1. Material: Titanium

2. Technics: Precision dewaxing casting, CNC

3. Surface finish: Polishing(mirror), passivation, acid cleaning, temper

4. Surface roughness: Ra 1.6

5. Casting minimum tolerance: +/-0.1mm

6. CNC minimum tolerance: +/-0.005mm

7. Inspection: Slide caliper, microcaliper, projector, 100%

8. Certification: ISO9001:2008

9. Package: Box, wood crate, rust prevention

10. OEM Service: We can produce it according to your drawings or samples.

11. OEM/ODM available.

Technical Info

| Products | Titanium and titanium alloy casting, nickel and cobalt base superalloy, stainless steel, heat resistant steel, high-alloy steel, iron casting, copper and aluminum alloys. |

| Titanium Grade | GR1, GR2, GR5 (TA1, TA2, TC4) |

| Standard | ASTM,GB |

| Advantages | 1. company technical staff has a professor and 3 doctoral, Engineers with years of experience in casting production. |

| 2. Our company mastered various titanium alloys forming patented technology, patent technology level of the leading domestic and international advanced; | |

| 3. The company relies Harbin Institute of Technology(HIT) - solid titanium casting technology research and development center. | |

| Application | Automotive, aerospace, medical, petroleum, sports, life and integrated application. |

| Main Products | investment precision casting, sand mold casting, Metal type and centrifugal casting, all kinds of titanium and rare metal(e.g. Niobium, tantalum,molybdenum, tungsten, nickle,cobalt etc) bar, plate, wire, welding material. |

| Titanium features | 1. Light weight and hard surface |

| 2. Eco-friendly, Strong and firm | |

| 3.Corrosion resistance,rustproof |

Our advantages:

Good News: Our technical team solved several key engineering challenges in investment casting industry to make a breakthough, which saves our cost and keep the high quality and we will off you a much more favorable price!

1.We are a factory not a trading company that our cost is lower and

the efficiency is higher by reducing intermediate link.

2. We have patented technologies of various titanium alloys forming , which ranks one of the top level in domestic and international technologies.

3. There are some professors and doctoral engineers with years of rich experience in casting production in our company.

4. We keeps the higher quality of our products when the price is the same to others' and keeps a lower price when the quality is same to others' because of our exclusive patents of the high technologies.

5. We are in close cooperation with Harbin Institute of Technology(HIT) - solid titanium casting technology research and development center.

Office Overview

Factory Plant and Casting Process

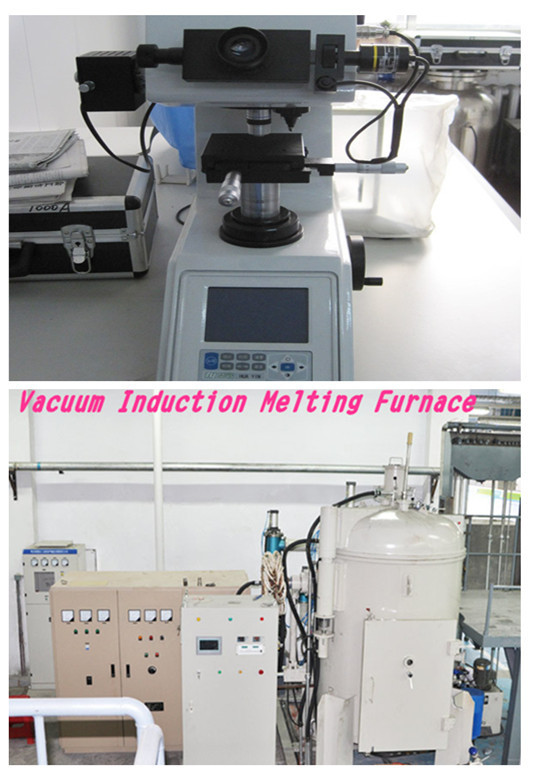

Equipment

Patents and ISO Certification

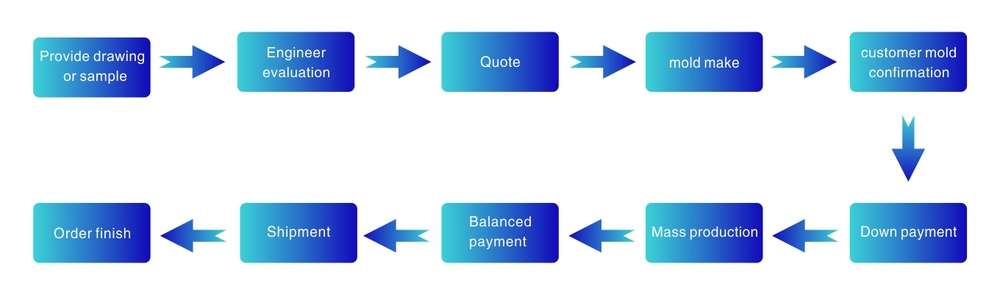

1. Raw drawing of your products.

Investment casting has quite impressively stood the test of time –of the Ages, really. It remains a valued tool in the arsenal of engineers in virtually every industry for several, very good reasons:

Complex Geometries: Investment casting can easily create intricate shapes, internal passages, and complex surface features to near net tolerances without the addition of costly secondary operations.

Integrated Design: Design engineers use the flexibility of the investment casting process to integrate part designs. Machined features and multiple welded components can be integrated into a single casting to eliminate the need for multiple components and complex assemblies. Elimination of weldments alone can increase the strength and service life of your products.

Reproduction of Detail: Graphics, surface textures, splines, teeth, and a variety of detailed surface features add form and function to your components. Net shape details are reproduced with exceptional accuracy.

Alloy Control & Flexibility: Processing your parts from the liquid state gives investment casting unique advantages. Modified alloy compositions are easily accommodated to engineer the mechanical and corrosion resistant properties of your products. Novel cooling methods can engineer grain size and orientation to tailor properties and increase fatigue life.

|

Packing |

wooden box; paper box; gift box or packing as customer requires |

|

Transportation |

By express like DHL UPS FEDEX TNT EMS |

|

By sea or by air (for large order) |

|

|

Be able to ship as customer requires |

|

|

Term of payment |

100% T/T to Bank, Western Union |

|

30% deposit T/T, 70% balance before shipping for large order |

|

|

Delivery time

|

7days working days after payment done for samples |

|

30-35 days for large order producing |

1 Great innovation capabilities : scinece and technology institute (The first Research Institute of Harbin)and univeristies (Harbin Engineering University and Harbin Institute Of Technology)

2 Complete titanium alloys, nickel-based alloys, steel, aluminum and other materials, precision casting production lines

3 Successful cooperative case and partners: AVIC HAIG,China Gas,China Aerospace Science & Industry Corp. and China Sinopec Group,etc.

4 High qualified R&D design, sales and customer service team

5 Quik-response:All the mails and inquiries will be replied within 24 hours