1. GeneralTYPE CBGD marine explosion-proof or high efficiency low noise centrifugal fans are explosion-proof products for marine use which developed from the CGDL series marine centrifugal fans. The series are designed and manufactured according to, and ship regulations of Chinese and international.

Non-sparking fans are suitable for every cabin air ventilating and exchanging on ships which containing combustible and explosive gas. They are also applicable in other places that suit.

This series fans have been examined and proved up to standard by the Explosion-proof inspection Authority of the PRC and have got the certificate of inspection. They have also been examined by the Register of Shipping of PRC and have got the certificate.

2. Features This series, non-sparking fans have the features of high explosion-proof grade, high efficiency, low noise, no overload, well anticorrosive, resistance to swing vibration and shock, stable turning and safely, reliability, etc.

3. Structure

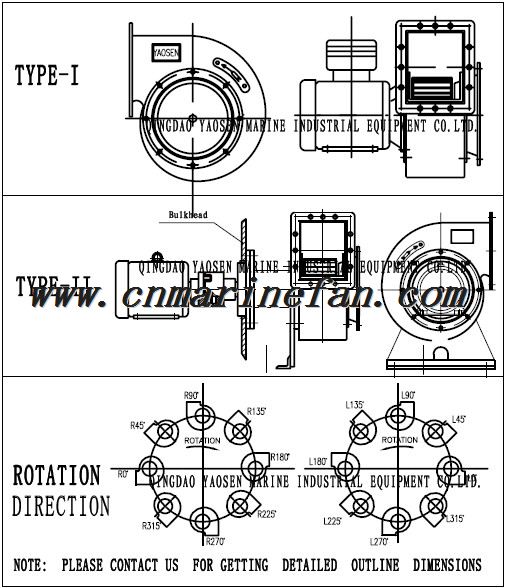

There are two structural types:

Type I (direct-coupling type) and type II (separate cabins type). The construction is non-sparking. The structure of type I is a motor direct coupling one, the impeller is mounted directly on the motor shaft, and the casing is fixed on the flange of the explosion-proof motor.The type II is a separate structure, the fan and the motor are put into different cabins, with a driving device, flexible couplings, and the driving device and the other side will be mounted on the bulkhead.

consists of bearings, bearing-box, shaft, brass rings, stuffing box, it can be oiled and measured the temperature. One side is fixed on the fan,

The fan may be made into a horizontal or vertical, single-stage, single-drawing and airtight structure by the customer’s requirement.

4. Model Explanation

4. Model Explanation

5. Use and maintenance5.1 Before installing the fans, should check whether each part is intact, whether the components are complete, whether the impeller and casing rotating direct are concordant.

5.2The air enter the fan from axial direction and come out through the impeller. It can be used for left or right rotation.

5.3When installing the duct of the inlet and outlet, should make the duct and fans be spontaneous identical, not join them forcing, not bring the weight of duct on the fans.

5.4After installed the fans, check whether there is friction of collide between the impeller and the fixed parts by rotating the impeller. If collision, friction, loud noise or strong vibration happened, the fan should be restart after checking. Avoid the fan being bumped and other substance or liquid entered the fans. Please clean the dust on blade of impeller in time, so as not to break the balance and strengthen the noise.

5.5The fans should be start-up without load. Before the fans started, should close the inlet or the adjust fittings. After operating, start to turn on it until to the formulary work state.

5.6The impeller’s rotating direct and the direct of the arrow should be concordant.

5.7After the fans wiring, the terminal box should be sealed, avoid the air or water in it.

5.8As the fans operating, the motor electric current should be control strictly, not exceed the rated electric current. Avoid the motor burning,

5.9The fans maintain must be done on stop working time. When burning, after check, should whether the every part of fans is normal.

5.10As some fault occurred in fans operating, should find out the reason in time and think a way of resolution.

We could Design and Produce the Marine fan,Industrial Fan,and Other Ventilation Equipment according to your detailed requirement !