double layer steel structure :6500㎡

provide you safe and economic building:

1.size: length x width x eave height, roof pitch

2.materials for wall and roof panel and thickness

3.window and door: type, size, quantity and position to place

4.wheather need light tranmitting panel and ventilator

5.if crane is needed and lifting weight

6.if downpipe and gutter is requested

Acceptable reliability under earthquake action

|

Building risk categories I and II |

|

|

All or part of the structural collapse Failure may result in life hazard |

The probability of occurrence of the largest earthquake 10% The probability of occurrence of maximum seismic effects is 25% |

|

Building risk category |

|

|

All or part of the structural collapse Failure may result in life hazard |

The probability of occurrence of the largest earthquake is 6% The probability of occurrence of the largest earthquake is 15% |

|

Building Risk Category IV |

|

|

All or part of the structural collapse Failure may result in life hazard |

The probability of occurrence of the largest earthquake is 3% The probability of occurrence of the largest earthquake is 10% |

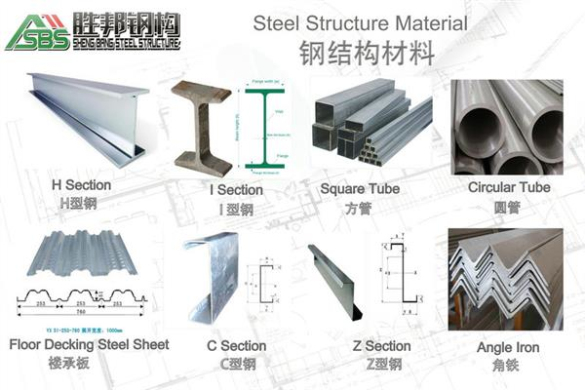

1.The detail material for the steel structure

The steel structure material is included the H section,I section,Square tube,Circular Tube,Floor decking steel sheet,C section,Z section,Angle iron , Steelbar ,Steel plate .

1)Z-Section SheetZ steel is common cold bending thin-wall steel, whose thickness is commonly between 1.6-3.0mm, section heights between 120-350mm. Processing materials is hot rolled (paint), galvanized. It is processed according to perform standards. Z steel is usually applied in large steel structure factory building.

2)Hot rolled I-shape beams can be divided into common i-steel and light beams.

Common i-steel Main purpose: Ordinary beams are widely used in various building structures, Bridges, vehicles, support and machinery, etc. Light beams Flange of common i-steel and light beams are gradually becoming thinner from root to the edge with certain angle. Compared with ordinary beams, hot rolling light beams has wider leg and thinner waist in same wait height conditions. Guaranteed the bearing capacity, the light beams have better stability, metal saving and better economic effect than ordinary beams. Main use: The same with ordinary beams, it is mainly used in factories, Bridges and other large structures and vehicle manufacturing, etc.

2.Product details

|

Product Name |

Prefabricated Steel Structure Warehouse |

|

|

Specification |

Foundation |

Concrete and Steel |

|

Support |

X or V types, angle steel or round tube |

|

|

Surface |

Two layers and anti-rust paint |

|

|

Color |

White, Grey, Blue, Green, etc |

|

|

size |

Designed by your requirement |

|

|

Advantages |

1. Stable Construction2. Anti-seismic performance3. Aesthetic appearance4. Short construction period5. High-speed installation6. Life span durability7. Environmental-Friendly product8. Energy saving |

|

|

Main component |

Base materials |

Cement and steel foundation bolts |

|

Main frame |

H beam (welded or hot rolled) |

|

|

Material |

Q35B,Q345B |

|

|

Purlin |

C purlin (C120-320) or Z Purlin (Z100-200) |

|

|

Bracing |

Tie bar, lateral bracing, column bracing, knee bracing, etc |

|

|

Bolt |

Normal bolt, high strength bolts, Galvanized bolt |

|

|

Roof & wall |

Sandwich panel, steel corrugated sheet |

|

|

Door |

Sliding door , rolling shutter |

|

|

Window |

PVC window, aluminum-alloy Window |

|

|

Accessories |

Skylight, ventilation, downpipe and galvanized gutter etc . |

|

Wind load design terms

Basic wind speed V: 10 m from the ground height, exposure category C, time interval of 3s, according to 26.5.1