Specifications:

1. Item Name > Titanium Bicycle Bike Derailleur Hanger Frame Rear Dropouts

2. Material> titanium

3.Thechnologies> investment casting&sand casting& graphite mould casting, CNC, 3D printing, superlastic forming technology, etc

4. Grade>GR1, GR2, GR5 ,GR9(TA1, TA2, TC4)

1.HRC: 40-41

2. casting accuracy: ZT6

3.CNC mini-tolerance: +/-0.005mm

4. Casting mini-tolerance: +/-0.1mm

5. Surface roughness: Ra =1.6

6.mirror polishing: Ra=0.6

7.annual output: 60000 pieces

8.welcome to our factory for meeting

Quality control:

1. Before confirming the order, material and color should be check strictly through sample2. Quality will be controlled from the beginning to the end.

3. Every parts will be checked and cleaned before packing into the carton4. Before shipping ,the clients could send a QC or point to the third party to check the quality.

OEM/ODM service

We are a professional OEM/ODM factory with rich experience in investment casting of various metals, alloys, especially titanium , we assure you of our best service at all time.Welcome your drawings or samples.

Our Star Materials:

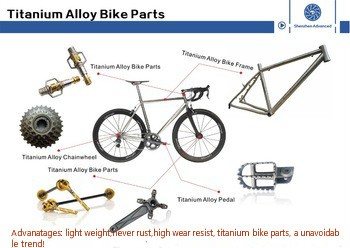

titanium alloy:light weight,corrosion resistance,high strength,high wear resistance,high temperature resistance,rust-proof and so on

Why titanium?

1. Light weight and hard surface!

Titanium's relative weight, at minimum, is 40% lighter than Stainless Steel. As mentioned above, Titanium has the highest strength/weight ratio of any metal.

2. Eco-friendly!

Titanium is no harm to the human body. Using titanium products can make you feel ease, relax your muscle and improve your motor function.

3.Strong and firm!

Titanium is approximately 40% stronger than Stainless Steel, depending on the relative grades of the two metals. In fact, Titanium has the highest strength/weight ratio of any metal.

4.Corrosion resistance,rustproof, it saves your money!

Since Titanium will never corrode, you won't be spending your hard earned money for replacement parts that have been destroyed by rust and corrosion. Titanium: "You deserve own it."

Unlike stainless steel, titanium is stronger, lighter and completely corrosion free in the natural environment.

Investment casting has quite impressively stood the test of time –of the Ages, really. It remains a valued tool in the arsenal of engineers in virtually every industry for several, very good reasons:

Complex Geometries: Investment casting can easily create intricate shapes, internal passages, and complex surface features to near net tolerances without the addition of costly secondary operations.

Integrated Design: Design engineers use the flexibility of the investment casting process to integrate part designs. Machined features and multiple welded components can be integrated into a single casting to eliminate the need for multiple components and complex assemblies. Elimination of weldments alone can increase the strength and service life of your products.

Reproduction of Detail: Graphics, surface textures, splines, teeth, and a variety of detailed surface features add form and function to your components. Net shape details are reproduced with exceptional accuracy.

Alloy Control & Flexibility: Processing your parts from the liquid state gives investment casting unique advantages. Modified alloy compositions are easily accommodated to engineer the mechanical and corrosion resistant properties of your products. Novel cooling methods can engineer grain size and orientation to tailor properties and increase fatigue life.

Why us?

Our advantages:

Good News: Our technical team solved several key engineering challenges in investment casting industry this year to make a breakthough, which saves our cost and keep the high quality and we will off you a much more favorable price!

1.We are a factory not a trading company that our cost is lower and

the efficiency is higher by reducing intermediate link.

2. We have patented technologies of various titanium alloys forming , which ranks one of the top level in domestic and international technologies.

3. There are some professors and doctoral engineers with years of rich experience in casting production in our company.

4. We are in close cooperation with Harbin Institute of Technology(HIT) - solid titanium casting technology research and development center.

|

Our products |

Titanium and titanium alloy casting, nickel and cobalt base superalloy, stainless steel, heat resistant steel, high-alloy steel, iron casting, copper and aluminum alloys. |

|

Main Products and technology |

investment precision casting, sand mold casting, Metal type and centrifugal casting, all kinds of titanium and rare metal(e.g. Niobium, tantalum,molybdenum, tungsten, nickle,cobalt etc) bar, plate, wire, welding material. |

| Titanium Grade | GR1, GR2, GR5 (TA1, TA2, TC4) |

| Standard | ASTM,GB |

| Application | Automotive, aerospace, medical, petroleum, sports, life and integrated application. |

Company View:

Honors:

Our other products application

Company capability

1. Trade capacity

Trade & Market

| Main Markets | Total Revenue (%) |

|---|---|

| Domestic Market | 30.00% |

| Eastern Asia | 13.00% |

| Southeast Asia | 10.00% |

| South Asia | 8.00% |

| Western Europe | 7.00% |

| North America | 6.00% |

| Africa | 5.00% |

| Mid East | 4.00% |

| Eastern Europe | 4.00% |

| Northern Europe | 4.00% |

| Southern Europe | 3.00% |

| South America | 3.00% |

| Central America | 2.00% |

| Oceania | 1.00% |

| Total Annual Sales Volume: | US$5 Million - US$10 Million | |

|---|---|---|

| Export Percentage: | 61% - 70% |

2.Production Capacity

| Factory Size: | 3,000-5,000 square meters | |

|---|---|---|

| Factory Location: | Building 2C in Russia Industrial Park, No. 22 Tianping Road, High-tech Industrial Development Zone, Harbin, Hei Longjiang Province, China | |

| No. of Production Lines: | 3 | |

| Contract Manufacturing: | OEM Service Offered Design Service Offered Buyer Label Offered | |

| Annual Output Value: | US$5 Million - US$10 Million |

There are 5 - 10 doctorial professional R&D Engineers with more than 20 years experience in our company.

Packaging details: wooden box or cartons

Shipping details: 30-40 days after order confirmed

1. Raw drawing of your products.