The aluminum plastic separation recycling machine

has a lot of advantages, like low cost, high separating rate and high

working efficiency. And it is very easy to operate, just needs 4 steps,

aluminum will separate from plastic quickly.

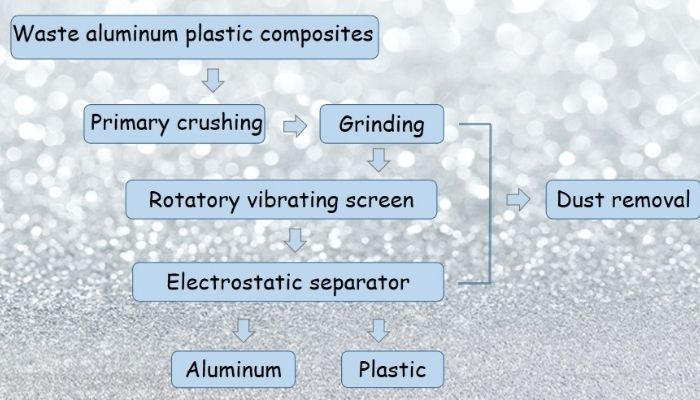

The process of separating aluminum from plastics by the aluminum plastic separation recycling machine is as follows:

1. Crushing

put the aluminum and plastic products into a crusher to break them into smaller particles.

2. Grinding

broken aluminum particles for grinding, are processed into powder.

3. Spin vibration sieve

The powder mixture of aluminum and plastic was put into the spin vibration sieve for screening, and the larger particles were screened out for grinding again;

4. Electrostatic separation

the small particles after the treatment of rotary sieve for electrostatic separation, so as to separate aluminum and plastic powder.

Aluminum plastic separation recycling machine equipped with dust removal device, will not cause secondary environmental pollution, and low cost, simple operation. It is the best choice to use the separation equipment to separate the aluminum from the plastic.