More Superhard diamond / CBN grinding disc including resin diamond / CBN grinding disc, vitrified diamond and CBN grinding disc, double-disc surface grinding disc, pellet grinding wheel and so on.

Application Fields Of Diamond/ CBN Grinding Disc

|

Diamond / CBN grinding disc, grinding wheel

|

|

Seal

|

engineering ceramics, double metal composite sheet

|

|

Tools

|

cemented carbide, ceramet

|

|

magnetic materials

|

soft ferrite,NdFeB magnetic.

|

|

high pressure vane pump

|

blade, rotor, stator

|

|

air conditioning compressor parts

|

Cylinder Block (Grey Cast Iron or Nodular Cast Iron), Sleeve (Alloy Cast Iron), Slide (High Speed Steel) , piston.

|

|

others

|

Automobile, motorcycle piston ring, engine thrust plate

|

The Case Of Diamond / CBN Grinding Disc, Pellet Grinding Wheel

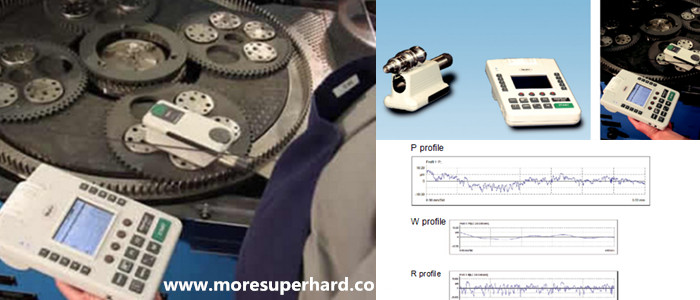

Our customer tested surface roughness of workpiece by MarSurf M 400. The results show that the workpiece has the much stable performance and good surface roughness by using our diamond grinding disc.

Application of Resin diamond grinding wheel

1: machining tungsten carbide

2:ceramic materials

3:magnetic materials,

4:silicon materials

5:thermal spraying alloy materials

Resin diamond wheel products

1:resin cup diamond wheel

2:resin diamond polishing wheel

3: CNC resin diamond grinding wheel

4:resin diamond cutting wheel

5:resin diamond wheel for glass

6:resin centerless grinding wheel

Production process of Resin bond diamond grinding wheel

1. Mix: the binders and diamond powder are fully stirred and fused in a certain proportion

2. Weighing: weighing according to the volume, ring width and density of the grinding wheel required by the customer

3. Feeding: put mixed diamond powder and binding agent into the grinding tool

4: compression ring (let stand for a period of time to wait for molding)

5: back mould

6: the abrasive layer is air-dried

Cook for 10 hours at 7:670 degrees

8: cooling (prepare the matrix at the same time)

9. Fixed decoration of the whole

10: measure stationarity

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasive diamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

1.Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

2. Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

3.Woodworking saw blade and tools .

4.Hss tools

5.Cutting wheels

Products Range:

1. vitrified bond/resin bond/Metal bond/Electroplated diamond grinding wheel & other diamond tools2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits6. PCD tool grinder & PCD grinding machine

|

Our product’s advantages:

1.High grinding efficiency

|

|

2.Wonderful edge quality

|

|

3.Long service life

|

|

4.High polishing efficiency

|

|

5.Large Exports

|

|

6.Considerable after-sell service

|

|

7.Amazing performance

|

|

8.Various types and sizes available

|

|

9.Direct Factory Manufacturer

|

|

10.Backing/substrate material: Aluminum

|

|

11.Abrasive layer: diamond

|

|

12.Bond: vitrified

|

|

13.Excellent cutting edges

|

|

14.Reduced cycle times

|

|

15.Custom Engineered

|

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com

To meet your requirements in every way, we need the following information

----- Shape and Dimension of the wheels

----- Grit size (Mesh, refer to Table#1)

----- Concentration

----- Bond(Resinoid, Vitrified, Metallic, Electroplated)

----- Quantity