|

FEATURE •360° exhaust direction•"Partial sequential mode" safety system•Light die cast body of aluminum alloy•Top loading design•Remain nails display available•Non-marring tip available |

|

| Tool Diamensions: | 355*85*295mm (13.98*3.35*11.61 in.) |

| Net Tool Weight: | 2.65kgs (5.83 lbs) |

| Operate Pressure: | 5~7.5Kg/cm2 (75~110Psi) |

| Load Capacity: | 150 Staples |

| Quality | Industrail Quality |

| Certificate | CE,ISO9001:2008 |

| No. | Symptom | Problems | Solutions | |

| 1.1 | Air Leak | Air leak in the cylinder cap when tools don't work | 1.Loose head valve piston seal or o-rings . | Check and replace the head valve piston set |

| 2.Worn or damaged o-ring or cylinder cap gasket under cylinder cap | Check and replace o-ring or cylinder cap gasket under the cylinder cap | |||

| 1.2 | Air leak in Trigger area when tools don't work | 1.Damaged o-ring in trigger valve | Check and replace o-ring | |

| 2.Damaged o-ring in trigger valve stem | Check and replace o-ring | |||

| 3.Dirt in the trigger valve | Check and clean the trigger valve | |||

| 1.3 | Air leak in cylinder cap when tools are working | 1.Damaged head valve piston o-rings | Check and replace o-rings | |

| 2.Damaged seal under cylinder cap | Check and replace seal | |||

| 1.4 | Air leak in nose when tools are working | 1.Worn or damaged bumper | Check and replace bumper | |

| 2.Loose driver(piston unit) thread | Check and replace driver(piston unit) | |||

| 1.5 | Air leak in Trigger area when tools are working | 1.Worn or damaged trigger valve head | Check and replace trigger valve head | |

| 2.Damaged head valve piston o-rings | Check and replace head valve piston and o-rings | |||

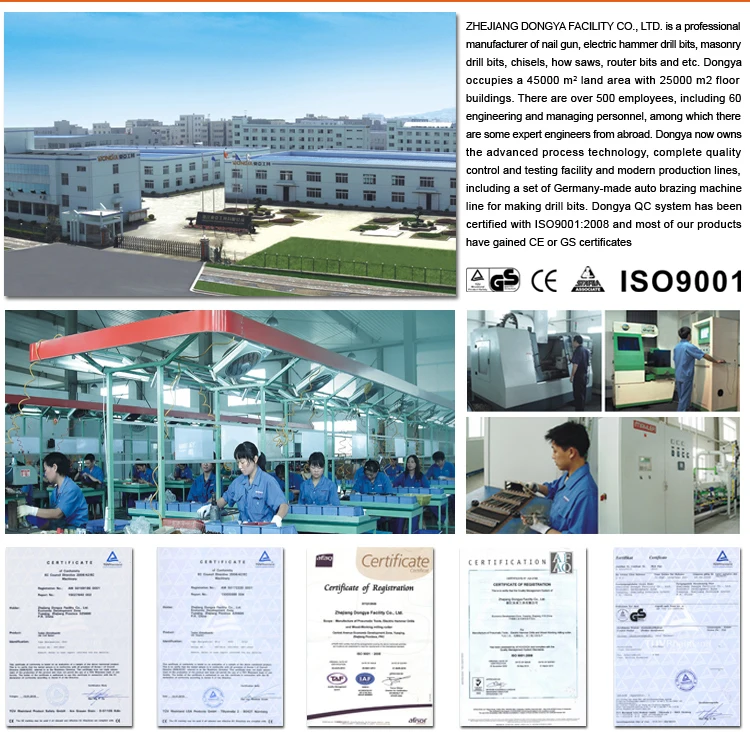

1) 35 Years Production Experience

2) 16 Years Alibaba Gold supplier with High Reputation

3) Alibaba Trade Assurance USD20,000

4) 100% QC Inspection before Shipment

5) Engineer Team from Taiwan

6) Competitive Price

7) Lifelong After-Sale Service

8) Advanced Machines

9) CE Certificate and ISO 9001:2008

10) OEM Available

11) Sample Available