Transparent Conductive Film Vacuum Coating Machine Optical Thin Film Coating Equipment

This equipment is designed for coating precision optical thin film,each system unit and overall structure well meet the optical thin film production process requirements,which suitable for coating anti-reflection film, bandpass film ,IR-Cut filter etc.It equipped with high-precision film thickness control system,excellent performance electron gun,high degree automation coating control system, etc. It's the ideal equipment for coating high precision optical thin film.

|

Model |

ZZS-920 Optical thin film coater |

|

Vacuum Chamber |

SUS304,Φ920mm×H1000mm |

|

Substrate Dome Size |

Φ870mm |

|

Substrate Dome Rotation Speed |

3rpm to 30rpm(Variable) |

|

Optical Film Thickness Control System |

SQC310+6point rotary sensor,full automatic coating control system |

|

Evaporation Source |

5kw EB source: 1 units, resistance evaporation |

|

Vacuum System |

Rotary Pump + Roots Pump +Diffusion Pumps |

|

Performance |

|

|

Ultimate Vacuum |

4.0×10-3Pa |

|

Recover vacuum |

From atmosphere to 4 x 10-3 Pa≦12min. |

|

Substrate Heater |

350℃ (max.) |

|

Utility |

|

|

Power Requirements |

three-phase ,220V/380V±5%,50HZ |

|

Cooling Water Flow Rate |

100 /min or greater |

|

Compressed Air Pressure |

0.6~0.8MPa |

Optical Thin Film Application:

1.For clean energy:

Transparent conductive film, IR cut coating, decoration coating etc.( LED )

2.For display:

AR Coating, Dichroic Mirror, PBS, Cold Mirror etc.

AR/AS(AR/Anti Electromagnetic wave coating) etc.

ITO Transparent Conductive Film etc.(Optical parts and lenses in liqid crystal)

3.For Optical Communication:

NBPF, BBPF, Edge filter, AR Coating, GFF etc.( DWDM Filter )

4.Semiconductors:

AR Coating, BPF, Edge filter, HR Coating etc.(lenses and optical parts for semiconductor industry facilities laser, optical switch)

5.Optical Storage Media:

AR Coating, BS Coating etc.( optical parts and components for optical disks such as DVD,CDRW,CDR,CD)

6.For Bio-Industry :

BPF,Edge filter,AR Coating,Mirror, HR Coating,Cold Mirror etc.( Optical parts and lenses in liqid crystal projectors,liquid crystal displays, organic electro luminessences)

7.For Vehicle-mounted device

Flat plate display,Vehicle-mounted camera,panel

Company introduction:

Chengdu Guotai Vacuum Equipment Co.,Ltd is a large vacuum coating equipment company ,which is collection of research & development ,production,marketing,and after-sales service of integrated.

We are focus on manufacturing Optical Vacuum Coating Equipment,Winding VacuumCoating Equipment,Continuous Coating Production Line,Magnetron Sputtering Vacuum Coating Machine,Vacuum Electric,Vacuum Parts and Consumables etc.Machine produces film which widely used in electro-optical system and thin film instruments,such as digital cameras,digital video,binoculars,projector,energy control,optical communication,display technology,interferometer,satellite missiles,semiconductor laser,mems,information industry,laser production,various kinds of filter,lighting industry,sensors,architectural glass,automotive industry,decoration,glass lens,metal,resin,ceramic,etc.Good quality products and excellent after-sales service make company market share increasing by 35% per year.Except sale equipment ,we also undertake a variety of optical coating services.

We adhere to honesty,quality first as spiritual idea,innovation,dedication,harmony and win-win as principle,provide high quality products and excellent service to each customers.Chengdu Guotai Welcome your come.

Workshop show

Our team

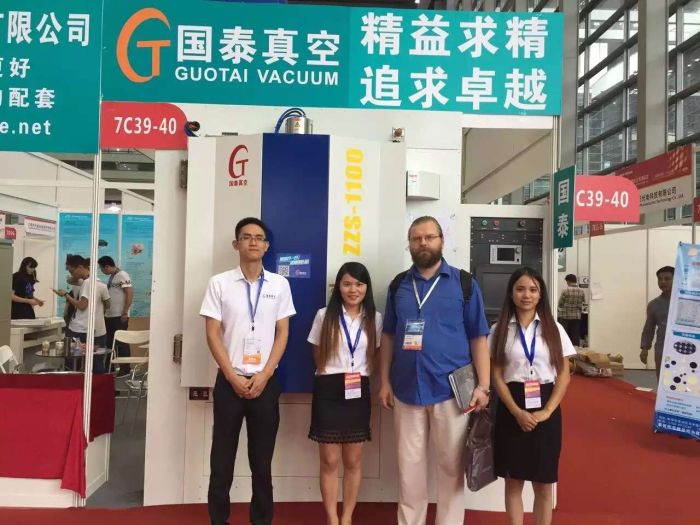

Customer visit

Exhibition

Certification

Package show

Note:

1.We have more optical vacuum coating machine models,such as ZZS500,ZZS630,ZZS800,ZZS900,ZZS1100,ZZS1300,ZZS1600,ZZS1800,ZZS2000,ZZS2350.

2.Equipment final size and configuration customized production according to your requirements,we also undertake all kinds of optical coating film service.

Acceptance Process: After machine making ,Seller will inform buyer to come to factory to check, at that time it can be testing for coating sample ,in user factory as the final checking. Seller must install ,testing on time and on the quality .After the whole machine be installed ,tested ,please buyer depend on the technology agreement and acceptance criteria.

What we can do for you ?1.Installation: The supplier should send engineers to buyer's factory and help installation, commissioning and support of the production process. The round tickets, room and food should be to be paid by buyer. The buyer should assist and cooperate when needed.2.Traning:during installation ,operator and maintenance man must full participate .supplier will provide traning in the locale including daily operation ,maintenance ,operation problem analyze and process of urgency.3.After sale service: One year guarantee ,it will offer the best service in the guarantee or past guarantee .Due to improper use, or other damage to the equipment not itself no warranty, wearing parts is no in the repair. Guarantee begin to the machine finish testing .