Project introduction:

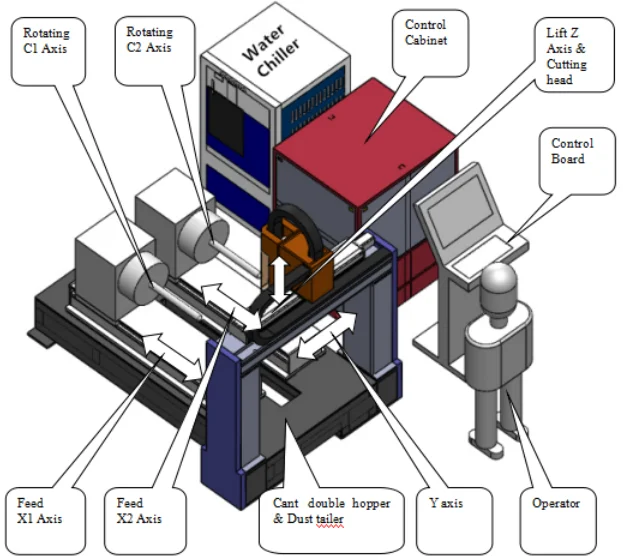

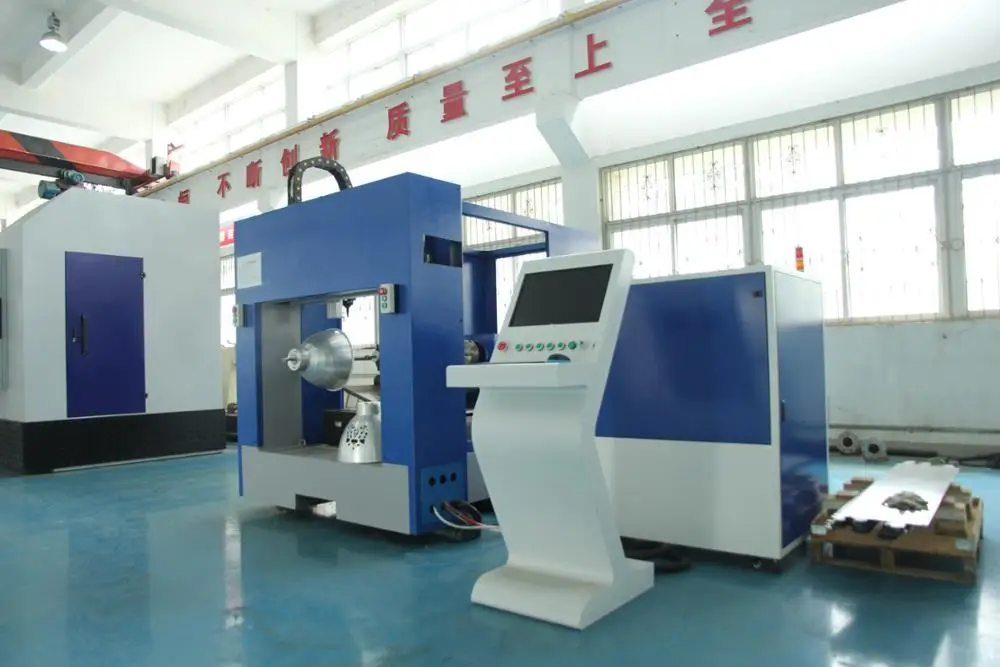

The cutting machine is the duplex mode, the operator stands as the below picture shows, X1 axis & X2 axis can be alternately cut and refueling, which can greatly improve the efficiency. After X1 axis completed the cutting, workpiece will be transmitted to the operator of X1 axis, the operator can up & down materials at the same time, then X2 axis deliver the workpiece to under the cutting head to cut; After X2 axis completed the cutting, workpiece will be transmitted to the operator of X2 axis for loading & unloading materials, then X1 axis deliver the workpiece to under the cutting head to cut, alternate each other like this. It ensures maximum utilization of the laser, has remained substantially cut, greatly enhance the cutting efficiency.

Specifications

| NO. | ITEM | SPECIFICATIONS | REMARK |

| 1 | Machine bed | GS-LFS1010 | Han’s GS |

| 2 | Laser source | IPG 500W/700W/1000W | United States |

| 3 | CNC control system | German Beckhoof | |

| 4 | Operating system | United States AheadTechs | |

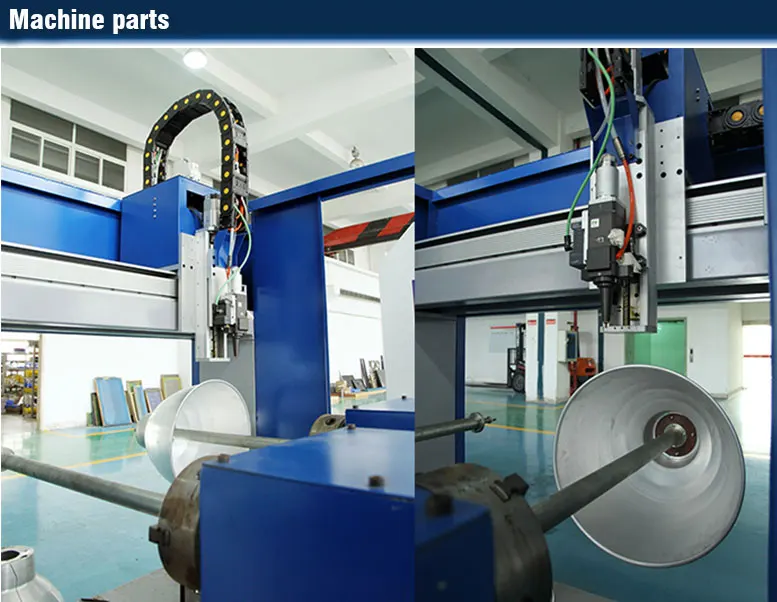

| 5 | Z axis servo system | Switzerland RayTools | |

| 6 | Laser cutting head | Switzerland RayTools | |

| 7 | Nesting software | UK radan | |

| 8 | Servo motor and drive | Japan Panasonic AC servo motor and drive |

X1axis:2.0KW; X1axis:2.0KW; Y axis:0.75KW; Z axis:400W with brake C1axis:1.5KW C1axis:1.5KW |

| 9 | Precision planetary gear reducer | GPX142 i=25 | |

| 10 | Precision linear guide & screw | HIWIN | |

| 11 | Control cabinet & operation board | Han’s GS | |

| 12 | Temperature and humidity adjusting machine | 250W | TONGFEI refrigeration |

| 13 | Cooling system | HC025M | HAN’S refrigeration |

| 14 | Voltage Stabilized supply | 20KVA | Shanghai |

| 15 | Display | 19” (Equipped with wireless mouse) | |

| 16 | Lubrication system | Motion axis lubrication | |

| 17 | Maximum cutting workpiece | φ500X800(Length)mm |

Advanced laser CNC machine

1. Laser cutting is one kind of modern cutting techniques, the best advantages of laser cutting is: small thermal deformation, high cutting precision , little noise , pollution free, easy to implement automatic cutting, although the initial investment, the processing costs less than the machining 50%. Laser cutting as a state-of-the-art manufacturing technology, has a wide range of applications, flexible technology, high precision machining, quality,production process clean and easy automation, flexible, intelligent, and improve product quality, labor productivityadvantages.

2. Fiber lasers in recent years, the laser field is extremely concerned about the hot spots, quickly replacing the traditional YAG fiber laser processing field , the trend of the CO2 laser . It is widely believed that the power fiber lasers will be the third generation of the most advanced industrial processing laser. The fiber laser has many unique advantages : Beam quality, small size, light weight, maintenance free and easy operation pieces. Wind cooling, low running costs, can be used in industrial environments. Long life, high precision machining speed,energy conversion efficiency is high , you can achieve the intelligent , automation, flexible operation . From the perspective of the development of laser technology , fiber laser represents the direction and trend of the development of the laser , has important applications in the industrial, defense and other fields.

Working principle:

The cutting machine is the duplex mode, the operator stands as the below picture shows, X1 axis & X2 axis can be alternately cut and refueling, which can greatly improve the efficiency. After X1 axis completed the cutting, workpiece will be transmitted to the operator of X1 axis, the operator can up & down materials at the same time, then X2 axis deliver the workpiece to under the cutting head to cut; After X2 axis completed the cutting, workpiece will be transmitted to the operator of X2 axis for loading & unloading materials, then X1 axis deliver the workpiece to under the cutting head to cut, alternate each other like this. It ensures maximum utilization of the laser, has remained substantially cut, greatly enhance the cutting efficiency.

About Han’s GS

Wuhan Han’s Goldensky Laser System Co., Ltd. Was founded in 1998. We are subsidiary company of Han’s Laser (stock:002008). For nearly 20 years, Han’s GS specialized in R&D of laser equipment, including high power CO2 laser source for laser welding and laser heat treatment technique, laser welding machines, laser heat treatment machines, laser cladding machines, laser drilling machines, laser cutting machine, tec.

For 20 years, with the best quality and best service, Han’s GS laser machines has already covered all Chinese market and also very popular in America,West Europe,South Asian,East Asian etc. More than 80 countries. Han’s GS lasers will try our best to serve for you suitable laser solutions. Welcome you to join Han’s GS family,share top laser products and services together with word-wide customers.