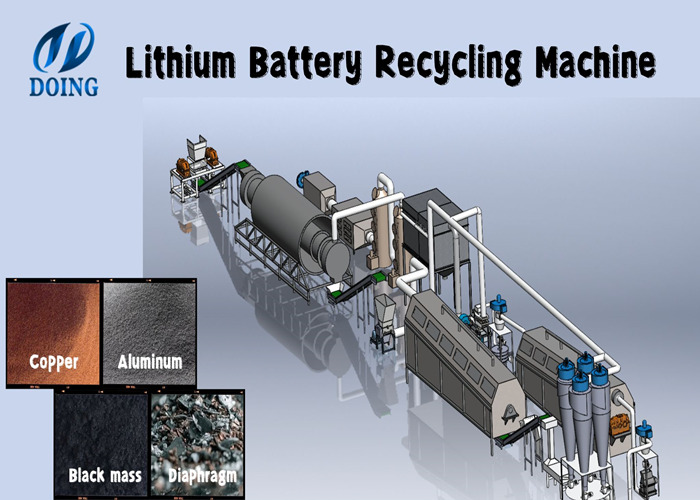

DOING lithium-ion battery recycling equipment mainly separates these highly valuable products through the processes of discharge, shredding, carbonization, crushing and screening.

The introduction of the lithium battery recycling technology:

1. Cut the anode material of the disused waste lithium battery into a sheet, and then put it into a hammer crusher to hammer and vibrate the carbon powder and acetylene black powder adhered to the surface of the negative electrode copper foil.

2. Set a sieve plate at the lower part of the rotor of the hammer crusher, and crush the negative particles smaller than the aperture of the sieve plate by hammering through the small hole of the sieve plate and fall into the screening equipment below.

3. The anode material with a size larger than the aperture of the sieve plate is crushed by the hammer in the hammer crusher until the size is smaller than the aperture of the sieve plate.

4. The crushed particles falling into the sieving equipment utilize the size difference and shape difference between the particles to vibrate and sieve to separate the metallic copper from the non-metallic carbon powder and acetylene black powder after the hammer vibration peels off.

The lithium battery recycling technology has achieved industrial automation, high recycling efficiency and strong processing capacity. The recycling rate of valuable components of waste lithium batteries has reached more than 90%, and the entire production process will not produce any secondary pollution.

The benefits of the lithium battery recycling machine: