Aluminum plastic recycling plant can process waste aluminum-plastic

composite materials to get aluminum and plastic for reuse. The recycled

aluminum and plastics are powder and can be sold directly on the market

at a high price.

Application scope of aluminum plastic recycling plant:

Waste aluminum plastic and waste aluminum foil plastic come from the

corner waste of pharmaceutical factories, aluminum plastic plate

factories, food and beverage factories and other aluminum foil packaging

industries, waste flexible packaging bags, capsule plates, toothpaste

skin, wahaha bottles, etc.

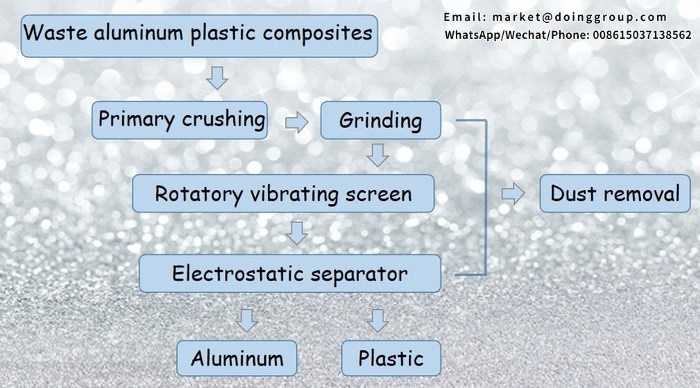

Production process of aluminum plastic recycling plant:

Aluminum and plastic can be completely separated from waste

aluminum-plastic materials after crushing, grinding, eddy-vibrating

screen and electrostatic separation. With the use of high-voltage

electrostatic separator, the separation rate can reach 99.9%, both the

aluminum and plastic is very pure.

Products separated by aluminum plastic recycling plant:

The separated aluminum powder can be used for smelting aluminum ingots,

and aluminum powder is also the first-class raw material for silver

powder factories, fireworks factories, and aluminum factories. According

to our investigation, at present, this product is in short supply and

the market potential is huge. Plastic granules can be compressed, made

into tubes and used for packaging and water pipelines.

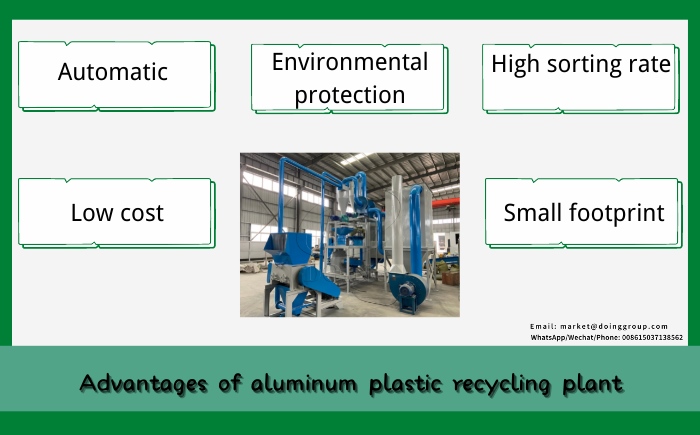

Features of aluminum plastic recycling plant:

In the production process of DOING aluminum plastic recycling plant,

water cooling system are added to solve the problem that the waste

material is not completely separated from non-metals due to excessive

temperature during the grinding process. In addition, dust would be

collected by pulse dust collector during the production process, thus to

keep clean working environment.

DOING aluminum plastic recycling plant completely adopts dry physical

separation method, without any pollution to the environment, it is the

best choice for aluminum-plastic recycling business.