Perforated metal, also known as perforated sheet, plate, or screen, is a versatile material with patterns of holes, slots, or decorative shapes achieved through manual or mechanical stamping or punching processes. It is made from diverse materials including stainless steel, cold-rolled steel, galvanized steel, aluminum, and other metals.

Specifications

Hole Patterns

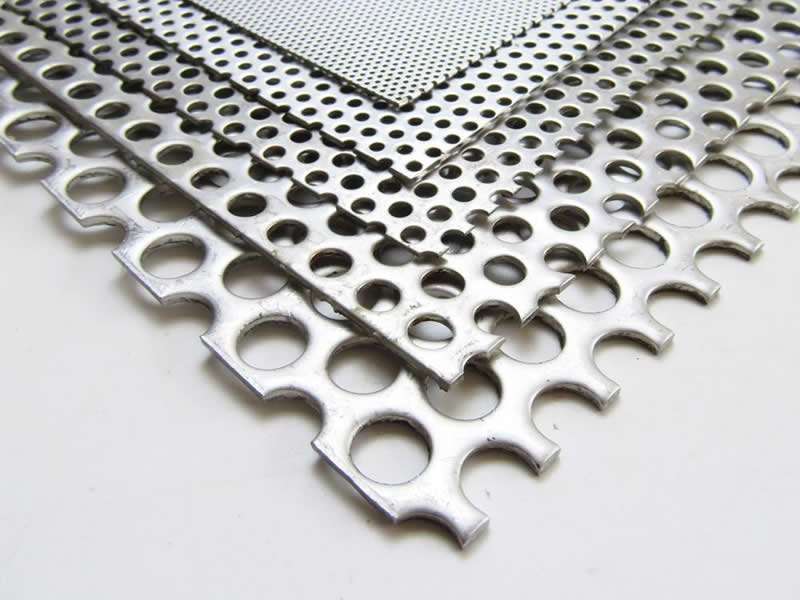

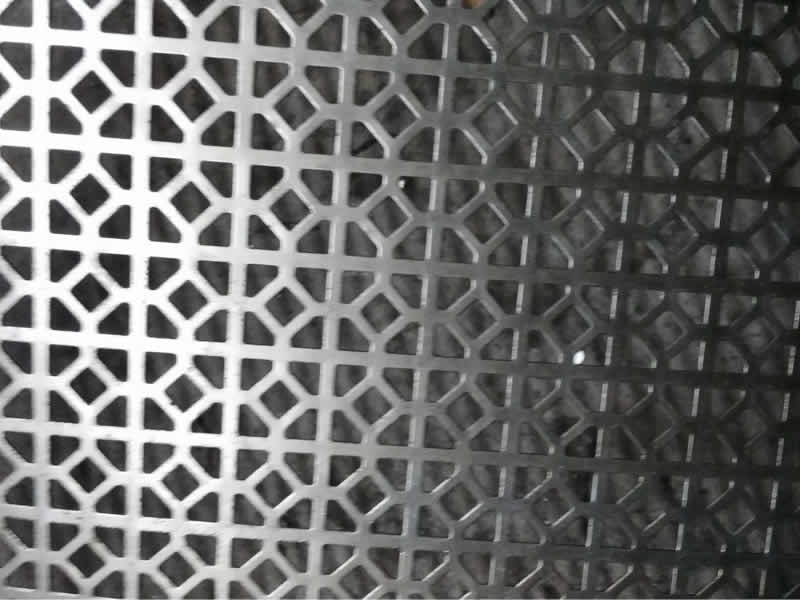

Perforated metal is available in a range of hole patterns, each designed for specific uses and aesthetic preferences:

- Round Hole Pattern: The most common pattern, suitable for a variety of applications. It provides good ventilation and is visually appealing. Typical hole sizes range from 1mm to 100mm.

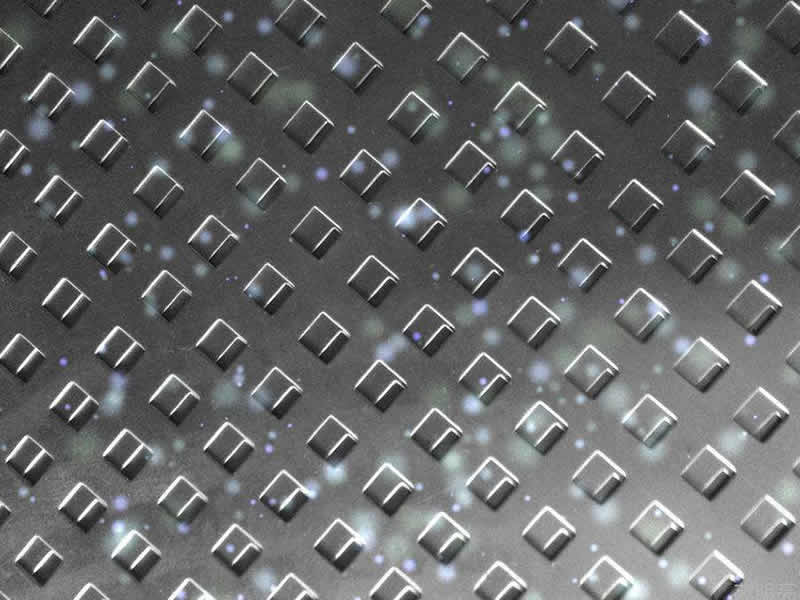

- Square Hole Pattern: Offers a uniform look and is often used for architectural and protective screens. Standard hole sizes range from 3mm to 75mm.

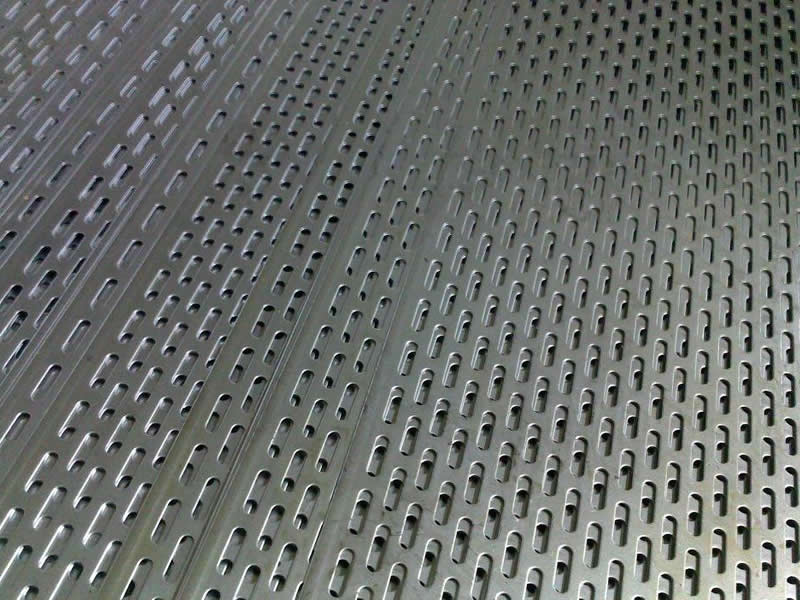

- Slotted Hole Pattern: Features elongated openings ideal for screening and sorting applications. Common sizes vary from 10mm x 20mm to 20mm x 100mm.

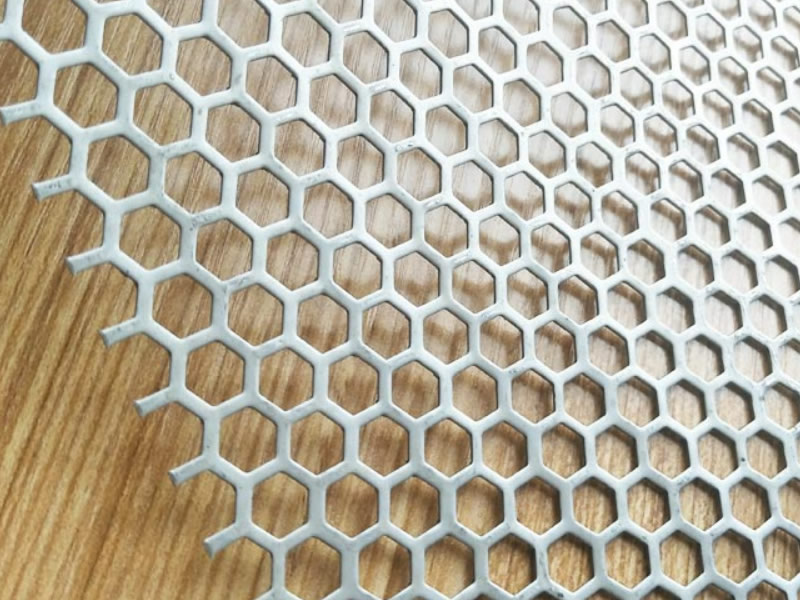

- Hexagonal Hole Pattern: These six-sided holes are used for applications needing efficient passage of air or fluids and are common in decorative applications. Sizes are typically from 6mm upwards.

- Decorative Hole Pattern: Customized to include various artistic and intricate designs suitable for aesthetic purposes in architectural projects. Sizes and shapes are designed to specific requirements.

Materials

Perforated metal is crafted from several different materials, each chosen for specific properties and applications.

- Carbon Steel: Commonly used for its strength and affordability, ideal for industrial and structural applications. Available in thicknesses from 0.4mm to 6mm.

- Stainless Steel (Grades 302, 304, 304L, 316, 316L): Offers excellent corrosion resistance and durability, used in environments prone to corrosion. Sheet thicknesses range from 0.5mm to 6mm.

- Aluminum: Known for being lightweight and corrosion-resistant, used primarily in architectural and decorative projects. Thicknesses typically vary from 0.5mm to 4mm.

- Copper and Brass: Valued for their aesthetic qualities and antimicrobial properties, these metals are often used in decorative applications. Available in thicknesses from 0.5mm to 4mm.

- Galvanized Steel (Pre-galvanized, Hot or Cold Galvanized): Provides enhanced corrosion resistance, suitable for outdoor use. Thicknesses for these materials range from 0.5mm to 3mm.

Surface Treatments

Perforated metal undergoes various surface treatments to enhance its durability, appearance, and functionality.

- Electro Galvanized: Applies a thin zinc coating through an electrochemical process, offering mild corrosion resistance for indoor use. Coating thickness is typically between 5 to 25 microns.

- Hot-Dipped Galvanized: Immerses the metal in molten zinc for a thicker coating, providing strong corrosion resistance suitable for outdoor environments. Zinc layers range from 45 to 100 microns.

- PVC Coated: Covers the metal with a layer of PVC to enhance corrosion resistance and provide color options. This coating is about 100 to 400 microns thick, adding smoothness and safety.

- Powder Coating: A dry powder is applied and then cured under heat to create a hard finish in various colors, ideal for both protection and aesthetics. Typical thickness ranges from 60 to 120 microns.

- Oxidation Treatment (Anodizing): Used primarily for aluminum, enhancing its corrosion and wear resistance. Oxide layer thickness is generally around 5 to 25 microns.

Click enlarge Image

Click enlarge Image