Similar to filter disc, conical strainer also can be made of multi layers. The filter, also known as cone filter, can be manufactured in almost any specifications. And it is made of high quality raw materials including perforated metal mesh, stainless steel woven wire cloth, due to which it can withstand harsh conditions. It is mainly used to filter out pollutants and the sludge particles and can be divided into sharp bottom conical shape and flat bottom conical shape.

It takes the advantages of good permeability, high holding capacity and can be recycled after cleaning. Because of its durability, the conical strainers are generally used for high-velocity fluid filtration in pharmaceutics, chemical industry, agricultural chemical and foods industry, etc.

Specification

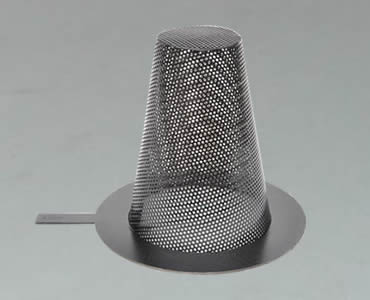

CS-01: Conical strainer with flat bottom.

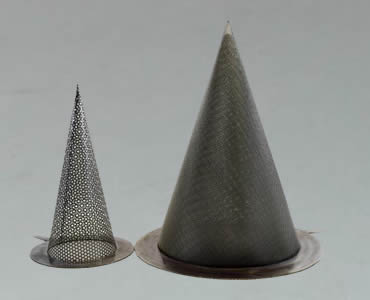

CS-02: Conical strainer made of fine woven mesh cloth.

CS-03: Conical strainer with sharp bottom.

CS-04: Conical strainer without handle shank.

CS-05: Conical strainer with two open ends.

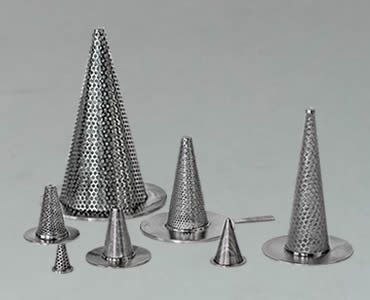

CS-06: Conical strainer made of perforated mesh.

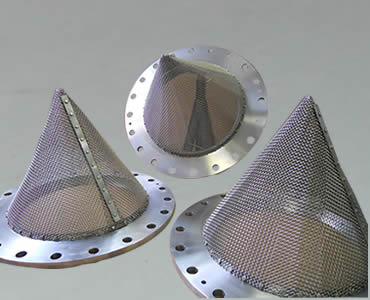

CS-07: Conical strainer made of black mesh cloth.

CS-08: Conical strainers made in different sizes.

CS-09: Conical strainer manufactured with flange.

CS-10: Conical strainer with stainless steel edge.

Features

ApplicationThe conical strainer can be widely used in various industries sectors, such as purification, chemical, aviation, petroleum, metallurgy, gas-solid, liquid-solid, and gas sampling collection, gas-liquid separation cooling, gas distribution, fluidization bed, shock reducing, inflaming retarding.