One Component MS Sealant for Construction Joint Sealing

MS365UV is a single-component sealant preparation based on SIPE resin, which known as MS or SMP (Silane-modified polyether) as the main component. It has black, white and gray three colors for choice. It has good flexibility, good adhesion with cement, stone and a variety of substrates, the cured sealant without bubbles.

Key Features

1. One component, excellent extrusion and thixotropy, convenient to apply2. Environmental protection, solvent-free, silicone-free, no pollution the substrate, the surface is paintable3. Excellent weather resistance and durability4. Excellent extrudability, easy to scratch sewing operation5. Low modulus, good anti-displacement ability

| PROPERTY | LIMITS | VALUE |

| Color/state | Black/white/gray, paste | / |

| Density (g/cm³) |

Standard values±0.1 |

/ |

| Extrudability (ml/min) | ≥100 | 200 |

| Sag (mm) | 0 | 0 |

| Tack free time (hr) | 1~3 | 2 |

| Mass loss rate (%) | ≤2 | 1 |

| Hardness (Shore A) | 15~40 | 30 |

| Tensile modulus (MPa) |

20℃ | ≤0.4 (60%) |

0.30 |

| -23℃ | ≤0.6 (60%) | 0.50 | |

| Modulus cohesiveness | No damage | No damage |

|

Modulus cohesiveness after immersion in water |

No damage | No damage |

|

Cohesiveness after cold drawn & hot press |

No damage | No damage |

|

Elastic recovery (%) |

≥60 | 60 |

|

Stretch - compression cycle performance |

No damage | No damage |

|

Modulus property in water - ultraviolet radiation |

No damage | No damage |

|

Operating temperature |

-40~+90 °C | 90 °C |

Directions of Use

Tool: Manual or pneumatic plunger caulking gun1. Clean and dry all substrate surfaces by removing foreign matter and contaminants such as oil dust, grease, frost, water, dirt. 2. Ambient temperature and humidity could affect the touch dry time and curing. If the temperature and humidity is too low, the curing speed will be slow. On the contrary, the higher temperature, the touch fry time is faster, make sure the construction environment temperature between 5~35°C, humidity between 50~70%RH. At temperatures below 5°C, is recommended heating the product by place in a 30~40°C environment for 1 hour (should be less than 3 hours) before use.For cartridge1. Cut nozzle to give the required angle and bead size2. Pierce the membrane at the top of the cartridge and screw on the nozzle3. Place the cartridge in an applicator gun and squeeze the trigger with equal strengthFor sausage1. Clip the end of the sausage and place in barrel gun2. Screw end cap and nozzle on to barrel gun3. Using the trigger extrude the sealant with equal strengthAttention of operation1. The nodes parts can be modified and strike off to smooth by scraper or hard foam strip. Smoothen small details section with soapy water.2. Need to do compatibility testing before painting construction.3. Must be used in conjunction with the base surface treatment agent

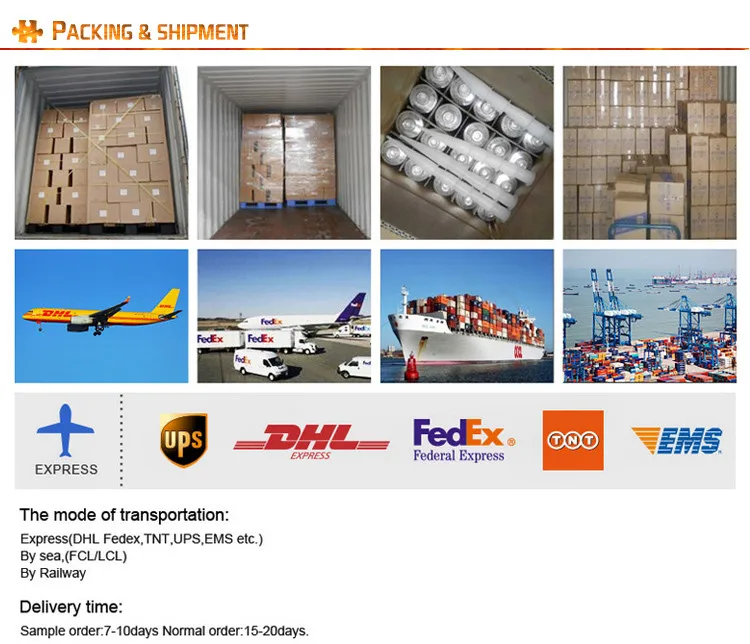

310ml cartridge, 600ml sausage 20pcs/carton

When stored at 5~25°C, humidity≤50%RH in the original unopened containers, this product has a usable life of 9 months from the date of production. Do not store at temp. over 25°C, humidity over 80%RH.

Transportation: moisture proof, prevent the rain, prevent sunscreen, anti-high temperature, away from heat, handle with care, crush or collision is prohibited.

Q: Can I get samples?

A: YES! Usually a certain quantity of FREE sample would be provided to our customers to varify the quality .

Q: What's the delivery time?

A: Normally within 15-20 days since receive the purchase order and deposit. (except the force majeure).

Q: Can you do OEM lable for the products?

A: YES, the OEM service such as buyer labels are accepted as long as your order reach our standard amount.

Any more questions, please contact us anytime! +86-400 882 1323

>>>>>Odorless Bonding, Healthy Living.<<<<<