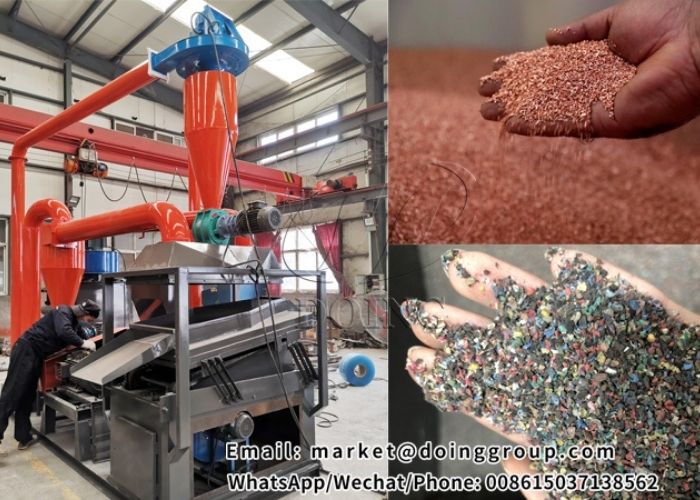

Copper wire recycling machine is called as copper wire granualator machine, which is used for recycling all kinds of scrap cable wires to separate copper and plastic. It can handle some raw materials including copper wire, telephone wire, communication line, control panel line, industrial copper wire and other scrap wires and cables.

The processing of copper wire recycling machine can be divided into the following steps. First, all kinds of scrap cable wires go into the shredding machine through the conveyor belt and shred into 5 to 7 cm pieces and then into the crusher for secondary crushing, separated from 2 to 3 mm metals and small plastic particles. Among them, the crushing system uses the SKD-11 alloy cutter, with high hardness, high toughness and long service life characteristics; But because the separated material may contains some iron, failure to separate the iron can effect the purity and price of the copper, so these material will go into a magnetic separator to remove iron; Second, due to the different specific gravity of plastic and metal, then they are separated into metal and plastic by air separation; Last, for some thin wires less than 3 mm in diameter, the relative content of 99% copper and plastic can be separated by electrostatic separation according to the difference between metal and plastic conductivity.

In the whole process, copper wire recycling machine totally adopts dry and physical separation and pulse dust collector method, which have low noise, no pollution and meet the requirements of environmental protection. Besides, copper wire recycling machine also adopts integrated type design and occupies a small land size; Meanwhile, it fully adopts automatic PLC control system and easy to operate.