| Model | OR-P 3015 | OR-P4020 | OR-P6020 |

| Working Area | 1500*3000mm | 2000*4000mm | 2000*6000mm |

| Applicable Materials | Stainless steel, carbon steel, alloy steel, spring steel, copper, aluminum, gold, silver, titanium and other sheet metal products. | ||

| Materials Thickness | Max 40 mm | ||

| Laser Power | 4000w/5000W/8000W/12000w | ||

| Laser source | IPG/RAYCUS/MAX | ||

| Laser head | RAYTOOLS/PRECITEC | ||

| Dimensions(L*W*H) | 9950*3050*2100mm | 11000*3600*2100mm | 13600*3600*2100mm |

| Weight | 8000kg | 10000kg | 11500kg |

| Repeat Positioning Accuracy | ±0.02mm | ||

| Accuracy of Positioning | ±0.03mm | ||

| Max. Movement Speed | 170m/min | ||

| Max. cutting Speed | 140m/min | ||

| Max Acceleration | 1.5G | ||

| Power consumption | <10KW | ||

| Specified voltage and frequency | 380V/50Hz/60Hz/60A(Customizable) | ||

Safer and more efficient

Protective optical fiber laser cutting machine with totally enclosed laser protective outer garment, cast iron bed, chain exchange platform, professional CNC cutting system, provides users with powerful cutting ability and efficiency.

Meanwhile, the top-class imported parts and strict assembly process guarantee the stable operation of the machine with safe, efficient and high precision.

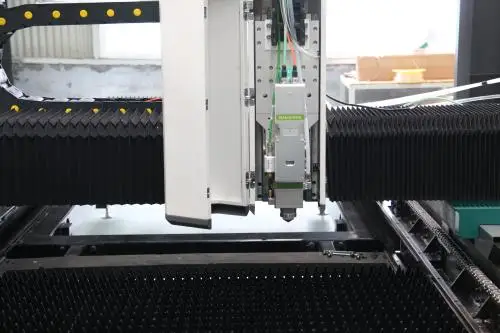

Laser head- Automatic focusingbased on the working distance of the laser head.It automatically adjusts the height of the laser head according to the distance from the cutting workpiece. |

|

|

Protective coverThe protective cover of laser cutting machine has the characteristics of strict structure, reasonable, no noise, more safety ,large stroke, fast movement and long service life. |

Laser power, wattageThe power of each laser can be changed according to the specific cutting requirements.

For different metal materials, the cutting thickness of different power laser cutting machines has a great relationship with the cutting material

|

|

|

Automatic oiling system According to the timing required by machinery and equipment to quantitatively fill oil,maintain its lubriction status; increase the service life of the machine;reduce the maintenance time of machinery and equipment,directly increase the use's income. |

Exchange platformThe machine is equipped with an exchange double table. The sheet workpiece can be loaded and unloaded at the same time as the cutting process. The table is equipped with a rotatable ball support to facilitate the movement of the plate. |

|

1.5kw fiber laser cutting machine metal sheet applied:

Stainless steel, carbon steel, alloy steel, spring steel, copper, aluminum, gold, silver, titanium and other sheet metal products.

Widely used in advertising, high pressure / low voltage electrical cabinet production, textile machinery parts, kitchen utensils, automobiles, machinery, elevators, electrical accessories, spring coils, subway line parts and other industries

Service

The after-sales service of OREELASER

1. 12 languages 24 hours Quick Feedback;

2. "Training Video", "Instruction Book", and "Operation Manual" will be offered;

3. Brochures for simple trouble-shootings of the machine is available;

4. Plenty of technical support online is available;

5. Quick Back-up Parts Available & Technical Assistance;

6. Free training service is available.

Each product from Oree Laser is strictly examined according to ISO9001 (QCS) standard

before it is put on to the market. Many laser equipment series have acquired CE, FDA and RoHS certificate.

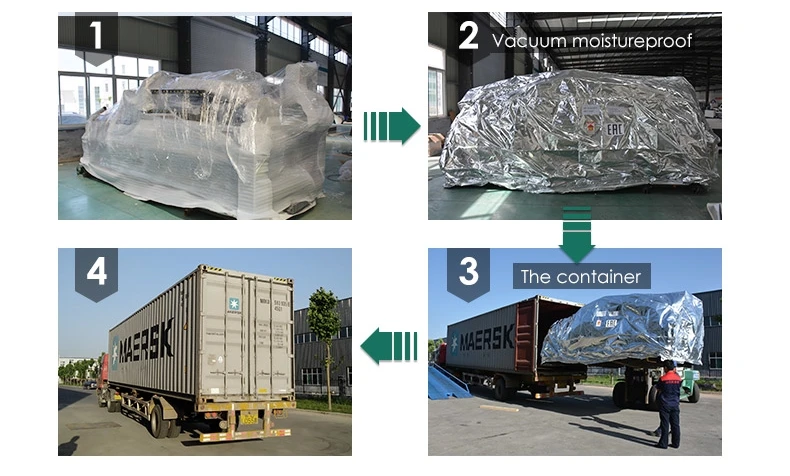

Professional package of laser cutting machine:

1. Whole film packaging machine;

2. Anti-collision package edge;

3. Fumigation-free plywood wooden box and pallets with iron binding belt.