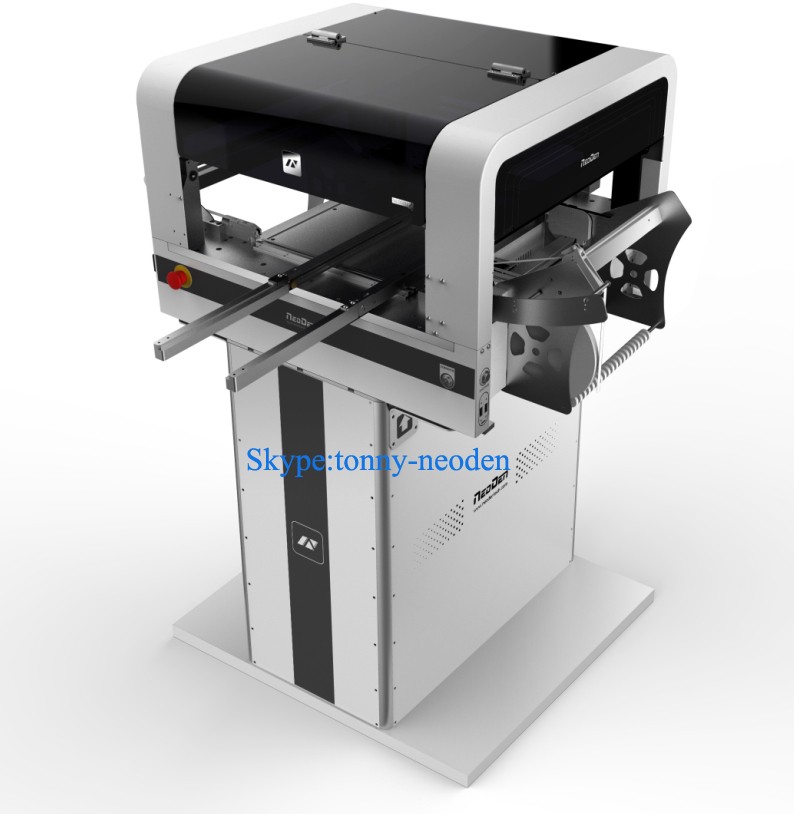

1. Dual vision system (up-looking and down-looking camers), identify and calibrate the different components at one

time, improves the accuracy of placement from 0201 to BGA;2. Auto rails, help to achieve continuous placement and solve the problem of long LED bar, ex. 1.2m LED strip;3. Automatic electric feeders, reduce the feeding deviation;4. General conveyor is supported, so a SMT production line can be setup, which is more time-saving and labor-saving5. Four placement heads can pick up and calibrate components at one time.6. The device supports remote system upgrade, NeoDen provides a life long system upgrade service for free to you;

Video:

https://www.youtube.com/channel/UCe5FjacDVT42MxKF2Q6Z9OQ/videos?view=0&sort=dd&shelf_id=0

1.Light weight body,occupy small area2.User friendly interface,no need professional SMT engineer,entry-level device3.High integrated,no need extra pump or any supporting facility4.High accuracy and reliability,make up the defection of manual work5.Low cost,reduce expense to own a professional automatic SMT production line6.International express with door to door service,3-5 working days delivery7.Especial for laboratory research and development,samples,to avoid any patents and designs revealment

Thank you very much for your support on Neoden Tech's machines.