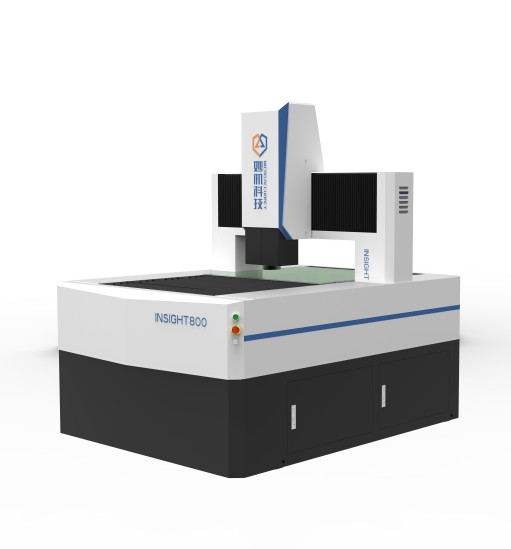

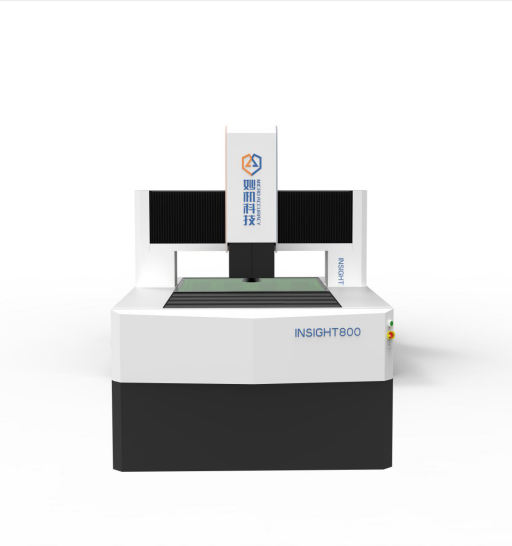

CNC multi-sensor Coordinate Measuring Machine is high precision measurement solutions for large parts. With available Metrology Software, Programmable auto-lens, Servo motion control, the coordinate video machine measure parts up to 2 meters.

CNC multi-sensor Coordinate Measuring Machine is the ideal model for larger LCD, LED, PCB, Film and Large glass products inspection. Working with professional CNC Metrology software and Auto-lens satisfies various sizes measurements.

CNC multi-sensor Coordinate Measuring Machine are also widely used with multiples of smaller parts nested in a fixture.

CNC multi-sensor Coordinate Measuring Machine Features

1. DIN 000 grade granite table master base guarantees strength, accuracy and stability

2.0.0005mm resolution RSF or Renishaw self-adhesive metal grating on X and Y axis ensure the accuracy and long life

3. 0.7X-4.5X Auto-Lens as standard satisfies various sizes measurements without re-calibration

4. HDMI Gigabit Ethernet Industrial Camera

5. Programmable surface cold-light source and contour parallel source is used to enhance the performance of illumination.

6. Fast Servo Motor Control

7. Fast and accurate Z measurements with Vision

8. Powerful Metrology software is simple to use, combination with joystick, keypad and mouse

9. The Vision Systems are Probe-ready (option), including UK RENISHAW contact probe and Japan Keyence CCD laser probe

Technical data

| Item No. | INSIGHT800 |

| Stage Travel X-axis | 800mm |

| Stage Travel Y-axis | 600mm |

| Stage Travel Z-axis | 200mm(focus) |

| Feed mechanism | CNC |

| Resolution | 0.5µm RENISHAW SCALE |

| Measuring Accuracy | (2.5+L/200) µm |

| Repeatability | 0.002 mm |

| Load | 50kg |

| Video System | CCD Camera:Gigabit Ethernet Industrial Camera Zoom Lens : 0.7X-4.5X Auto-Lens |

| Illumination | Contour illumination: traceable LED lamp Surface illumination: Programmable LED ring light |

| Power | AC110/220V, single phase 50/60Hz Total power 400W |

| Environment | (20 ± 2 ) °C ; 55% ~ 65% |