1.Overview

1.1Application

The CCB type eat hutch slurry pump is developed based on the latest technologies and on experiences of water pump usage in China, and is reliable and easy to maintain. Its life time is much longer than that of screw pump and sump well pump. It is widely used to transfer eat hutch waste slurry, waste water, lipids, etc. Particles sizes up to ¼ of the pump bore size can be transferred due to its anti-clogging structure of large channel. Container type mechanical seal could also be installed for the auxiliary impellers to ensure no leakage while running.

1.2 Operation Parameters

Rotation rate: 980, 1480, 2950 (r/min)

Voltage: 380 V

Inlet and outlet bore size: 50 – 300 mm

Temperature: ≤ 150 ℃

Percentage of solid in the slurry: ≤ 25%

1.3 Nomenclature of Model Name

An example model name, 100CCB90-25, is used to explain its nomenclature:

100 --- Inlet and outlet bore size

CCB --- Eat hutch slurry pump

90 ----- Designed capacity at 90 m3/h

25 ----- Designed head of 25 m

F ------- An auxiliary impeller seal

1.4 Performance

Capacity: 3 ~720 m3/h

Head: 10 ~100 m

1.5 Work Conditions

|

Bore size |

50 |

65 - 80 |

100 - 125 |

150 - 200 |

250 -300 |

|

Particle size |

< 10 |

< 20 |

< 25 |

< 30 |

< 50 |

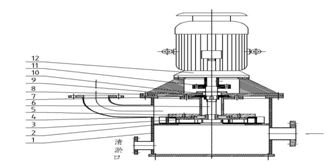

2.Structural Features

CCB eat hutch slurry pump has the following technical advantages:

(a)The impeller is of semi-open type, which increases pumping efficiency by 10 ~15% compared with those traditional screw pump or sump well pump, hence the motor power needed could be one grade down which will in return save energy consumption. Furthermore, the impeller is more cavitation-resistant.

(b)The sealing system consists of auxiliary impeller sealing and power-off sealing based on a serial of fluid power, and is designed for frequent start/stop usage.

(c)The pump is linked directly to the motor. The impeller rotates clockwise when viewed from the motor end.

(d)There is a special desilting case at the bottom of the pump to collect precipitants which cannot be discharged from the outlet but could be removed through the door on the case.

3. Materials Of Main Components

|

Pump body |

Impeller |

Shaft |

Sealing ring |

Auxiliary Impeller |

Bearing Spider |

Base Plate for Motor |

|

1Cr18Ni9Ti |

Cr26 alloy |

1Cr18Ni9Ti |

Cr26 alloy |

1Cr18Ni9Ti |

1Cr18Ni9Ti |

Q235-A |