Screen baskets are essential screening and filtering equipment and component in the papermaking process. They are used to ensure that the paper fibers are evenly distributed in the water before being laid on the paper machine and to remove any large particles or impurities from the pulp.

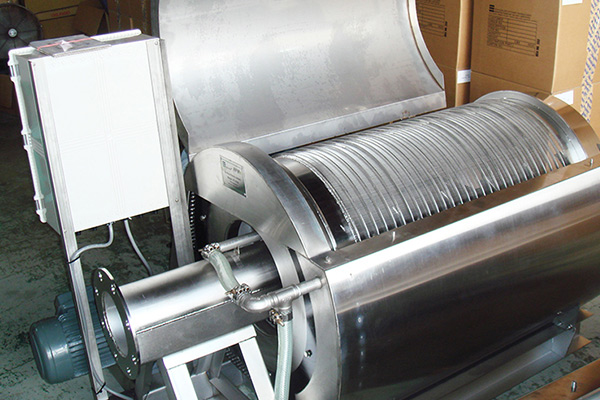

Our screen baskets are made of high-quality stainless steel. The wedge wire profiles are welded and wound around support rods. The wedge wire screen basket for paper making has many benefits, such as compression resistance, durability, precise filtration, and customizability.

How does the screen basket work in papermaking?

The refined pulp is fed into a paper machine, which consists of a series of rollers and screens. The pulp is spread out onto a moving screen, where the water is drained away and the fibers begin to bond together.

The screen basket is placed in the headbox of the paper machine, where the pulp is introduced. As the pulp flows through the screen basket, the water is drained away, leaving behind the fibers.

What are the benefits of using wedge wire screen baskets in the papermaking process?

1. A wedge-shaped wire screen structure with a narrow top and wide bottom gap, a uniform screening slot, stable welding quality, a high opening rate, and high screening efficiency.

2. Superior rigidity and load-bearing capacity, and prevention of clogging, can effectively reduce papermaking downtime and maintenance costs.

All in all, screen baskets play a very important role in the papermaking process.

Related Reading: