of 2-phase hybrid stepper motor when rotating at low velocity?

The vibration and noise of the stepper motor rotating at low velocity its the intrinsic defects, which can be generally overcome by adopting following schemes:

- If the stepper motor works at resonance region, the resonance region can be evaded by changing mechanical transmissions such as velocity ratio.

- Use subdivided driver, which is the most common and simple method.

- Replace for the stepper motor with smaller stepping angle, like 3-phase or 5-phase stepper motor.

- Replace for AC servo motor, which can nearly overcome vibration and noise, but the cost is quite high.

- .Add magnetic damper to the shaft of motor, such product has been available in the market, but the mechanical structure is changed a lot.

Buter's concern

1. All stepper motors have CE and RoHS certification

2. All motors are tested by a toasting machine for 72 hours

3. All the motors will be shipped after testing

Can you make the motor with customized requirement ?

YES. We have experienced R&D capability and great engineers, Their experience and innovation capability can support customized project.

2. Can you provide the samples?

YES. We can provide the samples, The delivery time is about 7-15 days according to which kind of motor you want

3. What is your MOQ?

It's accordingly to the motor type you order, Our MOQ for gear motor can even 1pc.