MP-10KV Polyolefin Heat Shrink Busbar Insulation Tubing/High Voltage Heat Shrink Tube For Terminals And Busbar

MP-10KV Polyolefin Heat Shrink Busbar Insulation Tubing/High Voltage Heat Shrink Tube For Terminals And Busbar, known as copper bar protection tube, is made of cross-linked environmental protection polyolefin PE heat shrinkable materials which is bombarded by high power electron beam. The product with good resistance to bending and scratching, high insulation strength and resistance to electric carbon mark, applies to switchgear, substation bus, busbar, electrical equipment for anti-corrosion and insulation protection. It’s widely used in electric power industry.

Features & Benefits:

1, resistance to flame and corrosion.

2, with superior insulated and chemical properties.

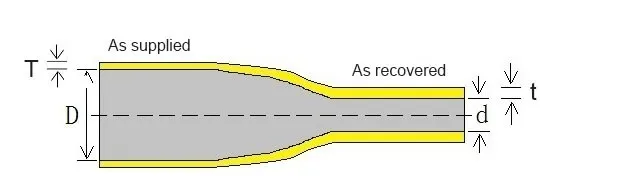

3, Shrink ratio: 2:1 (1 kV, 35 kV, 10 kV busbar )

4, environmental friendly, high strength, good elasticity, flame-resistant, soft.

Operation Indexes:

Min. Shrink temp.: 80℃

Final shrink temp.: ~120℃

Operating temp.: -55℃~125℃

Up to standard: Approvals

Meet RoHs compliant

|

Product Properties |

Performance requirements |

Test Date |

|

Cold bend flexibility |

-30℃×4H |

No cracking |

|

Tensile Strength |

ASTM D 2671 |

≥11Mpa |

|

Elongation at break |

ASTM D 2671 |

≥400% |

|

Tensile strength after heat aging (168hrs at136℃) Elongation at break after heat aging (168hrs at136℃) |

ASTM D 2671 |

≥10 MPa

>300% |

|

Low temperature flexibility4hrs at-40℃ |

ASTM D 2671 |

No cracking |

|

Heat shock 4hr at 200℃ |

ASTM D 2671 |

No drop no flow |

|

Dielectric strength |

ASTM D 2671 |

20kv/mm |

|

Volume resistivity |

ASTM D 2671 |

10x1014Ω.cm |

|

Water absorption 336hrs at 23℃ |

ASTM D 570 |

<0.5% |

|

Copper corrosion 158℃ for 168hrs |

IEC 60684-3 |

No cracking |

|

Color fastness to light |

IEC 60684-3 |

Contrast between exposed and unexposed parts ,The color does not change. |

|

Part Number |

Basbar width(MM) |

As supplied(MM)) |

After recovered(MM) |

Standard ength(m/roll) |

||

|

Inner diameter (D) |

Wall thickness (T) |

|

||||