The Parameter of bga rework station :

| Place of Origin |

Guang dong , China |

| Brand Name | Wisdomshow |

|

Moed Number |

WDS-620 bga rework station |

| Superior function | Soldering and desoldering bga chipset |

| Power | AC 220V±10% 50/60Hz |

|

Total Power |

4800W |

|

Heater power |

upper temp.zone 800w, second temp.zone 1200w, IR teom.zone 2700w |

| Temperature Controlling | K-type thermocouple close-loop control,independent temp.controller, the precision can reach ±1℃ |

|

PCB size |

Max:370*380mm Min:10*10mm |

|

Applicable chip |

Max: 80*80mm Min 1x1mm |

| Thermocouple Ports | 1 units |

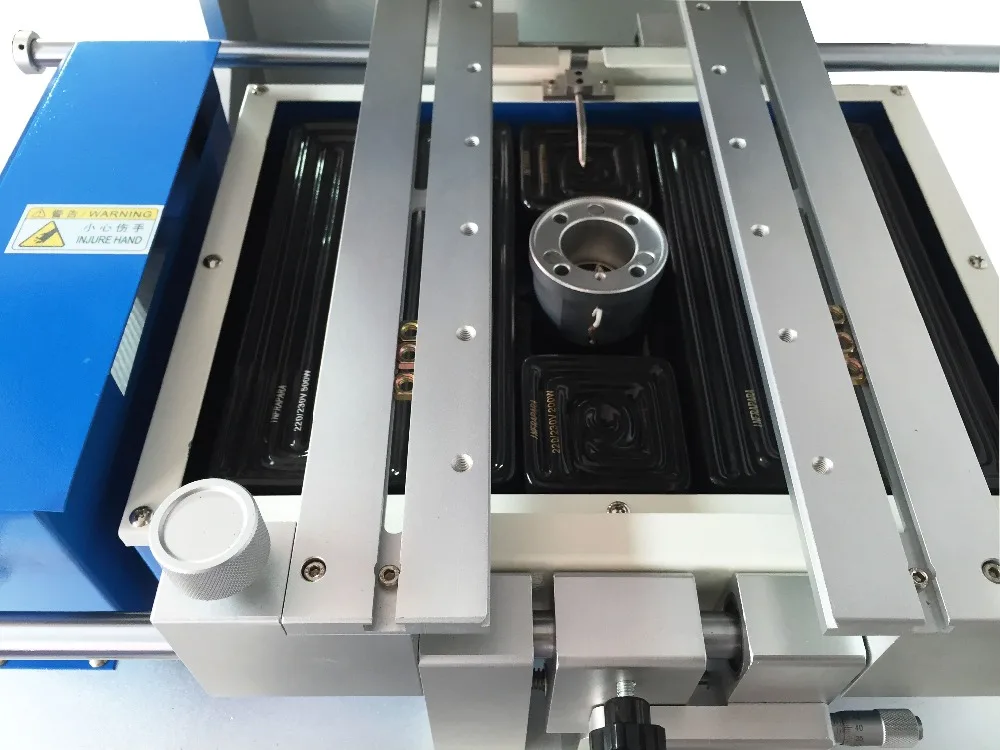

WDS-620 BGA Rework Station Detailed SHOW

Independent 3 heating zones temperature control system

Precision optical alignment system

Multi-functional and humanized operation system

1.Adopting the HD touch human-machine interface;upper heating head and mounting head designed 2 in 1;providing many kinds of titanium alloy BGA tuyere can be rotated in 360 degree for easy installation and replacement

2.X,Y and R angle adopted micrometer fine-tuning,accuracy locating,precision can reach ±0.01mm.

Superior safety protection function

With the alarm function, after the BGA welding the machine can alarm by itself.In the case of temperature abuse,

the circuit can power off automatically with the double over-temperature protection.Temperature parameter having password protection to prevent any modification. bga welding machine.

Packaging & Shipping

Packaging & Shipping

WDS-620 bga rework station package & shipping?

1,Standard export wooden package for bga rework station:83*70*87cm,105KG

2,Delivery in 2 workdays after payment confirm;

3,Shipping by TNT, UPS ,DHL,FEDEX (IE), Aramex or by air or by sea

4,Loading Port: Shenzhen or Hongkong

1.Your inquiry will be replied in 24 hours ;2.Offer free spare parts and service within one year of warranty,but all the other relative cost should be on the buyer's account;3.Technology Support :Provide Demo operation video for training ;If you have time,welcometo our company,will arrange engineers to show you the operation;4.Good and professional after-sales service;5.Give great discount to AGENCY to ensure agents profit.

Welcome to visit our factory !

What we can also supply:

We are professional BGA rework station manufacturer, commit to provide the one-stop service for customers.

So that we also supply the motherboard repair equipment(like soldering station, desoldering gun, etc) and BGA Reballing

tools(like solder ball, flux paste, solder wick, reballing kit, reballing stencils for laptop, ps3,xbox360, mobile, etc) FAQ

FAQ

1. This is the first time I use this kind of machine, Is it easy to operation?

There is english manual or guide video that show you hot to use machine . If you still have any question,please contact us by e-mail/skype/phone/trademanager online service.

2. If machine have any problem after I receive it, how can I do ?

Free parts send to you in machine warranty period.If the parts is less than 0.5kg,we pay it IF it exceeds 0.5kg, you need to pay the postage.

3. Hou can I buy this machine for you ? ( very easy and flexible)

A. Consult us about this product on line or by email

B.Negotiate and confirm the final price ,shipping ,payment methods and other terms.

C, Send you the proforma invoice and confirm your order.

D, Make the payment according to the method put on proforma invoice.

E. We prepard for your order in terms of the proforma invoice after confirming your full payment. and 100% quality check before shipping.

F. Send you order by air or by sea,

4. What is the payment way ?

We accept the payment terms: Bank transfer, Wester Union, Moneygram, Paypal, etc.

Some of Customers' voice :

1.Hi mate, your best price and high purity product is so competitive in my country , this let me make much profit , my customers are really like it . cooperate with you is so wonderful ! thank you ! ---------Richard---Turkey

2.i have received my products , your packing is do discreet and perfect , it really amazed me .i will order more from you as soon as possible. thanks a lot. -----------Robet--Australia

3.i have cooperated with you for many times , your product quality is so great , that is why i still buy the products from you . thank you . ------------- Corentin ---Brazil

Thank you for your interest. Any more detail pls contact as below