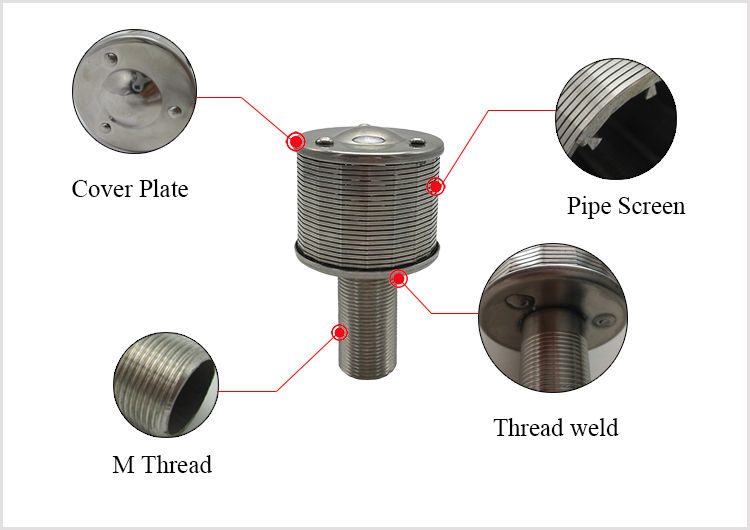

Wedge wire water treatment sand filter nozzles are made from V-shaped profile wire, which is spirally wound around a cage of longitudinal support rods. Each intersecting point of these wires is fusion welded, with a unique welding process. This spacing gives passage for water to enter. The entire process is completed on fully computerized machines. The pitch of winding gives different spacing between two adjacent turns of wire.

Application of wedge wire screen nozzles

Widely used in water softening treatment equipment, replace Polypropylene ( PP ) filter; sand filters, carbon filters, ion exchange systems, carbon absorbers, media retention, backwash retention, resin retention, and resin traps.

Advantages of wedge wire screen nozzles

1) Type 316L stainless steel construction.

2) Continuous slot design provides a large circulation area

3) Standard nozzle is 2in/51mm diameter and can be attached to the plate either with threaded end fittings or "L" blots.

4) Standard slot opening typically ranges between 0.006”(0.15mm), and 0.020in./0.50mm wide suitable for 40 to 50 mesh size media, Other slot sizes are also available.

5) Wedge wire screen is highly resistant to plugging.

6) Choice of either 3/4” NPT or 1” NPT fittings are available from stock. Other styles, such as tee-bolt mountings, and drop tubes are readily available.

7) Unaffected by temperature, corrosion-resistant, aging resistant, long life span, easy change, safety, and environmentally friendly.