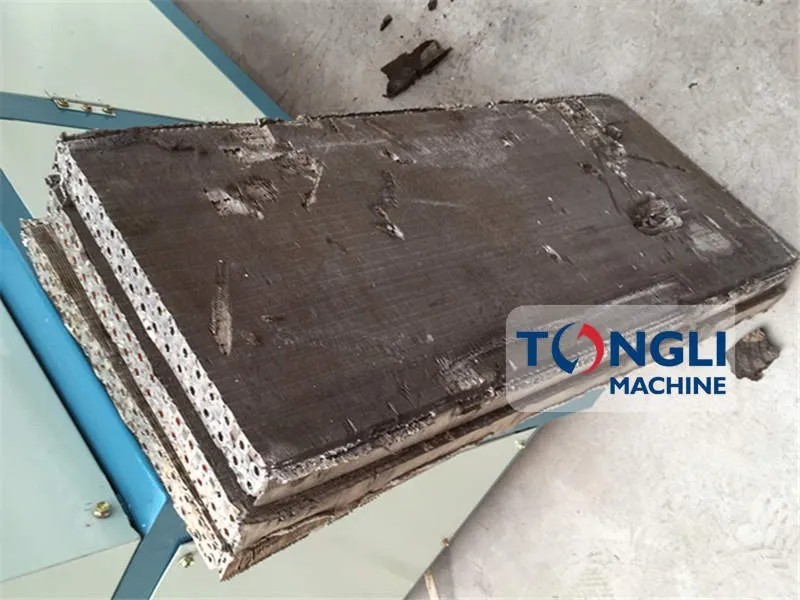

The Radiator recycling machine and copper and aluminum separating machine is used to strip and separate the single-layer and double-layer radiator fin.

The machine is created of motor, reduction box, rack, press roller, blade, pinch roller, etc.

The copper and aluminum of the radiator are separated by cutting blade. After that, the copper pipe stay

unaffected, and the aluminum have irregular pieces. When the engine starts, the vee belt drives the

compression roller, pinch roller, and blade to rotate through the reduction box. The compacted raw material is

sent to the fly-cutter blade by pinch roller. Then, the radiator is cutted up by the fly-cutter blade, the copper

pipe is separated, and the aluminum scattered network cuts up .

Technical Data

|

Car Radiator Recycling Machine |

|

|

Engine Power |

3 KW + 4 KW |

|

Voltage |

380 V or Customized ( 50 HZ / 60 HZ ) |

|

Cutting Width 1 |

19 mm * 9 paths |

|

Cutting Width 2 |

21 mm * 11 paths |

|

Cutting Width 3 |

25 mm * 14 paths |

|

Cutting Speed |

13 m/min |

|

Dimension |

1700*860*1200 mm |

|

Band Saw |

|

|

Engine Power |

2 KW |

|

Dimension |

800*460*1800mm |

Material : the radiator whose copper tube center distance is 19mm, 21mm or 25mm.

First , cut the iron sheets on the sides of the radiator by band saw . Then pass through the radiator recycling

machine . Finally , get the copper and aluminum .

The scrap radiator fin should be put into the inlet smoothly and the stripped copper pipes and aluminum foil

can be discharged automatically. After being separated, the copper tube will keep complete and the aluminum

foil will become irregular pieces.