automatic fireresistant mgo slab forming equipment

The production line adopts the technology of double-drive double-roller extruding, and the product is formed once

after sizing, material feeding, spreading no-woven cloth, compounding and repressing. fireproof mgo board

production line runs stably with high automatic degree, the specification of its product can be adjusted arbitrarily.

The equipment actually realizes the industrial production line of new model building wall board, and the boards have even and glazed surface with high compactness.

The equipment largely reduces the labor intensity of worker and thoroughly changes many shortages of the former

casting forming with upright mould or flat mould, such as large mould usage, low recycling rate, required electrical

heating or steam heating, single kind of product as well as the sound insulation and heat-preserving which don’t

meet the market requirements.

Technology featuresThere is not any requirement about high temperature and high pressure during production processing. The board

will be formed at one time after roller-extruding under the conditions of normal temperature and normal pressure.

This is a green environmental-protection project, because that there is no waste water, waste materials and waste

gas during its production processing. The finished board don’t need high temperature drying, air-drying and

watering,and under the normal temperature, they will dry well indoor.

|

Advantages

|

||

|

Number

|

Item

|

Content

|

|

1

|

Low cost

|

Low labour and raw materials costs

|

|

2

|

Long life

|

Up to 30 years

|

|

3

|

Recycling use

|

Reused for more than 8 times

|

|

4

|

Environment protection

|

Environment-friendly raw materials used

|

|

5

|

Flexible layout

|

adjusted according to your requirement

|

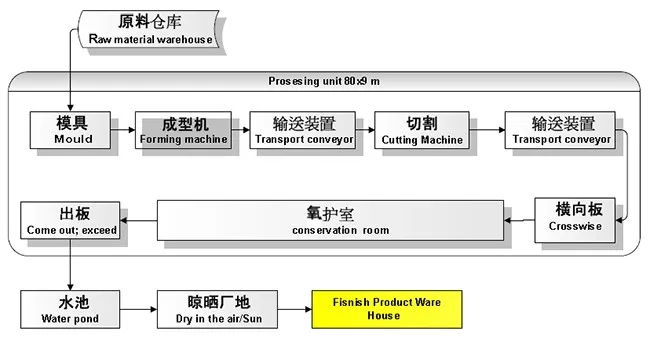

This automatic mgo board production line in China is made up of two parts, Board making machine line and Board four-sides cutting machine Line

Board Making machine Line

|

NO.

|

name

|

Function

|

Size (mm)

|

Power(KW)

|

Quantity(set)

|

|

1

|

Slurry mixer

|

Mixing cement mortar of up and own materials

|

2300×820×820

|

3

|

2

|

|

2

|

Main mixer

|

Mixing middle materials

|

2800×1500×1300

|

18.5

|

2

|

|

3

|

Crusher

|

Crush and collection material after cutting

|

1960×880×1070

|

11

|

1

|

|

4

|

Duplex units feed in mould board

|

Automatic feed-in mould board on the main formed units, no need by manual, can reduce labor, improve work speed.

|

4800×3100×2800

|

1.5

|

1

|

|

5

|

Main formed units

|

It includes all of device of automatic feed-in cement mortar, fiber cloth, spreading, one-time forming and etc.

|

29000×1800×1500

|

11.5

|

1

|

|

6

|

oil brusher

|

It can adhibit the PVC paper on the mould board by automatic. (Or brush the oil on the mould board)

|

2700×1600×800

|

1.1

|

1

|

|

7

|

Automatic tracking cutting device

|

It can cut the product on production line when it’s wet, and it will not hurt the product and mould board, reduce the labor, low labor intensity .

|

4500×2000×1450

|

2.45

|

1

|

|

8

|

Hydraulic lifter of receiving board system

|

It can load the formed board on the form rack, reduce labor, reduce hurting the board when by manual, and improve automatic.

|

2700×3800×1700

|

9.6

|

1

|

|

9

|

PLC Control system

|

Control the production line automatic.

|

750×500×1800

|

|

1

|

The production line is composed of board-making machine,glue-spreading and veneering-drying machine and

glazing machine.according to the production and the automatic degree, this production line is divided into 6

models and three specifications ,such as large ,middle and small specification.The production line for mgo board

has :production workshop ,finished product workshop and raw material warehouse . workshop:100---1000m2,

worker:3---6person,water:ordinary water,electricity:1.1—10KW(according to different scale)

1. The source of the production raw materials is widely with no regional restriction. The product is made of magnesia, mgcl2,fiber glass mesh, on-woven fabrics and other fillers. The board is formed one-time by the machine. It is easy operation, low production cost, small investment and fast effectiveness.

2. The automatic mgo board production line has high automatic degree, simple production technology, low labor intensity and production line is no noise and three wastes (waste water, waste gas and waste residue) during production.3. Low production energy consumption. With the influence of chemical reaction, it can meet the requirements about production technology without high temperature and high pressure. 4. It can produce according to different customers' request like size (length* width*thickness) , material .This automatic mgo board production line in China can produce boards Max length 3660mm and width is 1250mm. Thickness from 3-25mm.

1. Thickness: 2-24mm2. Width: 600mm-1300mm3. Length: 2400mm-3000mm 4. Capacity :200 -----2500 sheets per day 8 hours .5. Configuration :customization

|

frequency

|

pressure

|

equipment

|

rooms

|

capacity

|

|

50HZ

|

380V

|

1.7million M2

|

12M*80M/9M*40M

|

10KW-15KW

|

|

Item

|

Size

|

Thickness

|

weight

|

|

1

|

1220*2440mm

|

3mm

|

10kg

|

|

2

|

1220*2440mm

|

4mm

|

14kg

|

|

3

|

1220*2440mm

|

6mm

|

18kg

|

|

4

|

1220*2440mm

|

8mm

|

24k

|

|

5

|

1220*2440mm

|

10mm

|

28.5kg

|

|

6

|

1220*2440mm

|

12mm

|

34kg

|

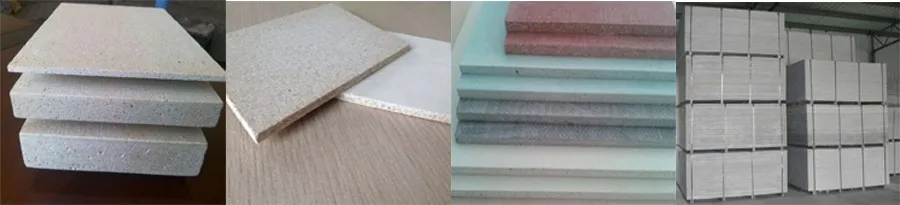

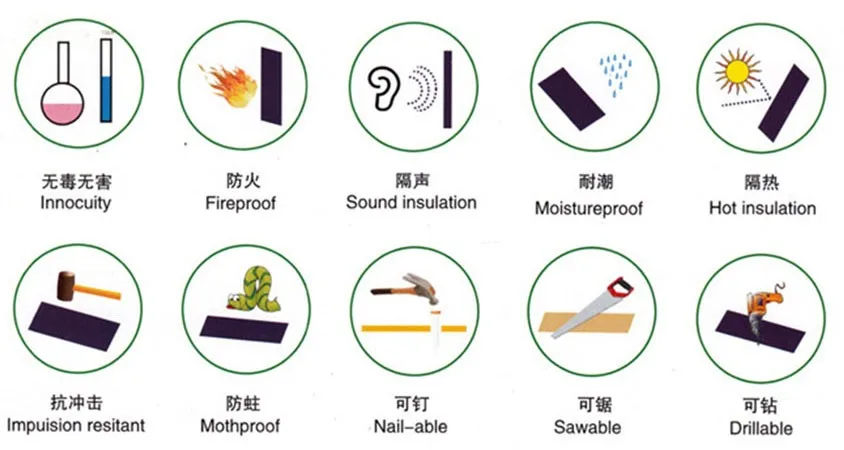

Features of mgo board:

1.Strong fireproofing capability2.Good shockproof capability3.Smooth and scratchproof face4.Good safety performance5.Superior performance in sound insulation and heat insulation6.Damp-proof and non-reaction with halogen7.Wide applicable scope

8.Bend-proof

MgO Board Machine mainly produces all kinds of magnesium oxide boards, they can be used for ceiling, wall skirting, decorating of indoor wall and lining board for furniture.It can replace three-ply board, five-ply board, flakeboard, MDF (Medium Density Fiberboard ) and Gypsum Board.

Technology index

|

Oxygenic index %

|

>90

|

|

Level combustion

|

SO

|

|

Vertical combustion

|

SO

|

|

Water content rate

|

10.9%

|

|

Capacity

|

1.15g/cm3

|

|

Static bending intentsity

|

169.46Mpa

|

|

Density

|

T/m3 1.13

|

Water resistance :Without chalking for 24 hours and there is no change on surfaceNo “Three-waste” (waste water ,waste gas ,waste residue),no pollution and environmental protection .

|

1. Full life-cycle value services:

|

Our company provides latest building materials/Magnesium oxide board production machine/Siemens PLC control automatic Mgo board production line, cost accounting, installation and operation, equipment maintenance and the whole life cycle technical all support.

|

|

2. All-around technical service:

|

We provide technical formula for clients, to help clients to occupy the leading position in the market.

|

|

3. Complete data specification:

|

Provide production line equipment technical data and instructions, and provide the Mgo board production line formula.

|

|

4. Quality commitment:

|

Our company regards product quality as the lives of enterprises, the main components and wearing parts are made of high quality.

|

|

5. Trade service:

|

We can help the customer to do the consignment and the relevant procedure for import and export.

|

Q1.What’s your advantage? Why we choose you?A:1)10 Years experience of test pen production and R&D.We have the most professional techniques and team. More advantage in price 2)Great production capacity Sustainable Supply . According to customer requirements, We support the customized. 3)The project is envoronmental protection.The main raw materials are from gricultural and industrial waste, such as crops straw, sawdust, fly ash, sand and etc. The products are absolutely ecological and low cost.Q2.What’s the Payment?A:T/T would be better with quick transfer and few bank fees. LC could also be accept, but the procedure is complex and the fee is high.Q3.Are you a factory or trading company?A:We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q4.How long is the warranty of your equipment?

A:1 Year.

Q5.Do you supply spare parts?

A:Excellent easy broken parts support for buyers. Easy broken parts guarantee for one year.

Q6.Will you provide training?

A:The training is free of charge , and our engineer will be on duty to train your worker.

Q7:How will you provide installation&commissioning?

A:Will provide 2~8persons(adjustable according to the degree of automatic )for installation.

Shandong Chuangxin Building Materials Machinery Co., Ltd., as a new and high technology enterprise registered at provincial industrial and commercial department and a modern group enterprise integrated with scientific research, processing and trade mainly focus on research, development and popularization of decorating technique, building materials technology and machinery. Its many patent products were sold throughout China and some were exported to Russia, Southeast Asia, Hong Kong and Taiwan. We have had rich assets and intellectual property rights after many years. The company is composed of Machinery Factory, Technology Development Center, Decorating Materials Factory, Handicraft Development Center and Research Institute of Paint and Coatings, and it establishes cooperative relationship with Higher Educational Institutions and Scientific Research Academy in Beijing and Shandong. With perfect scientific research production base, rich material conditions and technical force and acute market feeling, the company reformed boldly and strengthened exchange and cooperation with the world, and at the same time made its technology and equipment always meet requirements of changing market.