Aluminum plastic separation machine is used for recycling of waste aluminum-plastic material. It used physical method which is eco-friendly technique to separate aluminum and plastic from scrap aluminum-plastic material such as aluminum-plastic medical blister packing, aluminium composite panel, aluminum foil, aluminum tubes.etc...

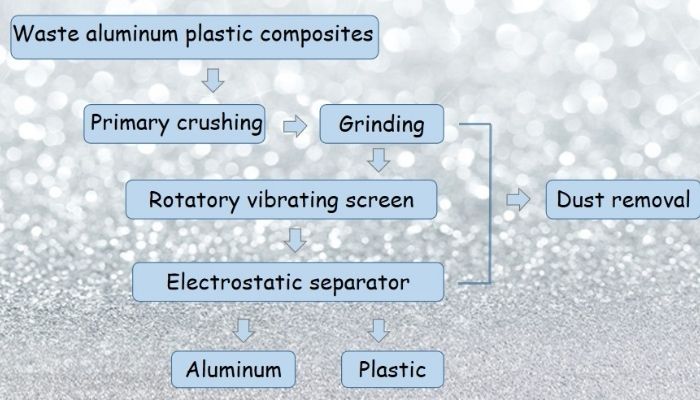

The whole process to recycle aluminum plastic material include crush scrap material to small pieces by crusher then grinding pieces to powder which aluminum and plastic doesn’t stick together. And we use the eddy vibrating screen to sort out the bigger pieces to go into the grinding machine again to make sure all pieces will grind to powder, also we equipped with water cooling system to make sure the plastic not be melted or discolored by high temperature during the crushing and grinding process. After all above process, powder will go to electrostatic separator which aluminum and plastic will separate totally. And pulse dust collector system will collect all dust during whole process. The entire production process is free of water, smoke, and dust pollution. Besides, The whole process of the aluminum plastic separation machine is controlled by PLC, which is fully automatic to work, easy to operate.

Aluminum plastic separation machine use totally dry type and physical separation method, without using water, fire, chemical, completely environmental friendly and pollution free. And the separation rate of our aluminum plastic separation machine could reach to 99%, which the recycled aluminum could be directly used for smelting aluminum ingots, or directly used in aluminum powder factory , firework plant and aluminum plant, while the separated plastic can be used to make plastic sheet, tubes, package and water pipes.

DOING Company is a manufacturer specializing in the manufacture of aluminum plastic separation machine, welcome your call.