Jaw crushers are a primary crusher used in mining, construction, and demolition recycling. Jaw crushers are the work horse of the crushing industry. Fote jaw crushers are a ready-to-run solution, speeding up the deployment process and allowing you to focus on processing ore. Their reinforced design provides both tremendous longevity compared to other models, while maintaining low energy consumption.

When it comes to maintaining a jaw crusher and securing the most uptime possible, the key is to developAs with all crushers, the maintenance of a crusher depends on how it is applied and taking a proactive approach to maintenance items like wear parts. Replacing wear parts before they are worn out costs less and improves the PE jaw crusher’s performance, ultimately saving money, increasing uptime, and providing crusher longevity. a proactive preventive care program and become properly trained on the equipment.

http://www.orecrusherfactory.com/orecrusherpro/5-jaw-crusher.html

1. The PE1200*1500 jaw crusher has relatively large feeding size, so it has much stronger crushing capacity for large-block materials. This is too much for small-sized crushers to reach for.

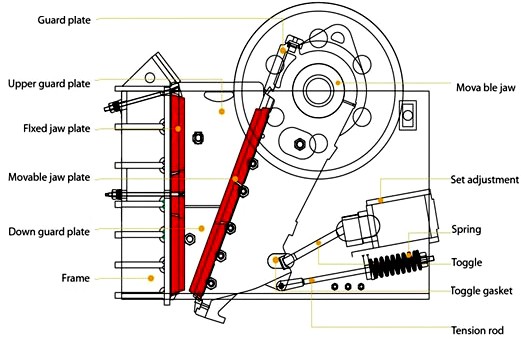

2. We use larger forging stocks to make the eccentric shaft, movable jaw plate and other parts, so the PE1200*1500 jaw crusher has much stronger bearing capacity and higher working stability.

3. Since the PE1200*1500 jaw crusher has low demands for feeding size, the crushing ratio can be extremely high. What’s more, PE1200*1500 jaw crusher can process raw material for many times, so the performance of finished products can be excellent.

http://www.orecrusherfactory.com/orecrusherpro/7-pe-600%C3%97900-jaw-crusher.html

Email: vip@sinoftm.com

Jaw crusher/Hard Stone Jaw Crusher/Highly Quality Jaw Crusher Machine