With the rapid development of the world plastic industry, more and more plastic materials are used widely than before. As the increasing quantity application of plastic, it brings people convenience as well as serious pollution problems. At present, the waste plastics mainly are solved by landfill, burning and recycling. However, both of landfill and burning cause the secondary pollution, and the scope waste plastic recycling is very limited. For example, the waste plastics produced by household garbage and paper-making factory, which can not be recycled. With the increasing price of International crude oil, the waste plastic pyrolysis plant project report is closely watched by different countries in the world.

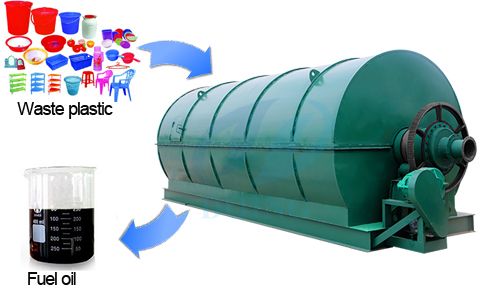

This plastic

pyrolysis plant applies pyrolysis technology which can convert plastics into fuel oil and carbon black. All of them have a wide range of applications and can create high benefits for you. The fuel oil can be widely used in industries such as steel and iron and boiler factories, ceramics, power or chemical industries etc. or used for generators to get electricity. Carbon black can be used for making construction bricks with clay, or used as fuel

Features And Advantages Of Waste Plastic Pyrolysis Plant

(1)High quality: all of our plants have passed CE, ISO, SGS certification.

(2)High oil output: unique catalyzer and condenser which can increase oil yield by another 5% and improve oil quality.

(3)High efficiency: the reactor of the plant is 360-degree rotating and its rotate speed can reach 0.4-0.8 turn/minute. This special design makes the bottom of reactor get heated evenly, which can improve the pyrolysis efficiency.

(4)Safe: our plants are equipped with mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, which will guarantee safety in production.

(5)Energy saving: by the extra gas recycling system, the gas generated in the pyrolysis process can be reused, which will save energy.

(6)Environment friendly: in the de-dusting system, three steps are used to dedust the extra gas. More than 95% of the dust would be removed. The released gas is pollution-free and can be discharged into the air directly.

(7)Longer service life: the technology of avoiding the reactor of being burnt through by reforming the furnace, which will lengthen the life span of the main reactor for 2 to 3 years. The service life of our plant can reach 5-8 years.

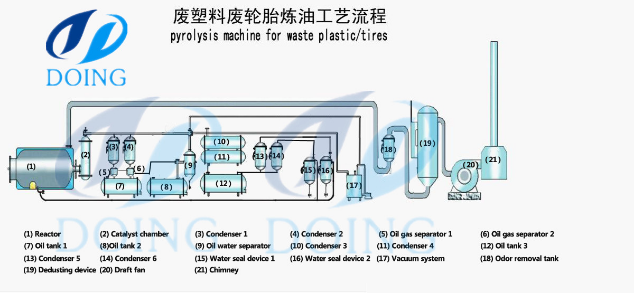

The Perfect Solution (Pyrolysis Process): Pyrolysis is the decomposition of organic compounds unde r oxygen free (anaerobic) atmosphere that produces gas, oil, carbon black and steel. Efficient indust rial Pyrolysis is a process to treat the rubber and industrial plastic wastage as well.

As a result of pyrolysis of wastage tyres one obtains,

Fuel oil application

1. FUEL OIL (40% to 45%) The main oil product produced by our recycling applicati on is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45 % of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

2.CARBON BLACK (30% to 35%) Carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% (depending on the type of tyres) o f the total amount of scrap tyres recycled in the system. Carbon black is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens, lengthens th e endurance, and improves the coloring features of the materials.

Carbon black produced by Pyrolysis process (CBp) is more eco nomical compared to carbon black produced primarily from petroleum and is more price-ef ficient to be used as an ingredient in the industries listed;

Electric cable jacketing

1.Conveyor band

2. Carrier Bands

3. Hose and doormat

4. Black nylon bag

5. Rubber additive

6. Automotive spare parts

7. Heat isolation

8. Black colorant in rubber materials

9. Plastic pipes

10. Industrial rubber products

11.Fire fighting

STEEL WIRE (10% to 15%) Tyres contain steel wires and the amount range of 10% t o 15% of the total tyre wastage. All of the steel present in the tyre can be detached after pyrol ysis recycling process in completed. Valuable steel wires are pressed and sold to steel and scrap dealers.

GAS (10% to 12%) Non-Condensable gases arise during the pyrolysis process. Some advantages such as..... It has higher calorific value as compared to Natural Ga s.

1. It can be replaced where Natural Gas and Propane are st ored. ? The high energy gas may be utilized as a source of ener gy for the Pyrolysis process.

2. The amount of gas generated in the system is 12% to 15% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity, the facility generates 1200-1500 m3/day gas, which has an enormous energy potential when evalu ated.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2