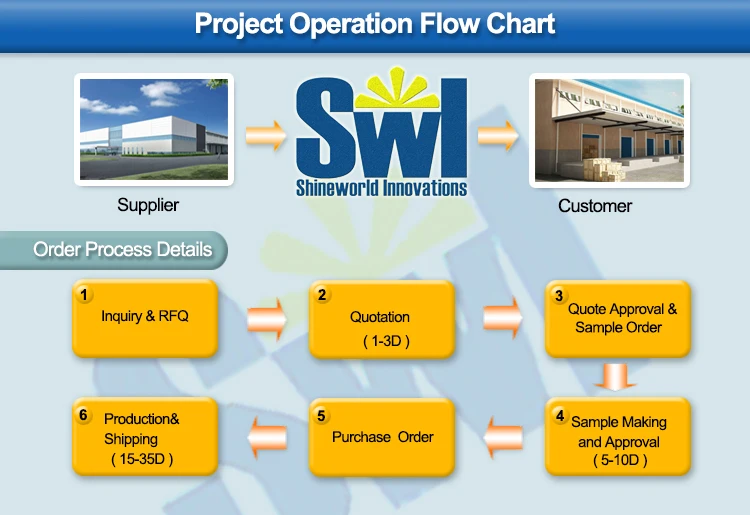

Optical bonding use liquid gel to laminate/affix the cover AR Glass, AG Glass, TP, PMMA, PC on the front of the LCD panelCan be use for outdoor display, capacitive touch panel, flat screen monitor LCD display

Benefits of optical bonding

Prevents condensation and fogging in high-humidity, salt waterImproves outdoor readability up to 400%Improves image qualityIncreases durability to withstand wide temperature, shock and vibrationIncreases impact and scratch resistance up to 300%

Enables thinner and lighter designs

Application:

Transportation, Navigation, Outdoor Kiosk, Avionics Application, Rugged Tablet PC, Marine etc.

• Increased Ruggedness (up to 300%): Bonding a sheet of glass on top of the display increases the ruggedness of the display.• Improved Durability: A bonded display is better able to resist scratches, fluids, stains and dirt.• Condensation: The elimination of an air gap between the cover glass and the display means that moisture cannot Penetrate and cause fogging on display’s surface.• Increased Sunlight Readability (up to 400%): By reducing the amount of reflection, the contrast of the bonded display is enhanced. The higher the contrast, the easier it is to read to display screen.• Extended Temperature Range and EMI Filtering: The temperature range of the display can be extended by incorporating ITO heaters on the cover glass; EMI filters can be added via the same mechanism.

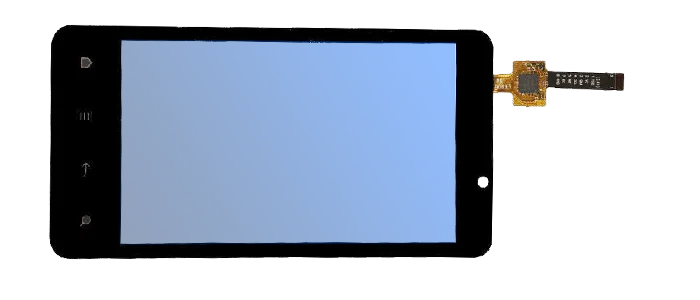

Structure: Glass-Film-FilmApplication: Mobile

Structure: PET-GlassApplications: Pad, Home & Building Security, Automotive

Structure: Glass-GlassApplications: Pad, Home & Building Security, Automotive

Structure: PC-OCR-GlassApplications: Medical Device

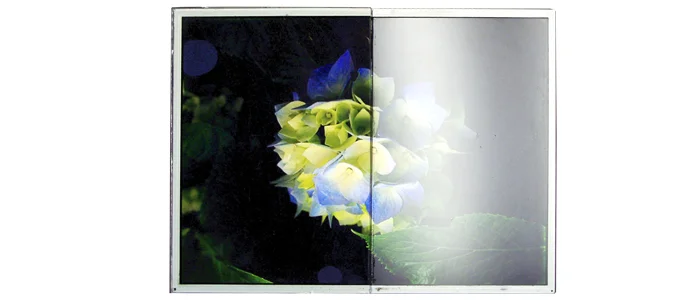

Structure: AG+AR Glass-OCR-LCMApplications: Outdoor Display

Structure: AR Glass-OCR-LCMApplications: Outdoor Display, Advertisement Panel

Structure: Cell-OCR-Cell Optical BondingApplication: Naked Eye 3D Panel

Structure: CTP-OCR-LCM Optical BondingApplication: High-end Electronic White Board