Crimped wire screen is a high tensile wire screen suitable for quarries, sand and gravel pits and all types of ore treatment.

Atlas crimped screen is renowned for extremely high resistance to abrasion. Close checks on raw materials, production processes and constant quality control at all stages of manufacture guarantee a top quality finished product.

Four typical Crimped Mesh Patterns:

Flat Top

The top or working surface of the screen is smooth, all the crimping is on the underside, asssuring a more even weave. Materials are free to move over the screen.

Double Crimp

Evenly crimped in warp and weft, providing a rigid construction. The wires are undercrimped and sprung together thus giving a mesh which will not chatter at the intersections.

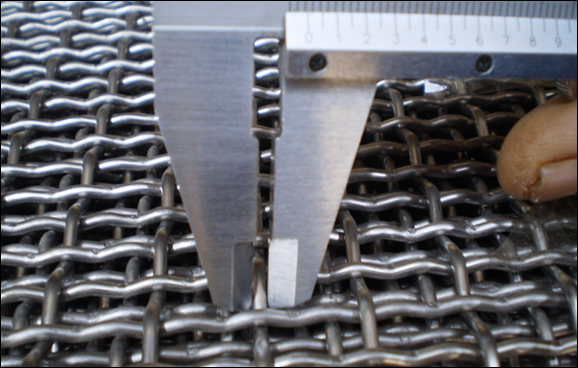

Lock Crimp

A variation of the double crimp with an additional crimp to give a firmly locked mesh. Widely used for vibratory screen cloths.

Corrugated Crimp

Extra crimps in war and weft with the wires seated in every third or fifth crimp. Gives a rigid mesh even when the aperture is large in relation to the wire diameter.

We supply:

Crimped Mesh Screen, 2.5mm Wire, Rectangular Opening

Woven of pre-crimp wire:

| Opening (mm x mm) | Wire Dia (MM) | Size (m x m) | Type |

| 13 x 6 | 2.5 | 1.5 x 1.5 | Crimped |

| 7 x 3 | 2.5 | 1.5 x 1.5 | Crimped |

| 3 x 13 | 2.5 | 1.5 x 1.5 | Crimped |

| 7 x 3 | 2.5 | 1.5 x 1.5 | Crimped |

| 2 x 5 | 2.5 | 1.5 x 1.5 | Crimped |