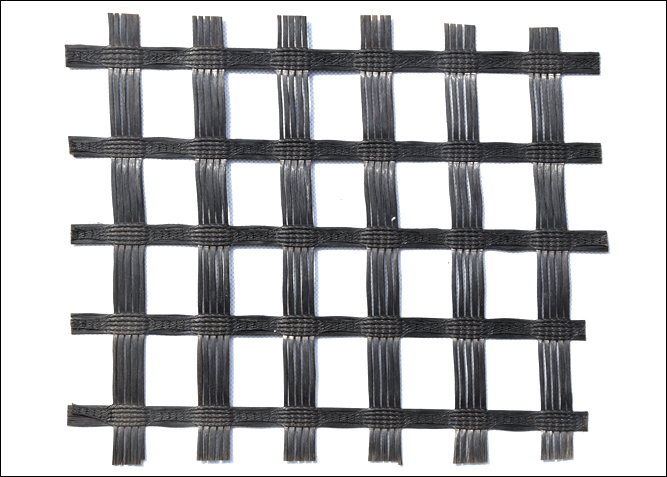

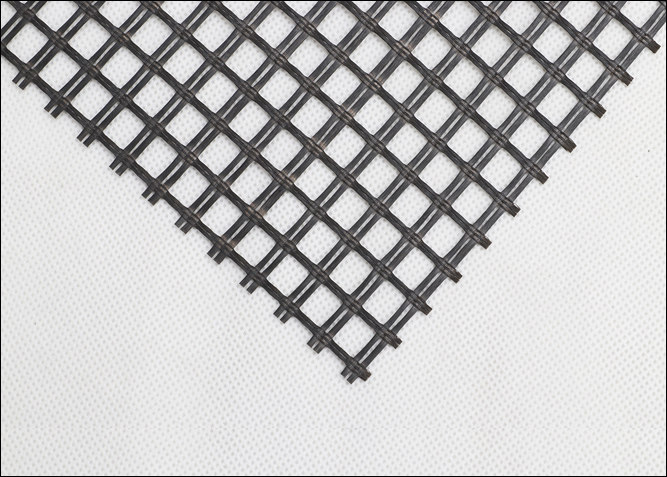

Fiberglass geogrid is an excellent geosynthetic material for asphalt pavement reinforcement and road base strengthening. This type of goegrid is a semi-rigid mesh product with high tensile strength and low elongation in both warp and weft directions, and it has excellent properties such as high temperature resistance and aging resistance. It is widely used for asphalt pavement, cement pavement and road base reinforcement, railroad road base, dam slope protection, airport runway, sand control, and other engineering projects.

This allows it to be used, and rutting, which ultimately solves the issue of asphalt pavement being difficult to strengthen.

Fiberglass geogrid to use in paving overlay to strengthen road surfaces, resist cracks

Specification: Fiber glass geogrid,100 kN/m,300 C fusion point

Fiberglass grogrid is laid over concrete roadway crack, then over lay with 2 to 3 inches of asphalt.

Fiberglass geogrid-4x4mm or 5x5mm geogrid fiberglass fabric without adhesive to put into an epoxy matrix.

Fiberglass Geogrid Mattress for construction project in a bituminous concrete parking area

Customized specifications

1) Fiberglass Geogrid with asphalt coated 40kn x 40kn

2)Fiberglass Biaxial Geogrid of min. 80 KN.m tensile strength, used as a reinforcement layer in asphalt road pavement.

3)Fibra de vidrio Geogrid/tela del geotextil, geogrid fiber glass mat with asphalt.

4)Fiber glass geogrid with tensile strength ≥ 50 kn for use in Panama.

Fiberglass geogrid netting specially for asphalt pavement mesh

What is the advantages of using fiberglass geogrid in paving roads?

Fiberglass geogrid features increased strength, excellent durability, improved load bearing capacity, superior weed suppression, and improved drainage.

In terms of strength, fiberglass geogrids are highly resistant to tension and strain due to their strong interlocking glass fibers. This makes them an ideal choice for reinforcing pavement layers, such as asphalt and concrete. The increased strength provided by fiberglass geogrid can help prevent cracking, rutting, and other types of damage that weaken pavement over time.

Fiberglass geogrid also has excellent durability. Unlike some other materials, fiberglass is able to resist the effects of UV radiation, extreme temperatures, dirt, water, and other sources of wear and tear. This makes it well suited for use in areas with extreme climates or environments. For example, the moisture and salt content in coastal areas can cause other materials to prematurely degrade. Fiberglass geogrid is not affected by these environmental factors and can last for many years, making it an economical choice.

In terms of load bearing capacity, fiberglass geogrids are designed to disperse weight evenly throughout the entire pavement system. This reduces pressure on any one spot and allows for thicker pavement layers while still providing support and stability. As a result, roads constructed with fiberglass geogrid can handle heavier loads without significant degradation over time.

Fiberglass geogrids also provide superior weed suppression. In any pavement system, weeds and grass can easily take root and grow between cracks and joints. Fiberglass geogrids act as a barrier that prevents the growth of weeds while allowing water to move through the soil. This helps reduce maintenance costs because it eliminates the need to regularly remove weeds from the road surface.

Fiberglass geogrids enable improved drainage. This is especially beneficial in areas where there is significant rainfall or runoff. The strong interlocking networks of glass fibers prevent water from puddling on the road surface and allow it to quickly move away into ditches, curbs, gutters, or other drainage systems. This helps maintain a safe and usable road surface in wet weather.

Fiberglass geogrid is a versatile and reliable material with many significant advantages in paving roads. With its high strength, durable construction, improved load bearing capacity, superior weed suppression, and improved drainage, it can significantly improve the performance of pavement systems.

Fiberglass Geogrid Technical Data:

Product specifications and performance parameters (geogrids of ordinary glass fiber type)

| Properties\specifications | FBG-B-25-25 | FBG-B-30-30 | FBG-B-40-40 | FBG-B-50-50 | FBG-B-80-80 | FBG-B-100-100 | |

| Strength (KN / m) | Longitudinal | 25 | 30 | 40 | 50 | 80 | 100 |

| Transverse | 25 | 30 | 40 | 50 | 80 | 100 | |

| Elongation at break% | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Grid (mm) | 12.5×12.5 12.7×12.7 25×25 25.4×25.4 25.7×25.7 30×30 40×40 50×50 | ||||||

| Width (m) | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Product specifications and performance parameters (glass fiber geogrid self-adhesive type)

| Properties\ specifications | GEO50-50 Self - | GEO60-60 Self - | GEO80-80 Self - | GEO100-100 Self - | GEO120-120 Self - | GEO150-150 Self - | |

| Strength (KN / m) | Longitudinal | 50 | 60 | 80 | 100 | 120 | 150 |

| Transverse | 50 | 60 | 80 | 100 | 120 | 150 | |

| Elongation at break% | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Grid (mm) | 12.5×12.5 12.7×12.7 25×25 25.4×25.4 25.7×25.7 30×30 40×40 50×50 | ||||||

| Width (m) | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | 1-6 | |

Remark:

The conventional fiberglass grid sizes are 12.7 mm and 25.4 mm.

Conventional widths are 2 m, 4 m, and 6 m.

The strength, width, and grid size can be customized according to customer's requirements.