Wheat Bran Corrugated Steel Silo Cost

we promise to offer you the best quality and service, not the lowest but the most reasonable price

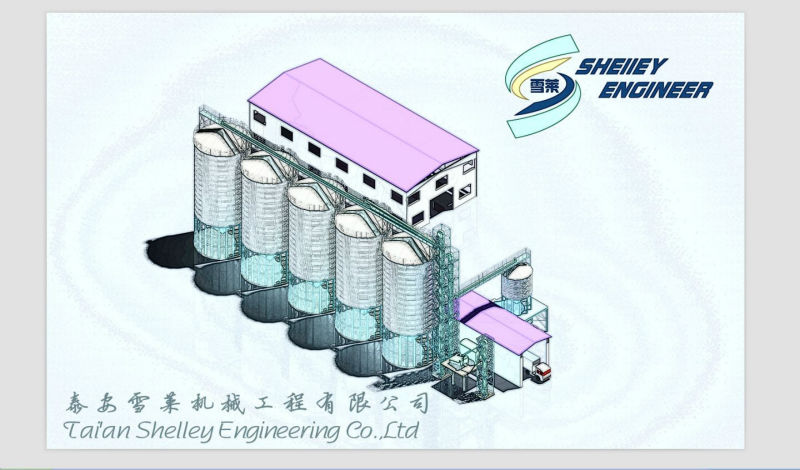

Tai'an Shelley Engineering Co., Ltd- your steel silo storage expert!

Taian Engineering Co.

We manufacture steel silos, from small transportable silos holding a few tons to large, built on-site structures holding thousands of tons; elevated or on ground silos; silos to store grain, prepared feeds, feed supplements, fertilizer and the list goes on....

Flat bottom silo& Specification

|

Silo type |

Flat bottom silo |

|

Diameter |

3.6-20.1m |

|

Capacity |

30t-10682t |

|

Volume |

39m3-13873m3 |

|

Accessory Equipments: |

|

|

- Bucket Elevator with capacity from 1 tone/hour to 400 tone/hour- Chain Conveyor with capacity from 1 tone/hour to 400 tone/hour- Screw Conveyor with capacity from 1 tone/hour to 200 tone/hour- Elevator Towers- Electrical and Manuel controlled Slide gates- Distributors with 1 in 2/3/4/5/6 out- Catwalks- Spout Pipes |

|

|

Machines: |

|

|

- Mill Machines with capacity from 5 tone/hour to 50 tone/hour- Pellet Machines with capacity from 5 tone/hour to 50 tone/hour--Level sensors, aeration system with centrifugal fan, temperature control system and sweep auger, dedusting system as an option. |

|

Some of Projects finished

Features and Advantages

Flat bottom silo can support more capacity, which up to 10000tons, and cheaper than hopper bottom silo.And it need a sweep auger to run the grain out.

1. Lower basic cost with lightweight, low request for foundation, low consumption of steel.

2. We can produce the standard components which can be installed on-the-spot.

3. Simple, easy and efficient to install within a short amount of time due to superior component design which are connected by standard bolts.

4. Easy to remove or repair with standard bolts.

5. Low cost and long tenure of use. The cost of bolted silo is just 35%-50% of the cement silo with the same specification; and its life span can reach 30 years.

Structure of silo

1. The Silo Body

Include the wall plate, column, manhole, roof ladders and so on.

(1) The wall plate

Our steel is hot galvanized, which makes it durable and weather resistant. Our advanced bolts with spherical washer and the resisting-worn rubber are used to ensure the tightness and using period.

(2) Column

The column, made by the Z-bar, is used to reinforce the silo body. It is connected by junction panels.

(3) Manhole and Roof Ladders

There are inspection door and ladders inside and outside the silo body. It is convenient and accessible for any maintenance work.

2. Roof

Roof is made up of radiated beam, roof cover board, tension ring, ventilator scoop, roof cap, etc.

The space age construction technology, which is adopted in the design of the silo framework, can ensure the stability of silo under the large span. There is a guardrail around the silo eaves and there is also a manhole on top of the roof.

Customers

welcome to visit us, we are always here waiting for you!!