Basic Company Information

Pyrolysis plant

Pyrolysis plant

TEL : 86-371-56771821 / FAX : --

http://www.wastetireoil.com Henan Zheng zhou China [CN]

Homepage : http://wastetireoil.com

Main Products

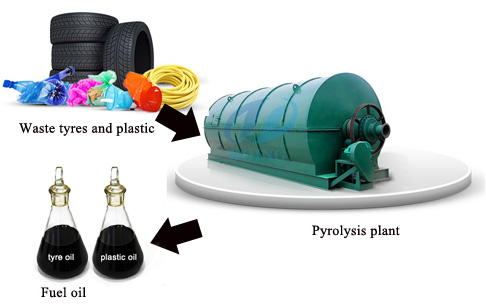

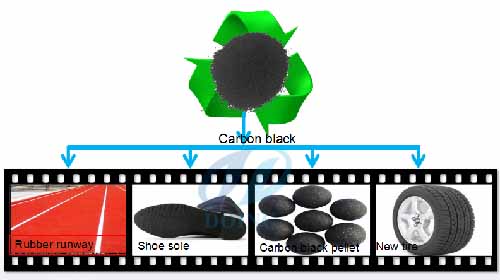

pyrolysis plant , tyre pyrolysis plant , pyrolysis plant , tyre recycling machi , plastic recycling

Company Advantage

As for the product pyrolysis plant we are sure of our pyrolysis plant about the quality .For our pyrolysis plant we have years experience to design improve the quality of the pyrolysis plant .Now we have a good control of the pressure and temperature.we have a stylish designed dedusting system which will make sure the pyrolysis plant will produce toxic gas to the environment as little as possible.What is more little energy is required for the pyrolysis plant .The natrue gas is only used at the start of the pyrolysis plant,once the machine is running it will use the energy itself to heat the reacor.And we have a stylish designed cooling system ,With years improvement we have the mature technology to control the cooling area.So we can have a higher quality oil.All the aspects of the equipment are well sealing to avoid gas leak.And we have anti-fire system to prevent the gas going back to cause accident.The pressure release system will ensure the safety of the pyrolysis plant.

ontact: Ms Bonnie

Phone: +86-371-5677 1821

+86 15893800169

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

www.wastetireoil.com

www.doinggroup.com

www.china-doing.com

www.recyclingpyrolysisplant.com

www.continuouspyrolysisplant.com

www.wasteoiltodieseloil.com

Detail Company Introduction

Henan Doing Mechanical Equipment Co., Ltd is a comprehensive enterprise related to manufacture, marketing, installation and after sale service etc.

The company is committed to developing and manufacturing of all kinds of large scale and small acale equipment. It won leading position and good reputation with its high quality products and professional service.

The main products: scrap cable wire recycling machine. PCB (Printed Circuit Board ) recycling machine. Aluminum and plastic composition recycling machine. Home electric applaince recycling machine, etc.

Scrap copper cable wire recycling machine is a kind of electric waste recycling machine for recycling scrap and waste cables and wires to clean metals and plastics for recycle use.

This copper cable wire recycling machine is apply to all kinds of scrap wire, copper wire, aluminum wire, such as automobile electric line, motorcycle electric line, storage battery electric line, waste household appliance disassembly electric line, electromechanical equipment disassembly electric line, computer cable, telephone wire, cable TV line, communication cable and other scrap wires which are difficult to recycle.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

+86 15893800169

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

www.wastetireoil.com

www.doinggroup.com

www.china-doing.com

www.recyclingpyrolysisplant.com

www.continuouspyrolysisplant.com

www.wasteoiltodieseloil.com

Factory Information

Factory Location

Factory Address

www.wastetireoil.com

Factory Size

3,000-5,000 square meters , Above 50 People

No. of R & D Staff

11-20 People

No. of Production Lines

10

Annual Output Value

US $2.5 Million - US $5 Million

Trade Information

Total Annual Sales Volume

US $5 Million - US $10 Million

Export Percentage

71% - 80%

Accepted Delivery Terms

FOB

Accepted Payment Currency

USD

Accepted Payment Type

T/T , L/C , D/P D/A , Money Gram , Credit Card , PayPal