Salt Fog & Salt Spray Corrosion Tests in Artificial Atmospheres Tester

Application:

Salt fog spray corrosion test cabinet can be used for all kinds of material surface treatment, including coating, electroplating, organic and inorganic coating, anodizing, rust proof oil and preservative treatment test of its corrosion resistance, so as to establish the quality of the products.

Specifications:

|

Model |

ASR-60A |

ASR-90A |

ASR-120A |

ASR-200A |

|

Standards |

ISO9227, CNS3627,3885,4159,7669,8886, JIS D-0201, H-8502, H-8610, K-5400, Z-2371, ISO 3768, 3769, 3770, ASTM B-117, B-268, GB-T2423, GJB 150. |

|||

|

Test chamber capacity (L) |

108L |

270L |

600L |

1440L |

|

Temperature |

Test chamber |

NSS.ACSS 35°C±1°C/CASS 50°C±1°C |

||

|

Air cylinder |

NSS.ACSS 47°C±1°C/CASS 63°C±1°C |

|||

|

Test chamber size LxWxD(cm) |

60*45*40

|

90*60*50

|

120*100*50

|

200*120*60

|

|

Max volum of test liquid (L) |

15 |

25 |

40 |

40 |

|

Volume LxWxD(cm) |

107*60*118 |

141*88*128 |

190*130*140 |

270*150*150 |

|

Power |

AC220V,10A |

AC220V,15A |

AC220V,30A |

AC220V,30A |

|

Spray quantity |

1.0~2.0ml/80cm2/h |

|||

|

PH |

6.5~7.2 3.0~3.2 |

|||

Customize parts for Corrosion Test Chamber:

1. Inner chamber size

2. Inner chamber structure

3. PID programmable controller or PLC touch screen controller

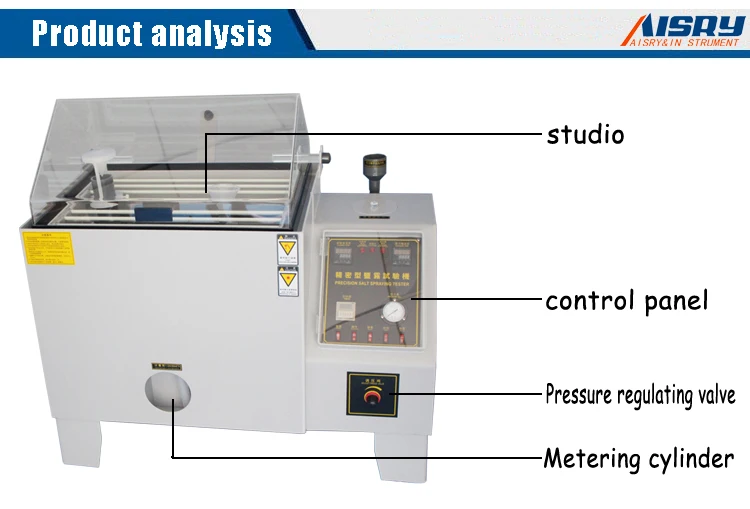

Features:

1.LCD display and a pid controller or touch screen programmable controller.

2.Entire PVC sheet material, the internal ring with the use of advanced three-dimensional flutter high technology products,strong structure, fresh, never deformation and acid and alkali, high temperature and never aging, for salt spray, copper acetate, and other test specifications.

3.Controller are in the same panel, the operation simple and clear.

4.Neutral salt spray (NSS), acetic acid salt spray ( AASS ), copper accelerated salt spray ( CASS ) either of the test laboratory.