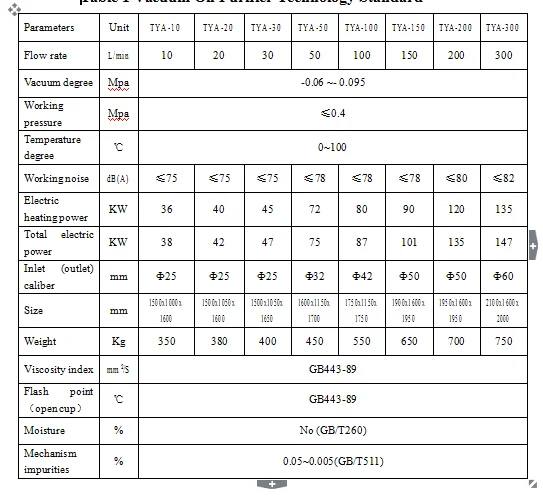

2017Cost Effective Highly Efficient Lubricant Oil Purifier Machine Made By ZHONGNENG

Note: Lubricant Oil Purifier Machine

1.Easy installation and operation;

2.Energy saving and low operating cost;

3.Little maintenance and overhaul reduction;

4.Operates unattended.

TYA Series lubricant oil purifier machine is specialized for the lubricant oil which water content is very high, hydraulic oil, refrigerating machine oil and another lubricant oils which need to remove a lot of water to realize to filter the little tiny impurities.

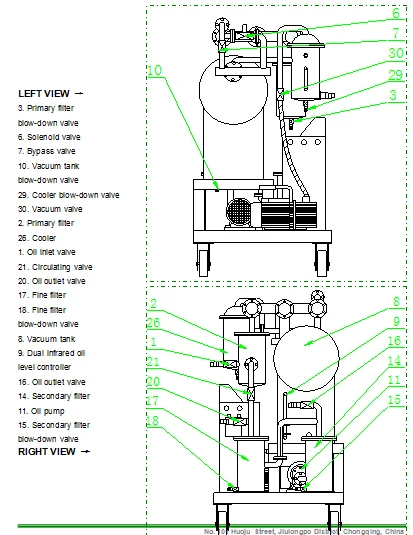

1.Double primary-filter structure, large capacity for holding particles, Multi-stage filtration system to ensure high filtration precision.

2. Special polymer materials as filter medium with the functions of broken emulsion, dewatering, removing particles.

3.Duplex-Stereo film evaporation technology, equips with unique and advanced dewatering, degassing components, can rapidly and effectively remove water, gas, particles and volatile matter (such as alcohol, gasoline, ammonia, etc.)

4. Automatic backwashing system, improving working efficiency

5. Advanced medium condensing radiator.

6. High quality filtering components, large capacity for holding particles, anti-corrosion, good mechanical performance, long lifetime.

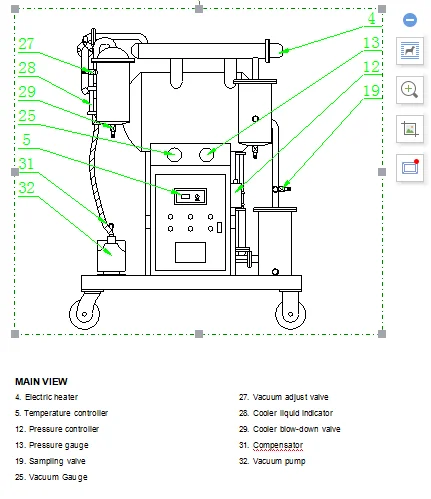

7. Efficient electric heating system, heating uniformity, less power consumption, safe, and reliable.

8. Adopts interlocked protective system, which connect oil pump, heater and liquid level sensor, avoiding blank heating, blank pumping, oil leak and electricity leak. If there is any fault, machine will be power off automatically.

Advance Technology

1. Duplex stereo-evaporation technology and G technology;

2. Special impurity-removing technology that combines double FH trapezoidal network and high polymer adsorbing materials instead of the traditional technology of simple network;

3. Double infrared fluid level auto-control system replaces manual or floating valve control;

4. German 3UG3 phase relay;

5. A trinity of interlocked preventive device;

6. The lifetime of oil purifier can be dramatically prolonged by application of advanced dielectric condensation device;

7. Carbon fiber infrared heating system;

8. Trapezoidal spiral filter elements make automatic removing impurities and back flushing system.possible.

f automatically.

|

Item |

Guarantee indexes |

|

Moisture content |

≤50 PPM |

|

Demulsification value |

New oil≤15min,running oil≤30min |

|

Impurity size |

≤1 micron |

|

Gas content |

≤0.1% |

1. TYA Lube Oil Purifier(regular model);

2. TYA-A Automatic Vacuum Lube Oil Treatment Machine (with PLC control system/ touch screen);

3. TYA-EX Explosion-proof Lubricating Oil Purifier (with anti-explosion design);

4. TYA-H Vacuum Hydraulic Oil Purifier;

5. TYA-I Phosphate Ester Fire-resistant Oil Purifier;

6. TYA-M Enclosed Mobile Vacuum Lube Oil Purification Plant (with trailer);

7. TYA-RD Vacuum Lube Oil Regeneration System (with regeneration device);

8. TYA-PL Vacuum Lube Oil Filtration System (with plate pressure oil purifier);

9. TYA-S Stainless Steel Lube Oil Filtration Unit;

10. TYA-WP Enclosed Weather-proof Vacuum Oil Purifier (with enclosed structure);

11. TYA-WS Lube Oil Water Separator (with high-efficiency plate type radiator).

1. ZY series single-stage vacuum transformer oil purifier;

2. ZYD series double stage transformer vacuum transformer oil; 3. TY series vacuum turbine oil purifier machine;4. LYE series waste engine oil recycling system;5. BOD series waste oil distillation & converting system for base oil;

7. DOD series waste oil distillation & converting system for gasoline/diesel;

8. TYB series coalescence-separation oil purifier;9. CYA series centrifugal oil purifier;10. PL series plate pressure oil filtration unit;11. JL series portable oil purifier;12. IIJ-II series transformer oil dielectric strength tester.

(oil purifier, oil purifying, oil purification, oil filtration, oil filter, oil filtering, oil recycling, oil treatment, oil processing, oil dehydrator, oil regeneration, oil restoration, oil filtering, oil dewatering, oil dehydration, impurity removing, oil reprocessing, waste oil disposal, oil water separator, oil reclaiming, waste oil management, oil reconditioning, oil recondition, oil reconstituted, oil restituting, oil recovering ,oil filtrating,oil processing, oil dehydrating, oil degasing, oil recovery, oil reclaiming, oil reclaimation, oil converation, petroleum machine)

Tel:0086 23 68060921

www.zhongnengcq.com

www.zhongnengcq.com