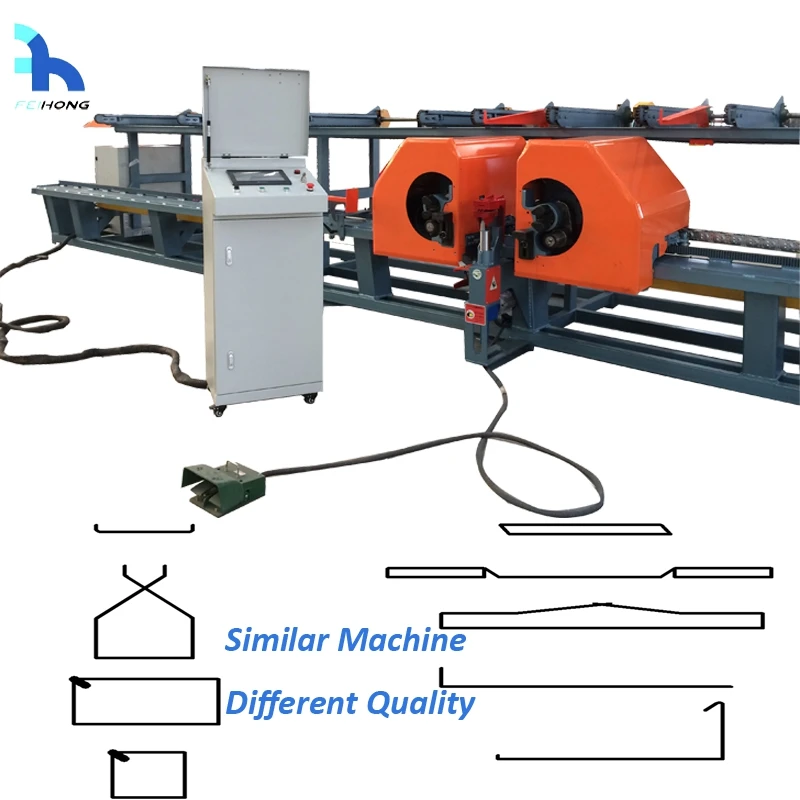

Rebar Bending Line – –

Our Company uses the newest rebar bending machine to bend the rebars as per the requisite sizes and shapes. First and foremost, the safety precautions are made and then the machine is set to keep up a correspondence to the size of rebar to be used. Rebar is placed in the rebar bending machine which is fully controlled by CNC. The machine has the capability of bending rebars in different shapes up to 40mm.

Technical Parameters----Rebar Bending Line

|

Bending Speed

|

30°-48°/S(5-8r/min)

|

|

Overall Weight

|

4.5tons

|

|

Min Length scope of the stirrup side

|

70mm

|

|

Max bending angle

|

Upward bending 0-200°/Downward bending 0-120°

|

|

Bi-directional bending (up or down bend)

|

Φ10mm-Φ28mm

|

|

Unidirectional bending (upward bending)

|

Φ28mm-Φ32mm

|

|

Min. Space between stirrup side

|

¢10 560mm ¢32 620mm

|

|

Max bending length

|

10.5m

|

|

Feeding speed of storage convey table

|

0.6m/s

|

Features of steel wire bending machinery Rebar Bending Line

♦♥.Servo motor and PLC control system, stability, precision accuracy.

♦♥.Equipped with a liquid crystal display(LCD), the entire process uses a visual graphical input interface, easy to operate.

♦♥. The bending spindle adopts spline design. Made of high-quality alloy steel which is made by special technology, featuring high strength, wear resistance and long service life, providing sufficient torque output for rebar processing.

♦♥. Double bending head bending machine can realize the continuous bi-directional bending of the same work surface, which greatly ensures the quality of the finished product.

♦♥.Special custom-made the bending mould according to the customer's drawing is available

♦♥.It can process Φ10-32mm rebar.

♦♥.Storage mechanism equipped with a buffer waiting hook, it can place the rebar material to wait for the next bending operation, and it can improve the efficiency of feeding, speeding up the bending work schedule of next unit, easy manual operation.