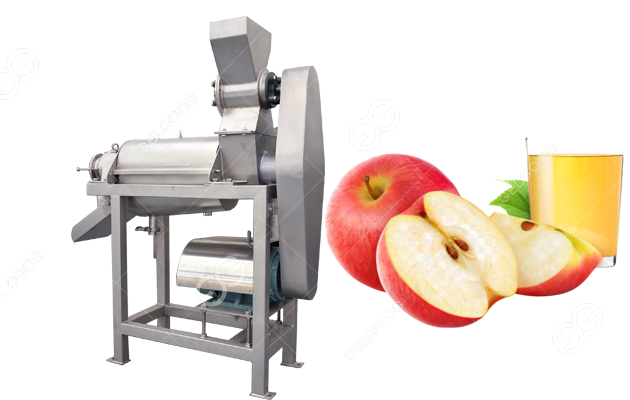

The apple juice processing machine for fruit juice making is a combination of crushing and spiral juice extraction. It crushes fruits and vegetables first and then squeezes the juice. It is mainly suitable for crushing and squeezing various berries, pome and various vegetables. The juice yield reaches 45%~65%.

The apple juice squeezer contains of a hopper, a crushing device, a front support, a screw, a filter, a juicer, a rear support, a slag trough and other components. The left end of the screw spindle is supported in the rolling bearing seat, and the right end is supported by the handwheel. In the bearing seat, the electric motor drives the spiral through the V-belt pulley to work.

The main component of this apple juice processing machine for fruit juice making is a crushing device installed on the feed hopper. There are four sets of flying knives and a set of bottom knives on the rotor. The flying knives rotate around their own axis in the fixed bottom knife gap, so can obtain the fruits and vegetables.

The granularity is 2-5 mm and it is crushed directly into the spiral juice extraction system to improve the juice extraction effect. The main component of screw squeezing is the screw. The bottom diameter of the screw is gradually increased along the direction of the slag outlet and the pitch of the screw is gradually reduced. When screw push the material,the screw volum cavity reduce,forming a squeeze of the material.

When looked from the feed hopper to the slag tank through,the rotation direction of the screw rod is clockwise.Put the raw material to hopper, pressed it by screw rod.The squeezed juice flow into the juicer through the filter, while the waste is discharged through the air formed between the screw rod and the pressure-regulated cone.We can adjustable the header apace along the axial movement.

By changing the size of the space, can adjust the resistance of slagging to change the slagging.However, if the space is too small, under strong extrusion, part of the slag particles will be squeezed out through the filter together with the juice. Although the juice output increases, the quality of the juice decreases. The size of the gap should be determined by the user’s specific process requirements set.

| Model | Capacity | Power(KW) | Size |

| GG-0.5 | 0.5T/H | 1.5+0.55KW | 900*320*1100MM |

| GG-1.5 | 1.5T/H | 4+1.5 KW | 1560*450*1640MM |

| GG-2.5 | 2.5T/H | 11+2.2KW | 2200×600×1960MM |