Banana Vibrating Screen

1. Introduction of banana vibrating screen

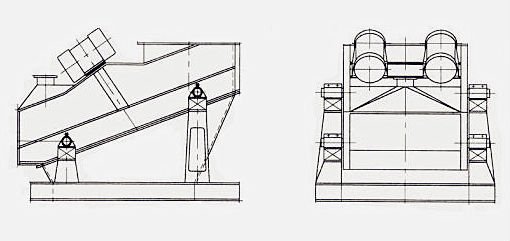

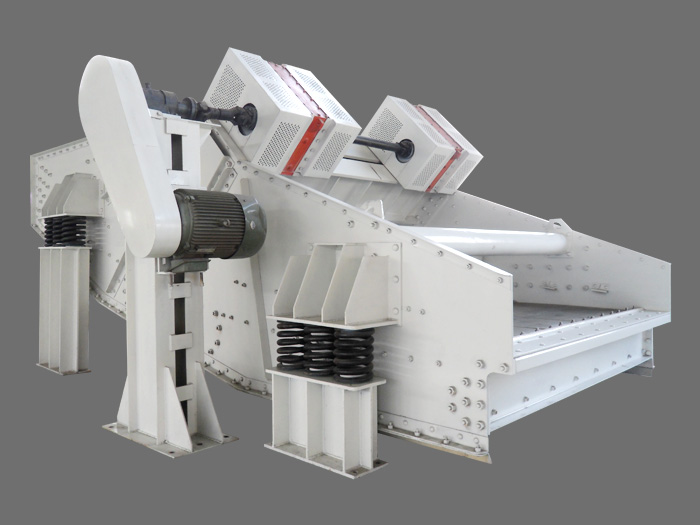

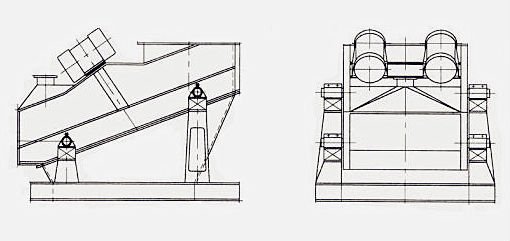

Banana vibrating screen , the shape of which is just like a banana, is a linear vibrating screen with a box type exciter, and the screen deck divide into several zones with different dip angles. From the feed end to the discharge, the ratio of materials quantity and flow speed on different zones is stable. Compared with common vibrating screen, the handing capacity can increase by 1.5 to 2 times, it is excellent for medium and fine size materials.

2. Features of banana vibrating screen

(1) Featured by high capacity and high efficiency. Under the same conditions, banana screen’s capacity is large than 40%-60% than other types of screen machine, and the efficiency is between 90% ~ 95%, reaching the advanced international level.(2) Reasonable structure, and its side plate without welding, beam all adopt the international popular UC structure, stiffness. vibrator driven beam adopts double H beam structure, side plate adopts reticular structure, which strengthen the intensity and make the structure optimization and vibration analysis.(3) High process precision. Not only can absolutely guarantee each of the parts machining precision, but also destress all machined parts and ensure the clean assembly.(4) New type vibrator. The vibrator is helical gear driven and high-power, which adopts the outer adjustable eccentric block, synchronous gear with high frequency quenching and grindingprocess to ensure that screen machine with accurate speed and amplitude smooth operation.(5) High performance, smooth operation, small partial pendulum and low noise. 3. Working principle of banana vibrating screen

Vibration screen can make the screen body periodically to-and-fro vibrate along the direction of vibrating power and make material parabola move along line direction by the vibrating motor. The screen machine consists of vibrating motor, screen frame, screen mesher and vibration isolating equipment and base frame. The side board of screen is made of high quality steel palte. High intensity bolts or rivet are used to connect side board and beam , exciting machine base. The screen machine has the advantage such as good structure and tightness.

4. Application of banana vibrating screen

4. Application of banana vibrating screen

Banana screen benefits from using utilizing linear motion combined with high vibration amplitude and high acceleration over the screen decks. This makes banana screens have a wide application and those combined features also reduce the possibility of blinding and pegging.Banana vibrating screens are suitable for dry and wet screening, sizing, dewatering and washing a variety of material ranging from gravel, coal, cement to lime stone and other aggregates. Banana screen is mainly applied to classify middle and big materials which content high percentage of very fine particles (smaller than half of the mesh hole size). Banana screen machine has simple structure, stable performance, easy maintenance and operation.At present, banana screens are available from 1~4 deck configurations and its capacity ranges from 100t/h to 1000t/h.5. Detail of product

6.Specification of banana vibrating screen

6.Specification of banana vibrating screen

|

Model

|

Feeding size (mm)

|

Handling capacity (t/h)

|

Efficient screen decks (m2)

|

Voltage (v)

|

Double amplitudes (mm)

|

|

WZDS-2060

|

<100

|

150-200

|

2.0×6.0

|

380

|

10-13

|

|

WZDS-2560

|

<100

|

200-350

|

2.5×6.0

|

380

|

10-13

|

|

WZDS-2575

|

<100

|

200-400

|

2.5×7.5

|

380

|

10-13

|

|

WZDS-2690

|

<100

|

300-500

|

2.6×9.0

|

380

|

10-13

|

|

WZDS-3090

|

<100

|

400-600

|

3.9×9.0

|

380

|

10-13

|

|

WZDS-3175

|

<100

|

350-600

|

3.1×7.5

|

380

|

10-13

|

More Information Please Contact:

Jotty Jiang

Email: jotty.jiang@hot-mining.com

Tel: +86 18381656825 (whatsApp)

Skype: jotty588

4. Application of banana vibrating screen

4. Application of banana vibrating screen

6.Specification of banana vibrating screen

6.Specification of banana vibrating screen