Villa use light gauge steel framing

Introduction of the light gauge steel framing system

Light gauge steel framing is fabricated and delivered direct to site with 3D models and layout plans for easy and fast on site installation by builder recommended installers.

Lightweight steel materials provide protection against rotting, termites, warping, twisting or shrinking

Using light gauge steel lowers building dead loads and provides a straight, true and accurate framing alternative, customised to your design specifications.

Engineered internal and external stud wall systems are manufactured in various widths and gauges to suit the project specifications. Wall frames are custom designed and shop detailed to incorporate services and custom hole locations as required. Open web floor joists are fabricated for greater strength

Our framing systems are ideal for low to mid rise projects including apartments, townhouses, units, aged care, nursing homes and schools.

Design Options

The versatile system provides extensive design choices, no matter it is an existing design, working with our expert team to develop a custom design or a selection from our collections.

Software

Intelligent software by FrameCAD streamlines engineering, designing and detailing processes; ensuring house can be repeatedly built and easily duplicated, while being strong, durable and fit for purpose. It can conform to Australia Standard, New Zealand Standard, USA Standard, and Europe Stand.

On-site Erection

WZH Simple construction methods, training and support enable buildings to be assembled quickly using common tools and local labor even in remote and challenging environments.

Detail introduction of the light gauge steel keel

| No. | Item | Detail |

| 1 | Section Size | C 89*41*11 |

| Thickness | 0.75-1.2 mm , 0.8/1.0 mm is the most used | |

| 2 | Material Grade | G550 Galvanized Z275 |

| 3 | G550 Galvalume AZ150 | |

| 5 | Length | suitable length cutted as the design and transport |

| 6 | Package | by bundles |

| 7 | Service | Pre- assemble service is available |

| 8 | Design software | FRAMECAD |

| 9 | Application | Shopping Malls, Churches, Retail Stores, Entertainment venues, Schools, Condominiums. , workshop, warehouse , office buildings, hotels , family living house etc . |

| 10 | MOQ | 5 tons |

| 11 | Origin | Hebei , China |

Service / Web Hole

The service / web hole can be seleceted when placing an order. It can be punched into the studs and plates where cabiling or plumbing is required or for joining walls together

Dimple

The dimple holes are punched in the center of the flange. They accurately locate the joining components and are recessed so that the head of the screw sits flush and allows the drywall to fit flat on the framing

End Bearing

The machine cut-off produces an end-bearing stud that allows the stud rather than the fixing to carry the load exerted on the frame. The development of "true load bearing frames" has allowed the construction of high rise light steel-framed buildings.

Printing

Information are printed onto the stud, including component numbers, customer name, job number/description, operator information and identify the exact component orientation.

Production and Package

Installation and accessories

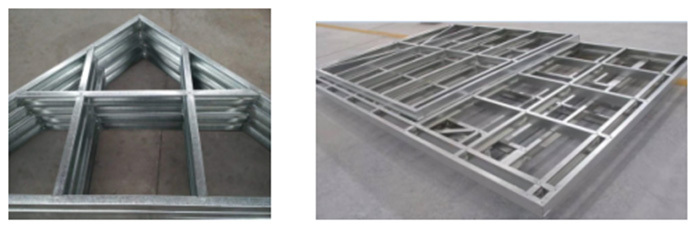

Assemble parts for the roof truss and wall frame

Assemble at the building site

Connection points

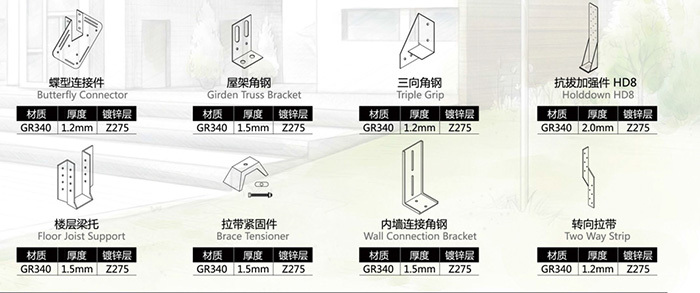

Accessories

Applications1. Residential building 2. Bus station

2. Bus station 3.Curtain wall

3.Curtain wall 4.Mobile homes

4.Mobile homes  5.Warehouse

5.Warehouse 6.balustrade

6.balustrade