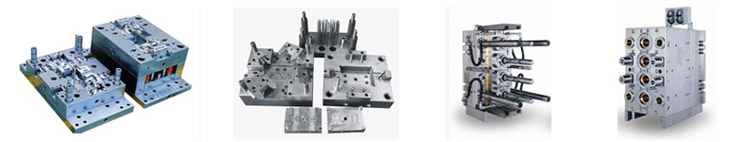

Plastic injection mould

000

Shenzhen sunnymold&plastic product Co., Ltd is a set of product development, design, mold manufacturing, injection molding, injection silk train service owned enterprises. We specialize in all kinds of precision mold design, manufacturing, precision plastic molding, etc., and a variety of independent research and household products, and won a number of national patents. The company has been ISO9001: 2008 quality management system standard operation, products are exported to Europe, America and other countries.

Company's existing plant area of over 10,000 square meters, has a variety of imported equipment more than one, in which the British imported high-speed scanner machine, high-speed precision CNC machining center 3 sets, 5 sets of imported CNC machining centers, EDM machine 10, High precision mirror EDM spark machine 4, line cutting 8, gongs bed 25 units, and other ancillary equipment more than one molding, injection molding workshop with Hong Kong Dahua, Toshiba and Canada HVSKY other world-class companies manufacture various types of injection molding machine 25. Also equipped with projectors, coordinate measuring instrument and other precision measuring instruments, precision molds to meet the requirements, the company has more than 20 senior engineers, over the years the company with technical skills, advanced equipment, good service, timely delivery, and win old and new customers. Plastic base mould Plastic containers moulds Plastic battery mould

The company has excellent team of technical personnel and advanced technology and equipment, the birth of each product are given the strength of our team and innovative spirit, with rigorous attitude, focus on excellence for customers to design the perfect product. Plastic base mould Plastic containers moulds Plastic battery mould

_____ Plastic base mould Plastic containers moulds Plastic battery mould

|

Product Name |

Plastic base mould Plastic containers moulds Plastic battery mould |

|

Mould Type |

Injection mould, die casting mould, Precision mold design and Plastic mold manufacturing |

|

Mould steel |

P20,H13,718H,2738,SKD61,NAK80,8407,S136H,etc |

|

Plastic material |

ABS,PC,PE,PP,HDPE,PPR,PVC,PBT,PS,PET,etc |

|

Mould base |

LKM,HASCO,etc |

|

Mould runner |

Cold runner and Hot runner,etc |

|

Mould Hot runner |

DME,HASCO,YUDO,etc |

|

Mould cold runner |

Point way,side way,follow way,direct gate way,etc |

|

Mould standard parts |

DME,HASCO,etc |

|

Mould life |

>500.000 shots |

|

Design sofeware |

Solidworks,UG,PRO-E,CAD,etc |

|

Mould doff way |

Doff plate,ejectors,air valves,hydraulic jar,etc |

|

Mould hot treatment |

Including quencher,nitridation,tempering,etc |

|

Mould cooling system |

Water cooling or Beryllium bronze colling,etc |

|

Surface treatment |

Paint,Texture,polish,print,anodize,electroplating,electroforming |

|

Hardness of the steel |

20-60HRC |

|

Equipment |

High speed CNC,standard CNC,EDM,Wire Cutting,Grinder,Plastic Injection Molding Machine,etc |

|

Mould packing |

Wooden case

|

000

0

8

888

888

8