Water Distributor is to arrange the water volume according to a certain rule in a certain working area. The most common is to distribute water evenly on the working surface. The device that accomplishes this task is called a water distributor. The conventional material is 304 stainless steel, which can also be customized to 316 stainless steel. The 316 material can be used in the corrosive filter equipment to prevent water corrosion. Usually used in mechanical filtration equipment, activated carbon filtration equipment, softened water treatment equipment, demineralized equipment. It can also be applied to various valveless filter tanks, filter tank bottom filter, etc.

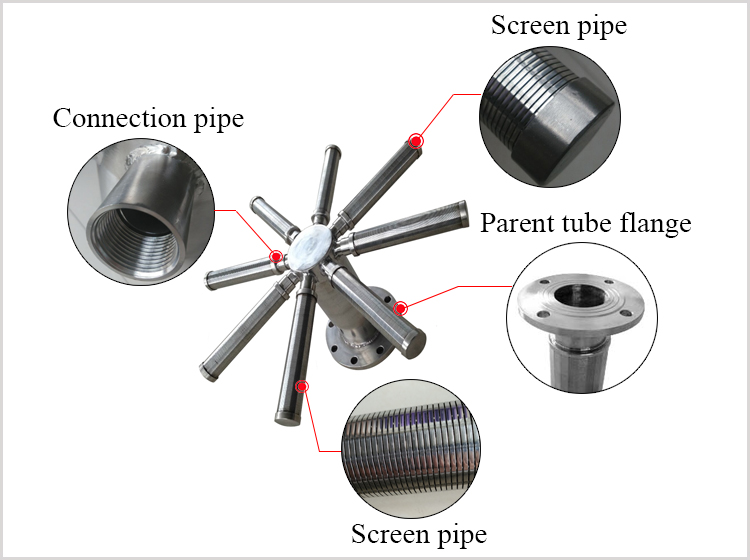

Wedge wire lateral assemblies, also called header lateral assemblies, are assemblies of horizontal herring bone style wedge wire screen laterals and vertical secured round hub. The screen lateral has an inherent even pattern, which is made of stainless steel, Hastelloy alloy steel, and other alloy steels.

Wedge wire lateral assemblies are made of several wedge wire screen laterals and supporting round hub. There is thread ending and flange ending wedge wire screen laterals for choice to suit different machines.

Because of the different lateral endings, the connection types of lateral assemblies are also different including thread connection and flange connection. Featured by the different designs, wedge wire lateral assemblies are widely used in under draining applications for filtering. Besides, it also can be used in various machines for screening.

Because of the different ending of wedge wire screen lateral, the connection type is different. Commonly the wedge wire screen laterals are installed onto the vertical hub by threaded. Sometimes, the screen laterals are bolted onto the round hub through flanges on the screen laterals and round hubs.

Hub radial lateral is another type of lateral assemblies. It is composed of several screen laterals and a central hub.

Hub radial lateral assemblies have lots of specs, including the slot size, screen lateral lengths, and assemblies diameter. Additional, the number of screen laterals can be customized. All size can be customed.

The application of Wedge Wire Lateral Assemblies:

Wedge wire lateral assemblies are widely used in under draining applications for filtering and screening, additional, it is widely used in various machines for screening.

Under draining filtration

Ion exchanger

Cation exchanger

Mixed bed exchanger

Details:

material | SS304, SS304L, SS316, SS316L, SS321, 904, C276, 2205, 2207, Duplex, Hastelloy, etc | ||

Normal Lateral Tube QTY (PCS) | 4, 6, 8, 12,16, etc. According to request, actual flow rating, and application. | ||

Lateral OD Range (mm) | 25 to 80mm, customized | ||

Normal Hub (mm) | 108, 133, 219, Customized | ||

Hub and lateral connector types | Thread, Flange | ||

Diameter Range(mm) | According to the tank diameter. (Usually 200mm shorter than tank diameter) | ||

Slot Range(mm) | Normal slot 0.2, 0.25, 0.3, 0.35, 0.4mm.Slot according to request. | ||

Wedge Wire(mm) | 1x2 | 1.5x2 | 2x3 |

Support Rod (mm) | 1.5x2.52x3 | 1.8x2.52x3 | 2x32x4 |

Note | Customized According To Requirement | ||