Professional tube laser cutting equipment manufacturers, pipe cutting machine suppliers

GS-LFTC60 laser cutter is equipped with IPG laser generator as well as other efficient drive mechanism such as high precision gear rack, imported high precision linear guide rail, etc., and assembled through the advanced imported CNC system. It is a hi-tech product integrating laser cutting, precision machinery, CNC technology, etc. mainly used to cut and form carbon steel sheets, stainless steel sheets, aluminum alloys, composite materials, etc., with the features of high speed, high precision, high efficiency, high price performance ratio, etc. It is the first choice cutter model in the metallic material processing industry.

Performance Parameters of GS-LFTC60 CNC Laser Cutter

|

No. |

Performance Indicator Parameter |

|

|

1 |

Processing surface (L × W) |

6200mm×Ø20-180mm |

|

2 |

X axle stroke |

6750 mm |

|

3 |

Y axle stroke |

200 mm |

|

4 |

Z axle stroke |

160mm |

|

5 |

A, B, C Axis stroke |

Rotary Limitless |

|

6 |

X,Y,U Axis Max. Location Speed |

100m/min |

|

7 |

A, B, C Axis Max.Rotating Speed |

100rpm |

|

8 |

X,Y,U Axis Max.Acceleration |

1G |

|

9 |

X,Y,U Axis Location Accurracy |

±0.03mm/1000mm |

|

10 |

X,Y,U Axis Repeat Location Accurracy |

±0.05mm |

|

11 |

CNC System |

PA8000 |

|

12 |

Auto Loading Control System |

Siemens |

|

13 |

Max. Load of Worktable |

100KG |

|

14 |

Machine Tool Weight |

10T |

|

15 |

Loading Length |

2500-6200 mm |

|

16 |

Unloading Length |

0-4000mm |

|

17 |

Phase/Power/Frequency |

3/380V/60Hz |

|

18 |

IP degree |

IP54 |

|

19 |

Dimension(L*W*H) |

13000*4500*3000mm |

Advanced Control Function:

1. Sheet material surface height tracking control (follow-up function):The Z axle allows sheet material surface height tracking control to adapt to different evenness of sheet materials. The function is integrated in the CNC system, and provides quicker response, better sensitivity and higher servo precision compared to conventional CNC system.2. Laser power ramp control:During acceleration and deceleration of the CNC laser cutter, PA8000 CNC system can adjust the laser power ramp according to the real time speed of the CNC laser cutter to ensure consistent quality of processing section. The function is also integrated in the CNC system, and provides quicker response and better instantaneity compared to conventional CNC system.3. Self-adaptive feed forward “ART” regulation technology:The self-adaptive feed forward “ART” regulation technology allows the PA8000 CNC system to make self-adaptive regulation during motion control on real time basis. The CNC laser cutter position control closed loop can reach the optimal gain and the best rigidity. The “zerolag” feature of “ART” regulation technology makes the CNC laser cutter has the minimum servo lag error and the highest position servo accuracy.4. Rollback function:If the laser cutting stops due to failure, the machine can cut the work piece previously being cut again after returning along the outline path of the work piece to prevent scraping the work piece.5. Breakpoint return function: If the laser cutting stops due to failure, the X, Y and Z motion axles can be moved; the cutting nozzle is repaired or replaced; the machine is returned to the breakpoint and restarted to begin cutting to prevent scraping the work piece.

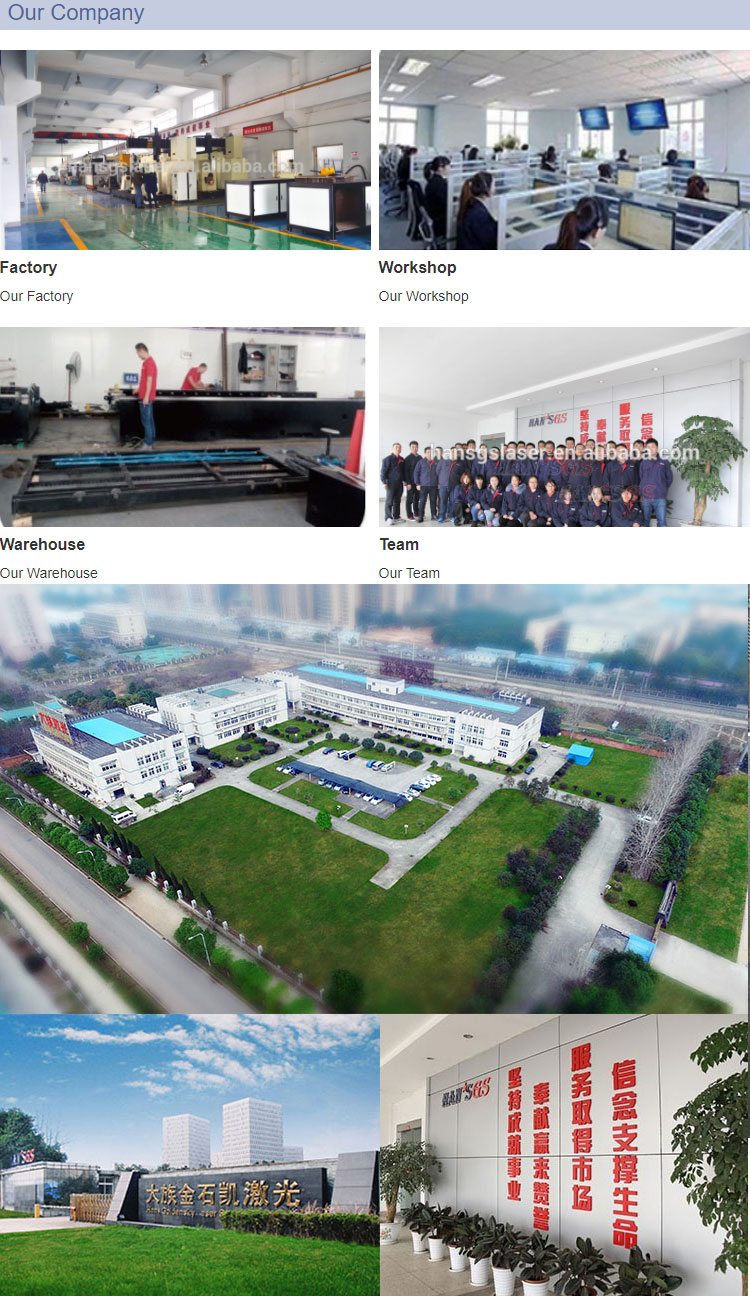

Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans.

Company has been successively undertaken the national development and reform commission (NDRC) national high-tech industrialization demonstration projects, the top ten key projects in Hubei province, Wuhan city top ten industrial projects of science and technology, and other government science and technology projects, including three products listed as a key project of national torch plan by the national ministry of science and technology. We successively obtains the national innovation fund, the electronic information industry development fund and a number of special fund support of Hubei province and Wuhan city, to be listed as the key innovation enterprise in east lake development zone, the key support leading enterprise in “large-scale laser equipment system integration and the new type laser manufacturing field" in Wuhan’s 11th five-year plan.

After-Sale Service

Our after-sale network is all over the world which will provide the comprehensive after-sale service to our customer.

Our commitment is as follow:

One year guarantee for the whole equipment.

We will answer your questions within 24hours.

When Equipment warranty expires, lifelong maintenance services will be provided.

After the expiry of the warranty we will offer a wide range of software support with free upgrade for lifelong .