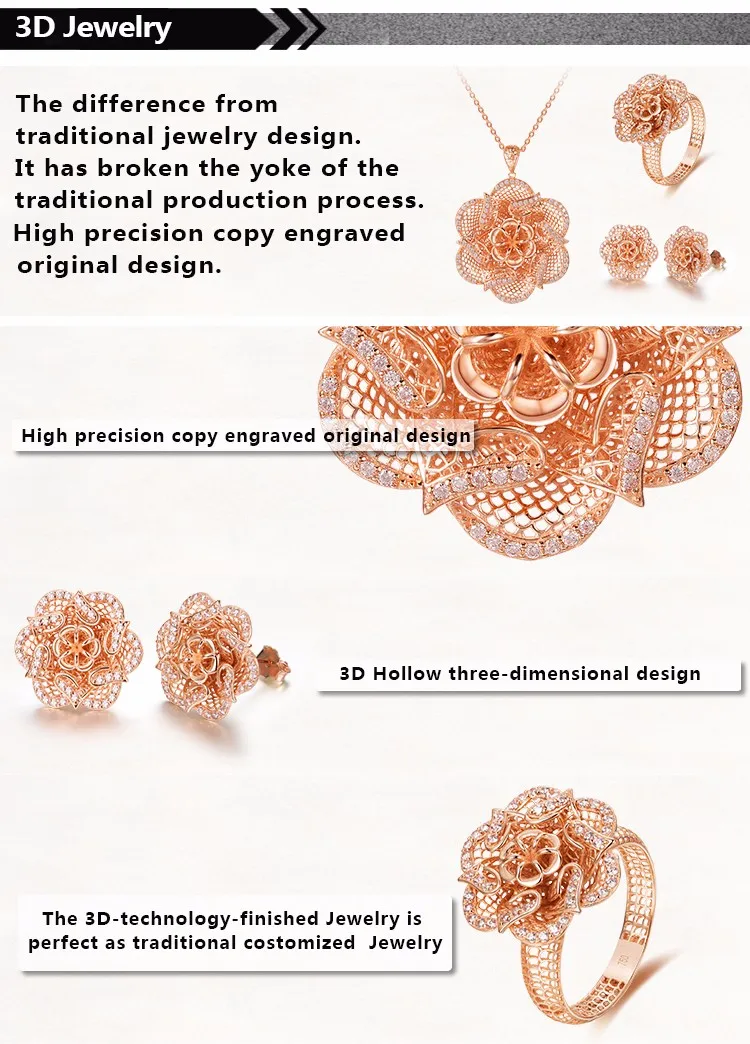

Jewellery Meets 3D Printer

Better Printing, Better Casting.

The best jewellery inspiring our future is through the power of 3D printing technologies. 3D printing with castable resins are specifically designed for direct lost wax casting of jewelry models. Designed to allow the production of high-definition, detailed parts and smooth surfaces that do not require manual finishing.

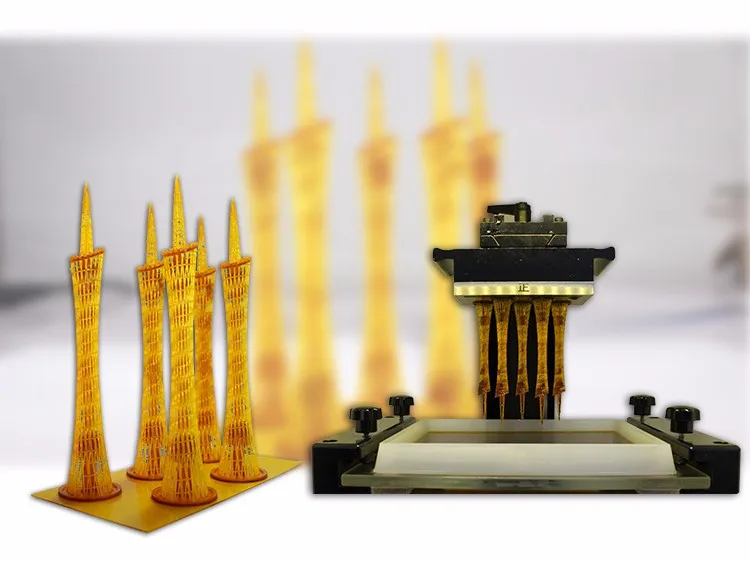

Jewelry Moldings , which can be successfully printed by our 3D printer, can be directly casted.

What's the differences between our 3D printers and other brand 3D printers?

1.Our DLP(digital light printer) 3D printer is special and just for Jewelry Industry as its high precision of reaching 0.01mm with high surface finish Resin moldings.And the LED light source service life can be 20000 hours.

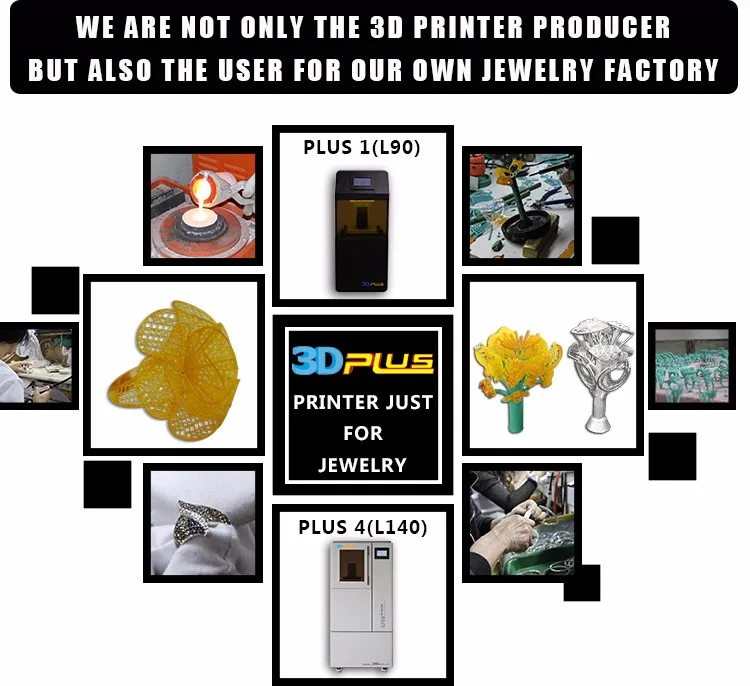

2.With Independent research, development and production as the manufactory of 3D printer, we has also played the role of user and put our 3D printers into use in our own Jewelry factory. We have an Jewelry factory with all process plants of Jewelry Making.

3. We have put our 3D printer into use in our factory's jewelry making process, that means we can train you to how to operate our 3D printers to print perfect jewelry moldings, and we also can train you to how to solve all the problems about the printing-finished moldings in casting process.So you never need to worry about the any issues about whether it can print perfect Resin Jewelry moldings or whether the Resin Modling can be successfully casted.

4. We provide 3D printing service , So we can provide you not only 3D printer, but also the Resin moldings, Brass/Silver Casting Moldings, and final finished products with high surface finish and great details finish. This service shows again our confidence in our 3D printers, and also give clients confidence of our 3D printers' use in their Jewelry making process.

5. Compared with one international Famous Brand "XXX", our 3D printer 's quality is almost the same as XXX's 3D printer, but our printing cost is much lower than XXX's, as their cost for 1 piece of Jewelry resin molding is 1-2 dollars, but our cost is only 0.5 RMB for one piece of Jewelry resin molding.

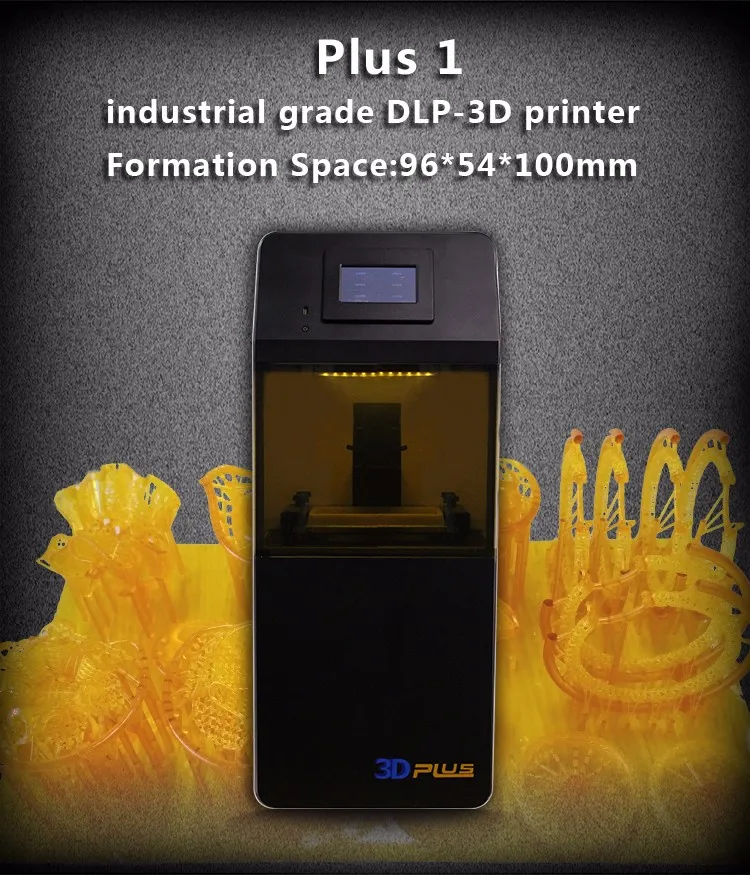

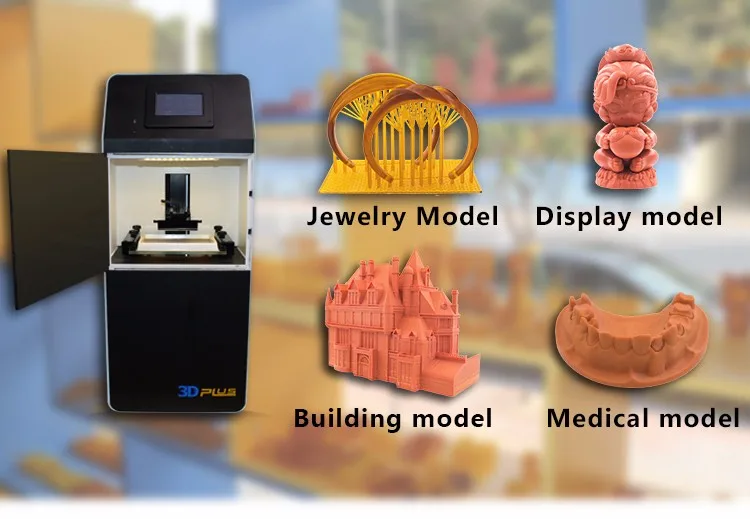

Product Description

Plus 1 is an industrial grade DLP-3D printer, which can print big-size moldings with high precision and great-smoothness surface quality. Very simple and easy operation, and it can assist small casting device to make jewelries in small batch and individuation.

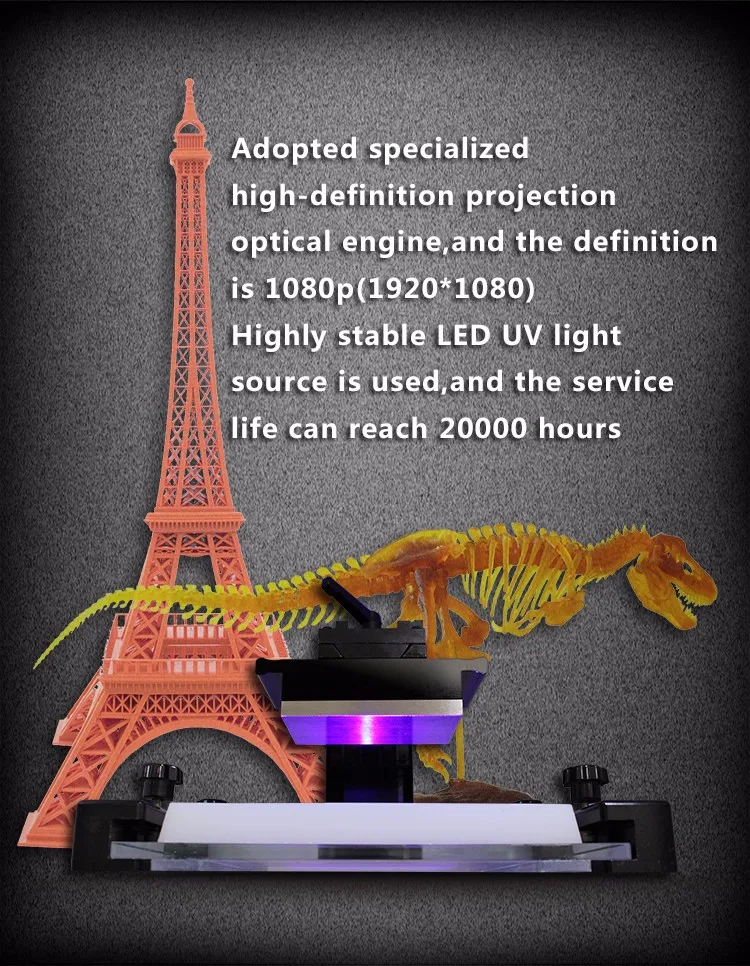

Plus 1 has adopted professional high-definition projection optical engine, and the definition is 1080p (1920×1080). It has high uniformity of illumination, which can ensure moldings to be formed stably at each position and site. Highly stable LED UV light source is used, and the service life can reach 20000 hours, to ensure reliable forming during the printing process.

2.Addvantages:

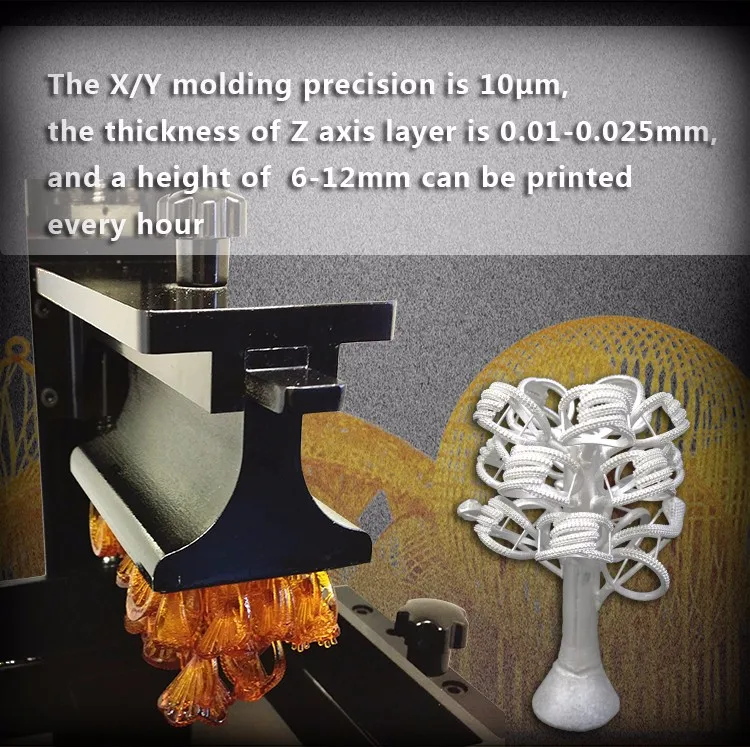

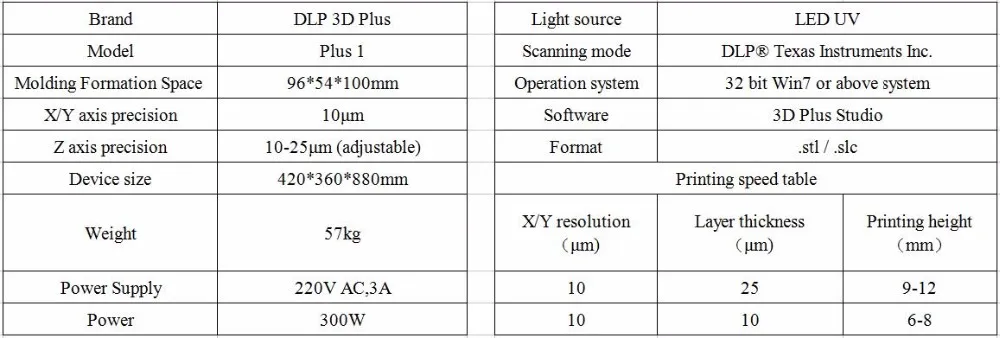

2.1 Scanning mode: DLP ,Manufacturing by Texas instruments INC USA ,it's Precision reach :±0.01

2.2 Light Source : LED UV ,service life can reach 20 000 Hours

2.3 High Defintion: 1080P(1920X1080)

2.4 X/Y axis precision:10μm Z axis precision:10-25 μm adjustable

2.5 Fine detail and smooth surface finishing

2.6 Variety of resins ranging in rigidity, detail, color, clarity and temperature tolerance

2.7 Capable of light-duty function and service as short-run low-temp tooling

2.8 Can be painted and finished for presentation, demonstration and photo reproduction

2.9 Functional parts produced within a few hours or a few working days depending on the size and complexity of the project.

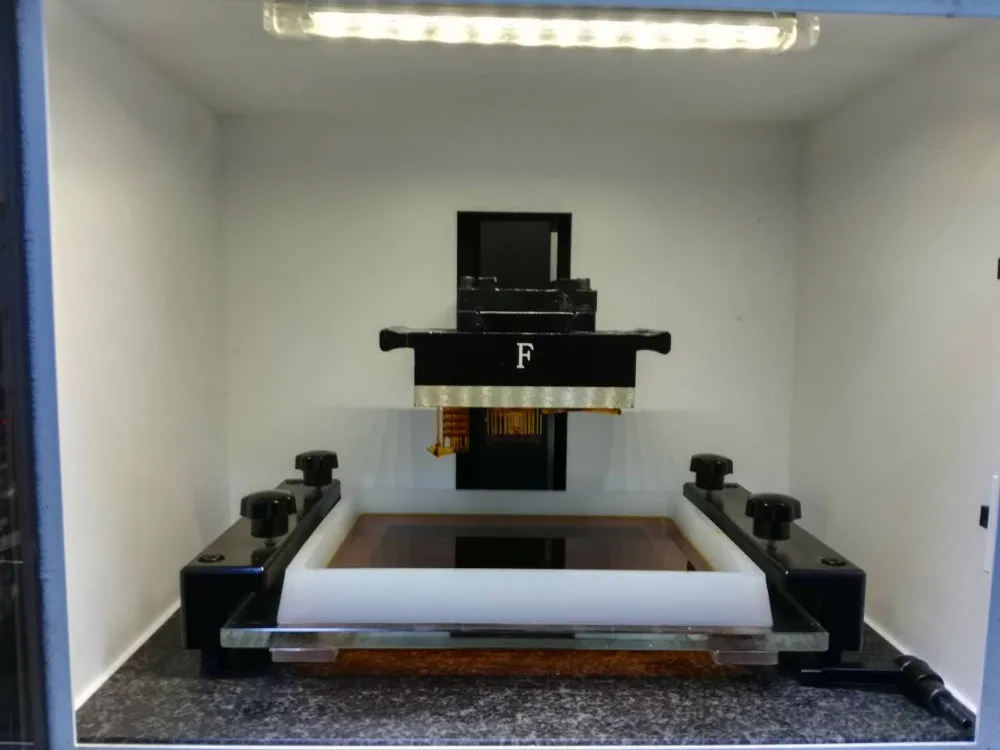

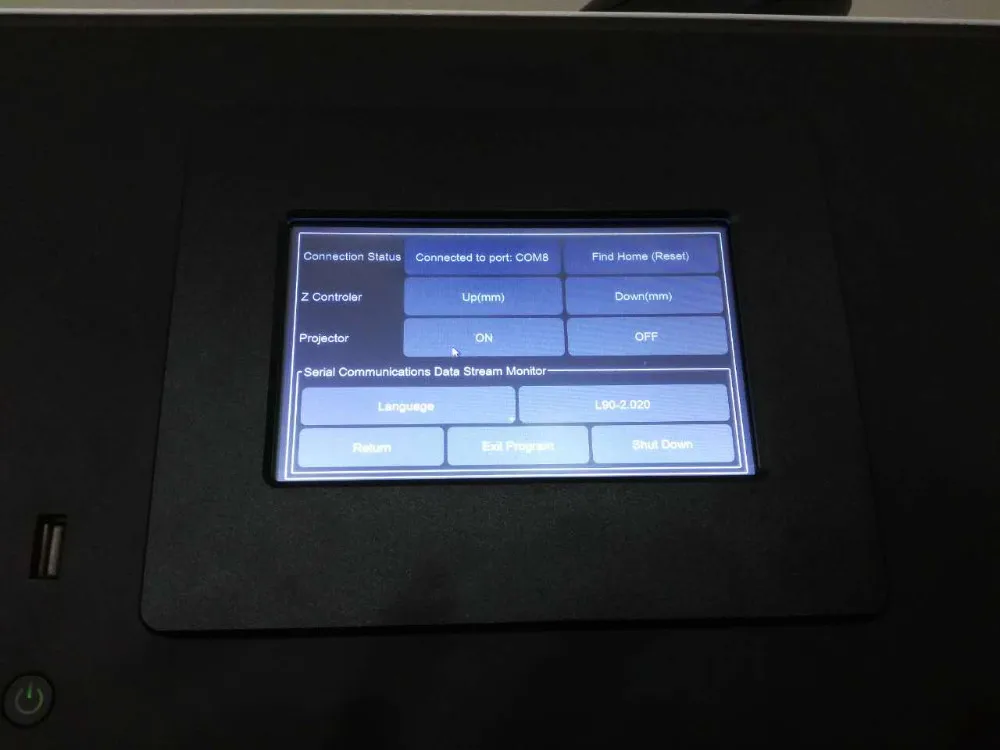

2.10 Marble working platform 2.11 Computer operating system platform

3.Application:

Detaileds:

Marble working platform:

LED Light Source:

Computer operating system platform :

3D Printing Molding Samples:

Our Service

Our Service

1. Pre-sale service

you can send your own Jewelry CAD drawing files to us by email, we will print and cast moldings for you free off charge, to test our pinter's precision and formation. We can take pictures to show you the moldings and also can send them to you.

2. In-sale service

We will provide you complete manual in word files and vedio files , to tell you how to operate and maintain our 3D plus printer step by step.

And also we accept your staff to come to our place for training.

3. After-sale service

We have English engineers to fly to your place for training your staff . And you can also find our after-sale service by telephone and internet in 24/7 .

4. Warranty

One year for whole machine except Material tray and Resin. Two years for LED light source.

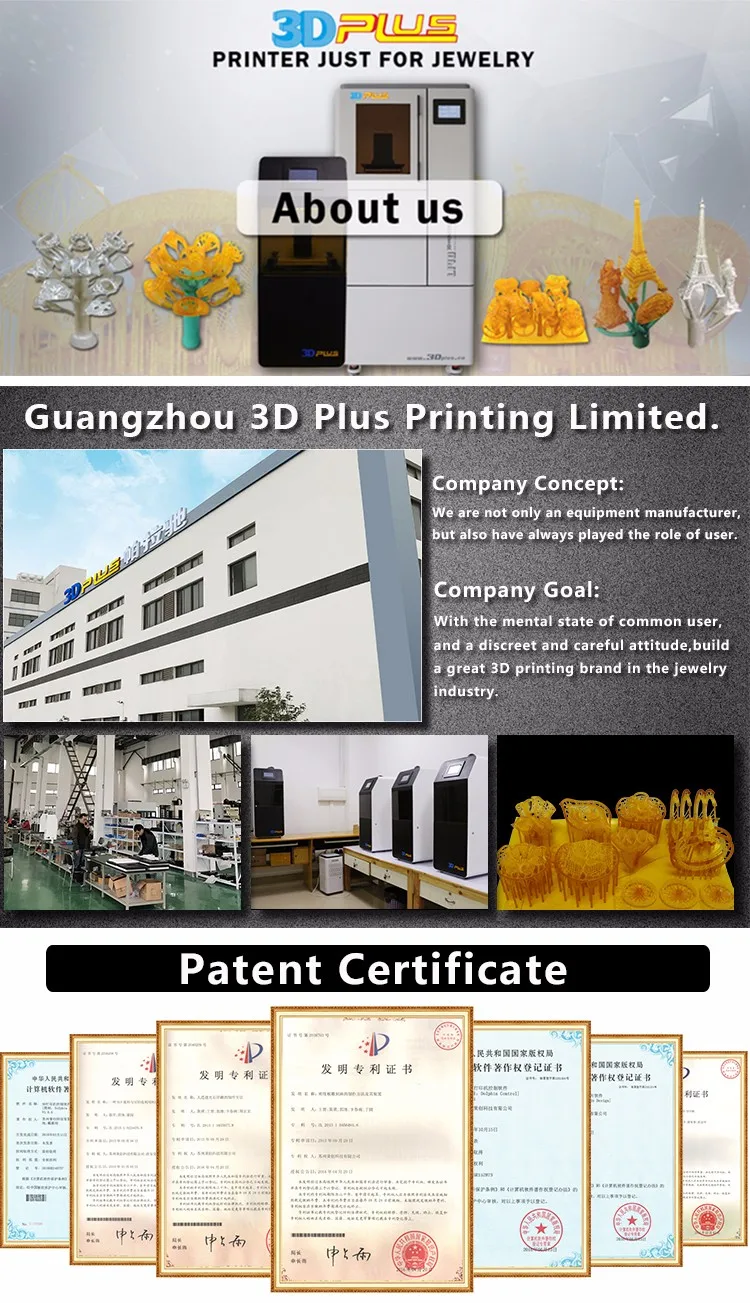

Company Profile

FAQ

why choose us?

A. We are a Professional 3D Resin Printer Manufactory with Newest Digital-light Printing 3D Resin Printer Special for Jewelry Industry.

B.Our 3D printer is special for Jewelry industry with its high precision 0.01mm, high surface smoothness, High Materail Ultilization almost 100%, Bigger Printing space and of course with high speed of printing 6-12mm per hour.

C.Our unique advantage is that our 3D printer uses highly stable LED UV light source, and the service life can reach 20000 hours; and our workbench material is marble, it can perfectly protect Z axles from shrinking move by thermal expansion or contraction. So it can keep high precision printing.

D.And it is perfectly suitable for Jewelry Making.

E. We have professional after-sale service team, we can send our English engineers to your place for training or solve your problems, and also we can train your staff in our factory and solve your problems in our place by telephone or internet as word files or vedio files.

Our Company's Concept is:

We are not only an equipment manufacturer, but also have always played the role of user.

So all your problems during your operating our 3D plus printer and Jewelry making can be solved at our own jewelry factory.

Tell us your problems, we will give you the solution in our own practical machine producing and jewelry making.