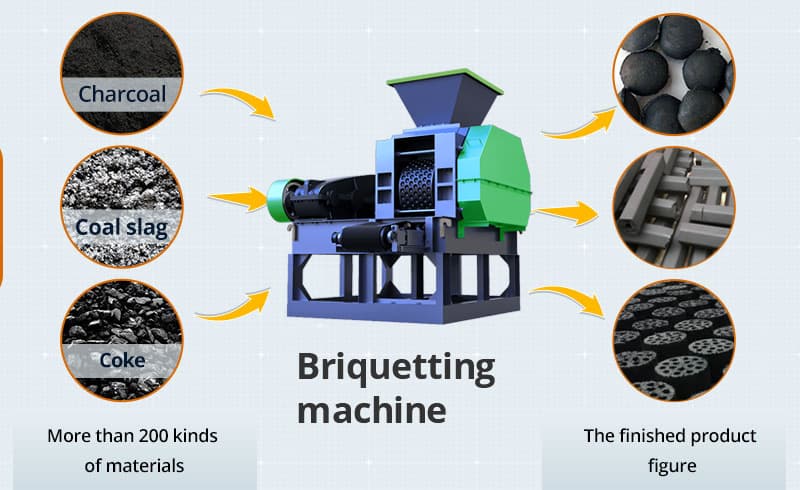

1. Applied Materials of briquette machine:

The Roller Ball Press Briquette Machine can be used to press various powders such as coal powder, iron powder, coking coal, aluminum powder, iron filings, iron oxide scale, carbon powder, carbon powder, slag, gypsum, tailings, sludge, kaolin, activated carbon, coke powder, various metal ore powder, non-metallic mineral powder, steel slag etc.

① Coal, charcoal, coke and other solid fuels briquettes in coal industry, blast furnace fuel industry, and power plant;

② Metal powder like iron ore powder, copper ore powder, etc. in steel making plant and metallurgical industry;

③ Solid waste like iron oxide, steel slag, etc. in metal waste recycling industry;

④ Charcoal briquettes production in barbecue and home heating.

2. The main accessories of the briquette machine:

The roller of the Gomine ball press is made of wear-resistant alloy, and the bearing adopts the rolling mill bearing series, which is quenched and tempered, which effectively improves the service life of the machine.

3. Kinds of Briquetting Machines:

In the whole briquetting plant, the briquetting machine plays a core and crucial part. The following paragraph mainly describes the types of briquette machine and their main usages:

①. Coal Briquetting Machine

Coal briquetting machine is mainly used in processing coal powder into balls. The materials can be directly put into the furnace for smelting, so as to increase the extra value.

②. Dry Powder Briquetting Machine

Dry powder briquetting machine is mainly used for pressing materials without water into bricks, such as lime powder, magnesium oxide powder, copper powder, chromium powder, zinc scrap, bauxite, non-ferrous metal powder, refractory material, ceramic material and so on. The powder material will be made into high capacity ball eggs through high pressure.

③. Mineral Powder Briquette Machine

Mineral powder briquette machine is mainly used for ball making of non-ferrous and ferrous metal mineral powder, and the materials can be directly put into the furnace for smelting, so as to increase the added value. For example, dust, sludge, oxide skin, slag, iron powder, aluminum ash, silicon manganese ore, etc.

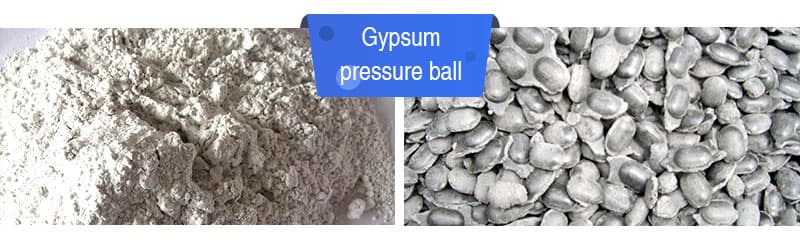

④. Desulfurization Gypsum Briquette Machine

Desulfurization gypsum briquette machine can press desulfurization gypsum powder into balls at one time, which has high yield and high ball forming rate. The equipment can press desulfurized gypsum powder into balls at one time without adding any adhesive, and the briquetting rate is above 90%.

⑤. Strong Pressure Briquetting Machine

Strong pressure briquetting machine is mainly used for the cold pressing pellet of refractory material, coal powder, coal slime, middling coal, coke powder, coke coal and metallurgical powder materials.

4. Instructions for Briquetting Plant:

The briquette plant is made with different equipment. Taking the charcoal briquetting plant as an example, here introduces the general briquetting plant flowchart.

The process of making charcoal briquettes can be divided into five steps: Ⅰ: carbonization Ⅱ: crushing Ⅲ: drying Ⅳ:mixing Ⅴ: briquetting Ⅵ: drying

| Model | Roll diameter(mm) | Capacity(t/h) | Power(kw) | Briquettes shape and size |

| YQ290 | 290 | 1-2.5 | 5.5-7.5 | Defined by users |

| YQ360 | 360 | 3-5 | 7.5-11 | |

| YQ430 | 430 | 5-8 | 15 | |

| YQ500 | 500 | 8-11 | 30 | |

| YQ650 | 650 | 10-15 | 37-45 | |

| YQ750 | 750 | 20-25 | 45 | |

| YQ850 | 850 | 20-28 | 55 |