KY-HB Wire Harness Insulation Polyolefin Single Wall Heat Shrinkable Tubing

KY-HB Wire Harness Insulation Polyolefin Single Wall Heat Shrinkable Tubing is made of polyolefin material, has the function of insulation and protection.It applies to electric components, coating of the wire harness,and protection of the terminal junction of the electric wire and cable, at the same time, it also has the function of color identification. It’s widely used in electrics, electronic industry, electrical industry, etc.

Features & Benefits

1, Soft, insulate, low-temperature shrink, flame-resistant (except for the transparent)

2, Have good physical, chemical and electronic properties

3, No halogen, environmentally friendly

4, Shrink ratio: 2:1

5, Vertical Shrink ratio:≤±5%

Operating Indexes

1,First Shrink Temp.:75℃

2,Final Shrink Temp.:115℃

3,Working Temp.:-55℃~125℃

Up to standard: Approvals

Meet UL224 125℃ 600V VW-1

|

Product Properties |

Performance requirements |

Test Date |

|

|

Tensile Strength |

GB/T 1040 |

≥10.4MPa(Before heat aging) |

|

|

158℃×168h |

≥7.3MPa(After Heat aging) |

||

|

Elongation at break |

GB/T 1040 |

≥200%(Before aging) |

|

|

158℃×168h |

≥100%(After aging) |

||

|

Heat shock resistance |

250℃×4h |

No cracks and do not be sticky |

|

|

Heat cold bend resistance |

-30℃×4h |

No cracks |

|

|

Breakdown strength |

GB/T 1408 |

≥15kv/mm |

|

|

Withsatand boltage |

600V |

2500V,60s, No breakdown |

Pass |

|

300V |

1500V,60s No breakdown |

Pass |

|

|

Volume resistivity |

GB/T 1410 |

≥1×1014Ω.cm |

|

|

corrosion resistance |

158℃×168h |

Pass |

|

|

Copper stability |

158℃×168h |

Pass |

|

|

Flame resistivity |

VW-1 |

Pass |

|

|

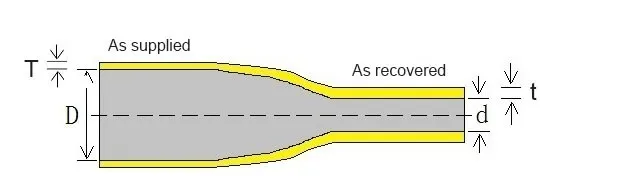

SIZE(MM)

|

As supplied (mm) |

After recovered |

Standard Length(Meter) |

Application Range(mm)

|

||

|

Inner diameter(D) |

Wall Thickness(T) |

Inner diameter ( d ) |

Wall thickness ( t ) |

m/roll |

||

|

φ0.6 |

0.9±0.2 |

0.20±0.05 |

≤0.40 |

0.33±0.10 |

200 |

0.5~0.7 |

|

φ0.8 |

1.1±0.2 |

0.20±0.05 |

≤0.50 |

0.33±0.10 |

200 |

0.6~0.8 |

|

φ1.0 |

1.5±0.2 |

0.20±0.05 |

≤0.65 |

0.36±0.10 |

200 |

0.75~0.9 |

|

φ1.5 |

2.0±0.2 |

0.20±0.05 |

≤0.85 |

0.36±0.10 |

200 |

0.95~1.4 |

|

φ2.5 |

3.0±0.2 |

0.25±0.05 |

≤1.30 |

0.45±0.10 |

200 |

1.4~2.3 |

|

φ3.0 |

3.5±0.2 |

0.25±0.05 |

≤1.50 |

0.45±0.10 |

200 |

1.6~2.7 |

|

φ2.0 |

2.5±0.2 |

0.25±0.05 |

≤1.00 |

0.45±0.10 |

200 |

1.1~1.8 |

|

φ3.5 |

4.0±0.2 |

0.25±0.05 |

≤1.80 |

0.45±0.10 |

200 |

1.9~3.2 |

|

φ4.0 |

4.5±0.2 |

0.25±0.05 |

≤2.00 |

0.45±0.10 |

200 |

2.1~3.6 |

|

φ4.5 |

5.0±0.2 |

0.30±0.08 |

≤2.30 |

0.56±0.10 |

100 |

2.4~4.0 |

|

φ5.0 |

5.5±0.2 |

0.30±0.08 |

≤2.50 |

0.56±0.10 |

100 |

2.6~4.5 |

|

φ5.5 |

6.0±0.2 |

0.30±0.08 |

≤2.75 |

0.56±0.10 |

100 |

2.85~5.0 |

|

φ6.0 |

6.5±0.2 |

0.30±0.08 |

≤3.00 |

0.56±0.10 |

100 |

3.1~5.4 |

|

φ7.0 |

7.5±0.3 |

0.30±0.08 |

≤3.50 |

0.56±0.10 |

100 |

3.7~6.3 |

|

φ8.0 |

8.5±0.3 |

0.30±0.08 |

≤4.00 |

0.56±0.10 |

100 |

4.2~7.2 |

|

φ9.0 |

9.5±0.3 |

0.30±0.08 |

≤4.50 |

0.56±0.10 |

100 |

4.7~8.0 |

|

φ10 |

10.5±0.3 |

0.30±0.08 |

≤5.00 |

0.56±0.10 |

100 |

5.2~9.0 |

|

φ11 |

11.5±0.3 |

0.30±0.08 |

≤5.50 |

0.56±0.10 |

100 |

5.7~10 |

| .... | ... |

... |

... | ... | ... | ... |

|

φ210 |

≥210 |

0.65±0.30 |

≤105.0 |

1.30±0.30 |

25 |

110~205 |

|

φ230 |

≥230 |

0.65±0.30 |

≤115.0 |

1.30±0.30 |

25 |

120~225 |

|

φ250 |

≥250 |

0.65±0.30 |

≤125.0 |

1.30±0.30 |

25 |

130~240 |

Colors: Black, white, red, blue, yellow, green

Pointed size and cutting according to the requests of customer

Avg. Wall thickness = (max. Wall thickness + min. Wall thickness)/2